. .

Dyadic Systems – Mechatronics Cylinder Manual MF-005500-EN-62/63

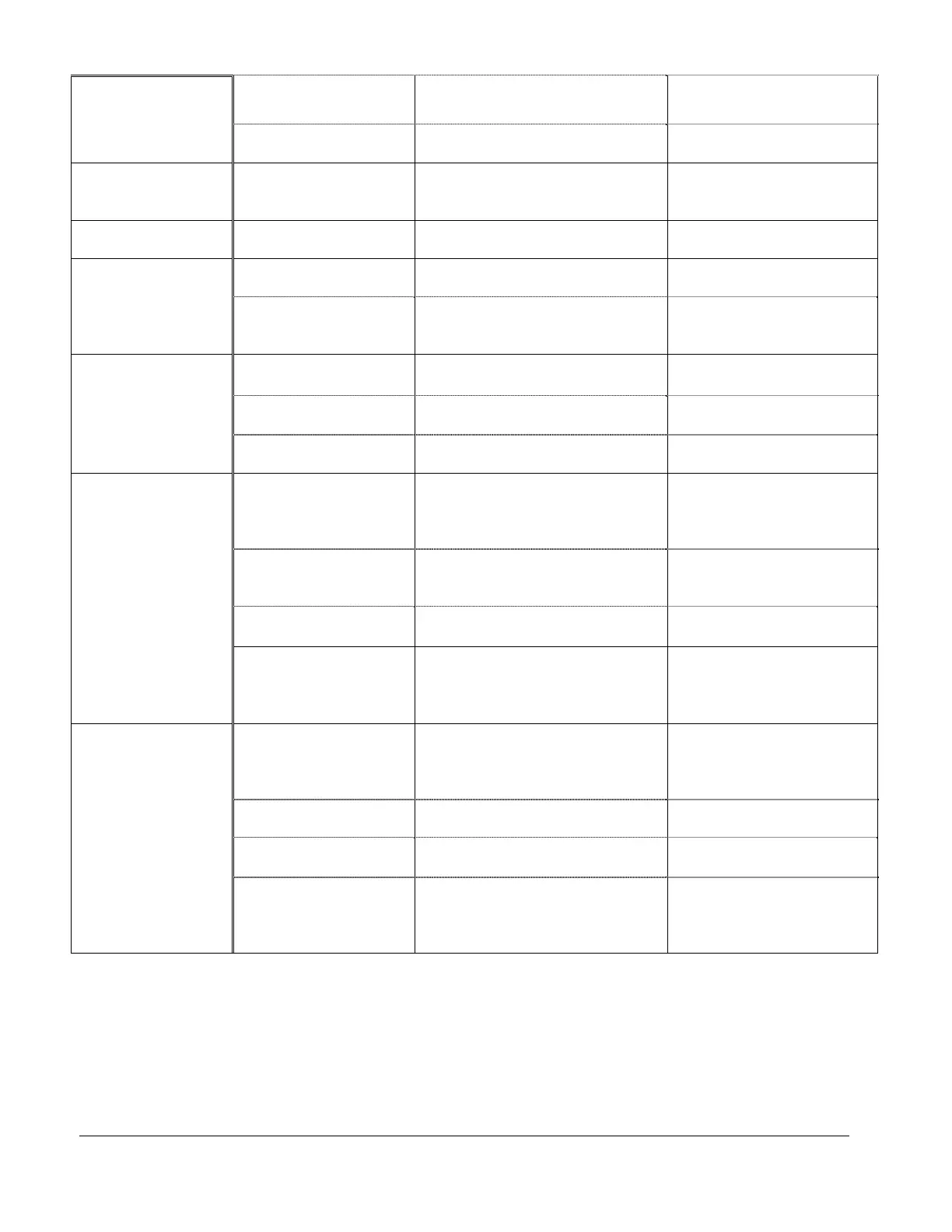

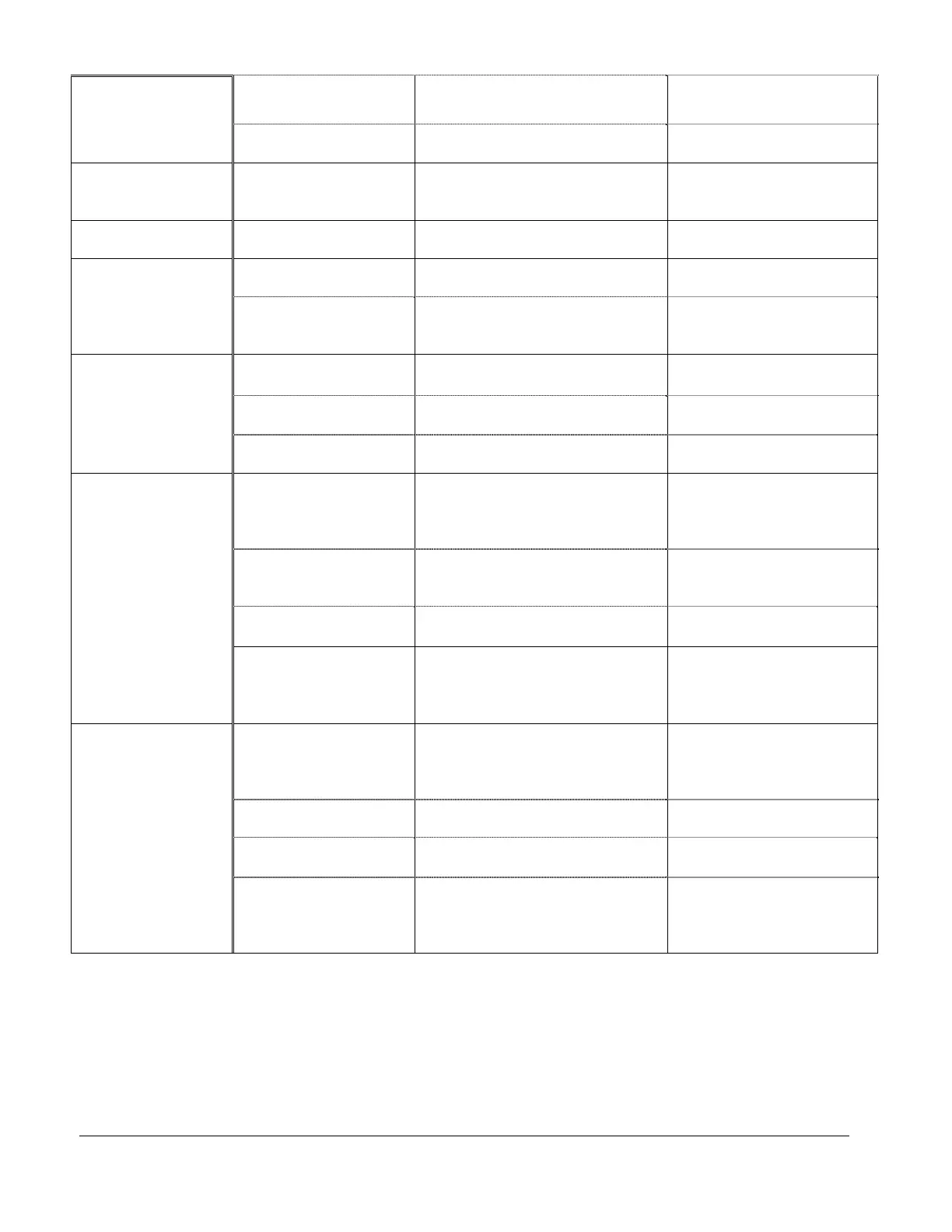

Over load Try to run Cylinder only without

any load

Load to be within specs

No movement signal Check position program Position program to be

corrected

Cylinder moved just

a moment but

stalled

Wiring is wrong Wiring to be corrected

Unstable Cylinder

motion

Wiring connections are

not stable

Check connections (Terminals,

connectors, etc.) and wiring

Wiring to be corrected

Cylinder vibrates Servo Gain is too high Check Gain Reduce Gain – factory

default is 6

Cable gets noise from

other equipment

Test with other equipment off or

isolated

Route cable away from

noise source and/or Cable

to be shielded

Cylinder heats up Ambient temperature

is too high

Check the ambient temperature Lower the ambient

temperature to under 40°C

Cylinder surface is not

clean

Check the appearance of

Cylinder

Remove dust, oil etc. on

the surface of Cylinder

Overload Try to run Cylinder without any

load

Reduce the load and/or

review the guiding design

Abnormal noise Mounting is loose Check the mounting of Cylinder

and other machine,

Loose mounting screws,

incorrect concentricity, etc.

Correct the mounting

and/or joint to load

Other machine

/equipment is vibrating

Check the moving parts of other

machine

Check with the

manufacturer of other

machine

Defective Cylinder Try to use other good Cylinder Replace product

Cylinder hits the over

stroke limit end due to

over run

Reduce the

Acceleration/Deceleration of

Cylinder

Correct position accel

/Deceleration

SIO communication

is not valid

Communication

method is not suitable

Check if output of main control

system is RS485

In case of main control

system RS232C, use a

protocol converter for

communication

Output port # is set

wrong

Correct output port number

and setting

Wrong axis number Correct axis number

Reply time of Cylinder

is longer than receiving

time of upper control

System (PC)

Check if longer receiving time of

main control system (PC) helps

to communicate

Set shorter reply time of

Cylinder

REFERENCE:

Action 1 – Shaft Seized

1. In this condition the actuator won’t move. If this condition continues, the over-load alarm (code

E0) will be output. If the problem (shaft seized) is not resolved when the main power is cycled

(shut down and turned back ON), the encoder counter error (code B9) will be output.

Loading...

Loading...