11. Hook height

Before adjusting the looping stroke as well as the needle bar height

and particularly after needle breakage it is necessary to check the

correct hook height.

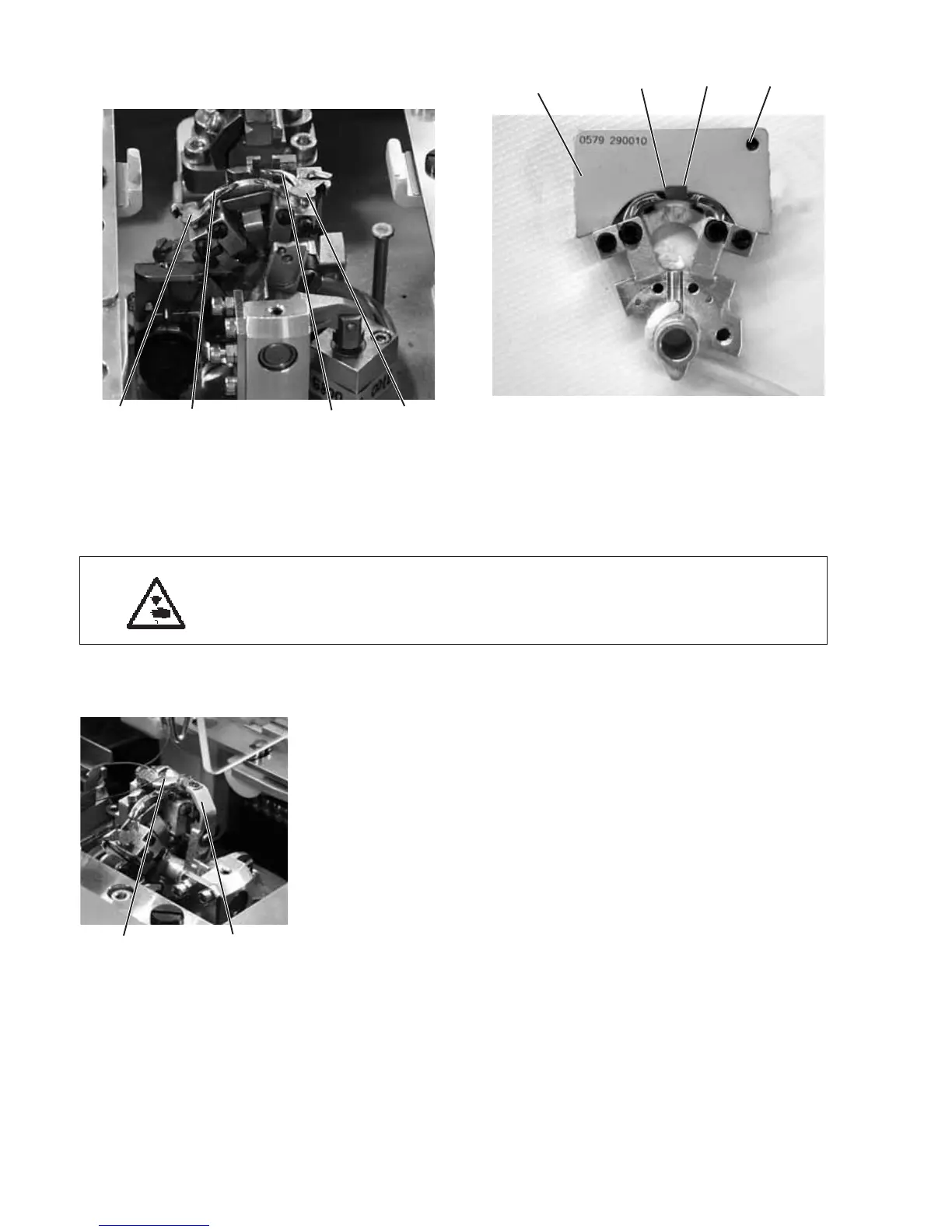

Use gauge 2 for checking the hook height.

Caution: Danger of injury !

Switchthemainswitchoff.

Adjust the height of the hook only with the machine s witched off.

Standard checking

When the gauge is put on the hook supports, please observe the

following:

–

The drill-hole 1 of the gauge must be on top right.

–

The tip of the left hook must be under the edge 3 of the gauge.

–

The tip of the right hook must be under the edge 4 of the gauge.

