FUEL SYSTEM

CS-2511TES

251Ts, 251TCs

39

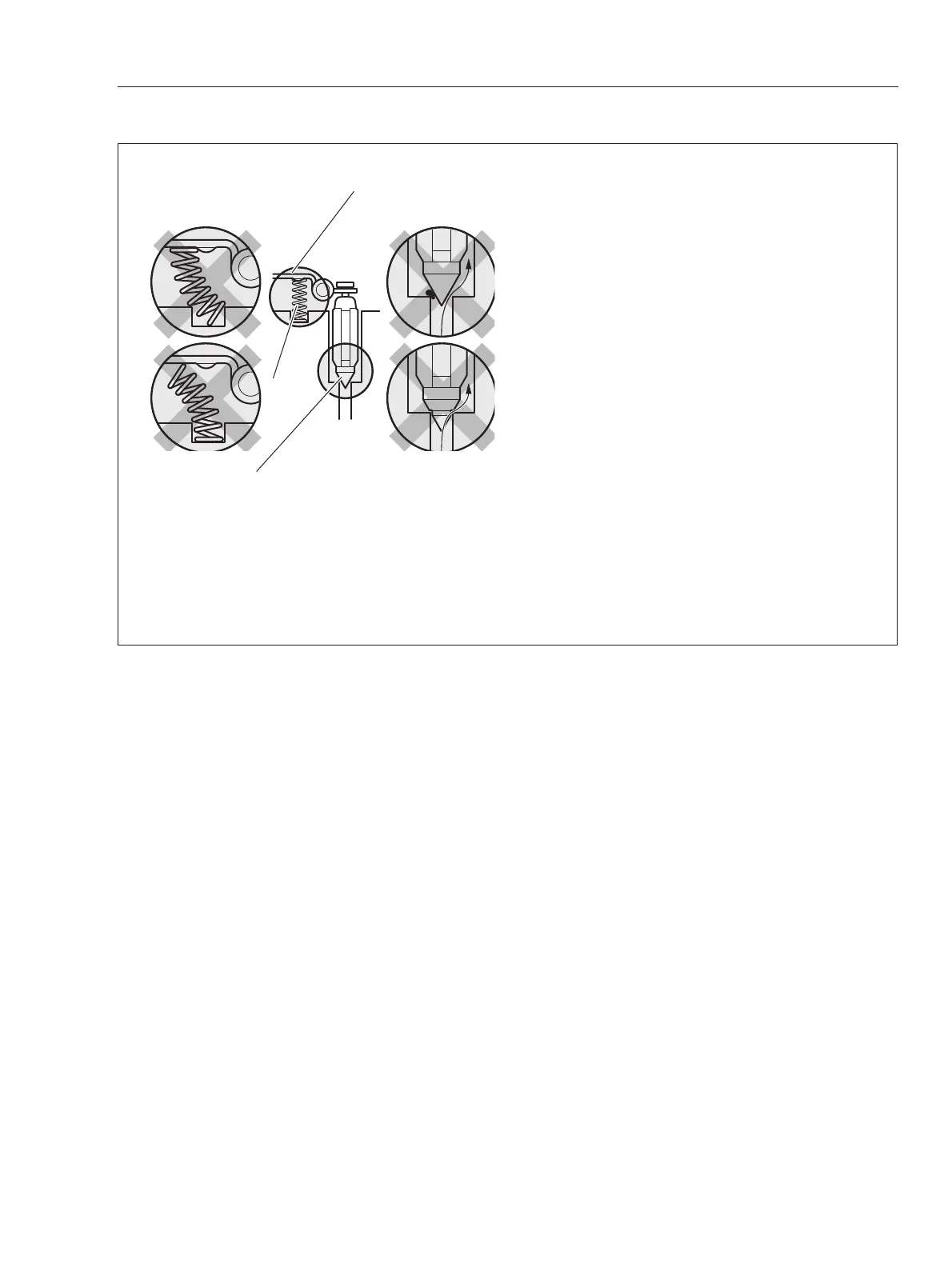

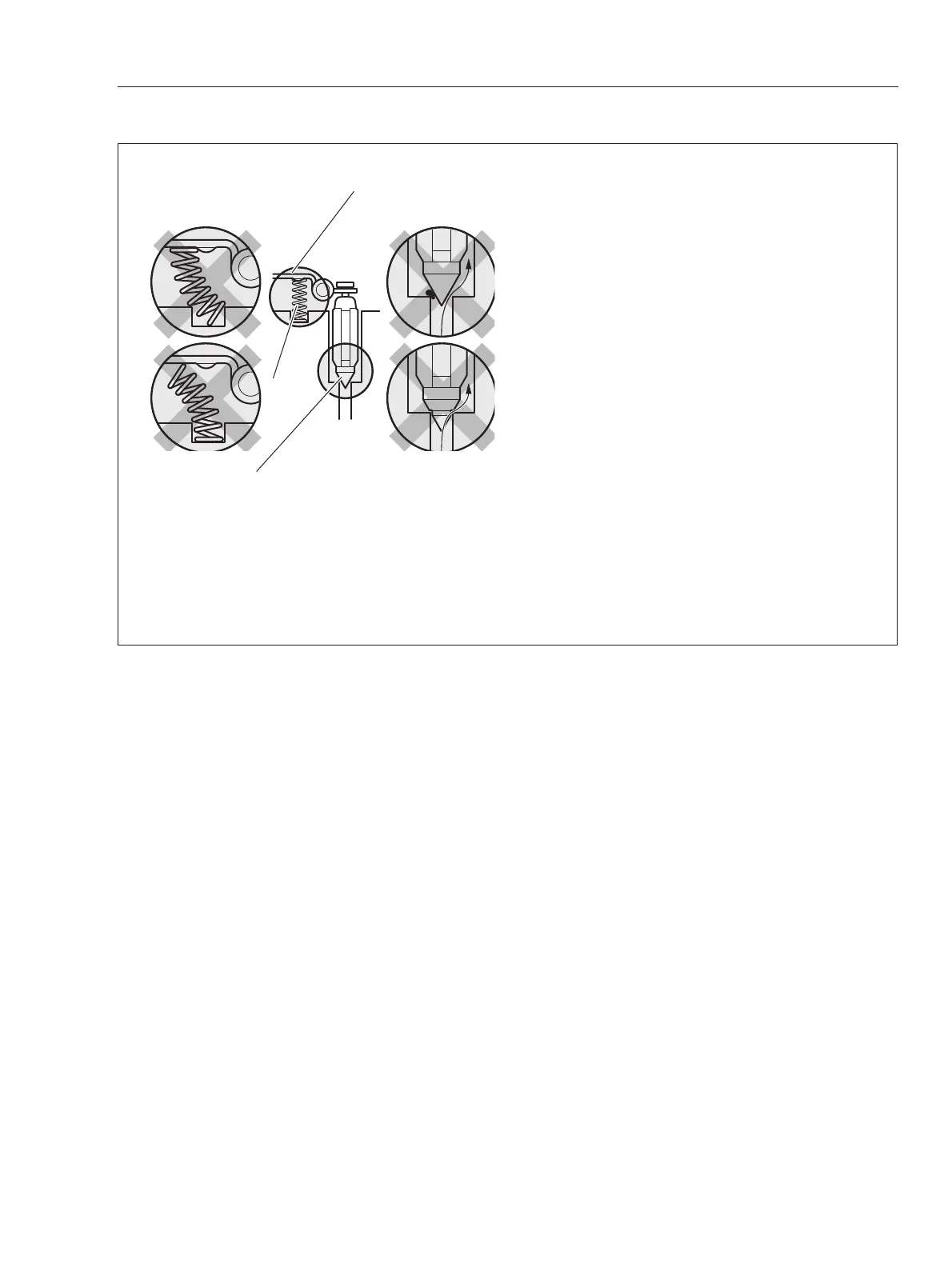

4-12 Inspecting inlet needle valve

1. Remove metering lever (A) and pivot pin. Re-

move spring (B) and inlet needle valve (C).

2. Inspect inlet needle valve if worn or sticky. Clean

or replace as required.

NOTE: Causes of fuel ooding from carburetor to

cylinder are as follows:

- Improper assembling of metering lever and

spring.

- Dirt between inlet needle valve and valve seat.

- Worn inlet needle valve tip.

3. Clean inlet needle valve seat using suitable

clean solvent (do not use metal tools).

4. Reassemble inlet needle valve (C), spring (B),

metering lever (A) and pivot pin.

NOTE: Insure proper metering lever installation as

follows.

(1) Spring is seated in its hole at chamber oor.

(2) Spring is under dimple of metering lever.

(3) Metering lever fork is holding inlet needle valve.

A

B

C

Loading...

Loading...