–

The hook tips must just abut on the gauge.

–

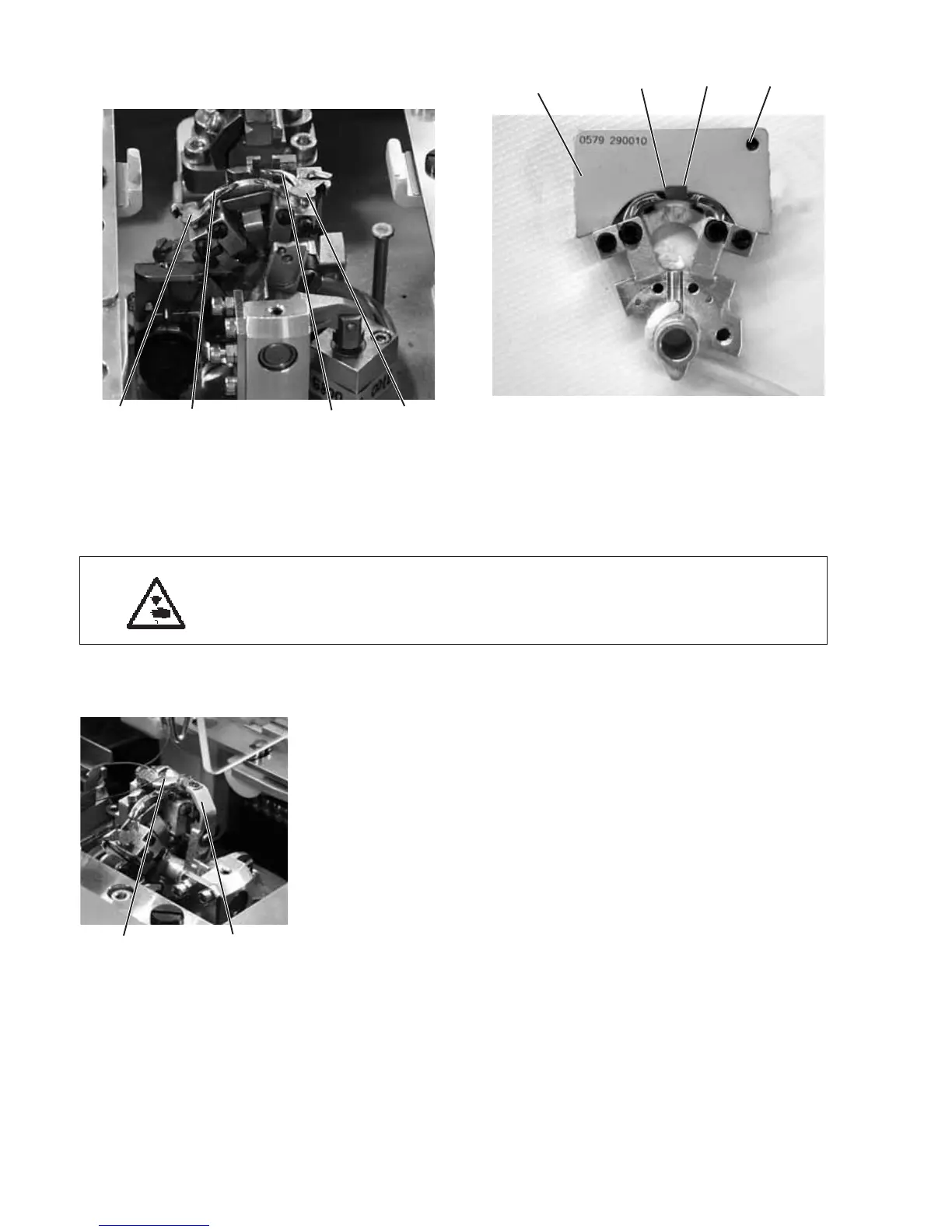

Remove the thread trimmer 9, the throat plate 10, the s preader

stops 5 and 8 as well as the spreaders 6 and 7 from the hook

supports.

–

Bring the needle bar in position “up” by turning the handwheel.

–

Put the gauge 2 on the hook support with the hooks inserted in the

hook supports as far as it will go.

–

In this position the rules mentioned above must be fulfilled.

Correction

–

Adjust the correct hook height by slight alignment of the hooks.

34

2341

87 6 5

10 9

Loading...

Loading...