SERVICE INFORMATION

CS-2511TES

251Ts, 251TCs

3

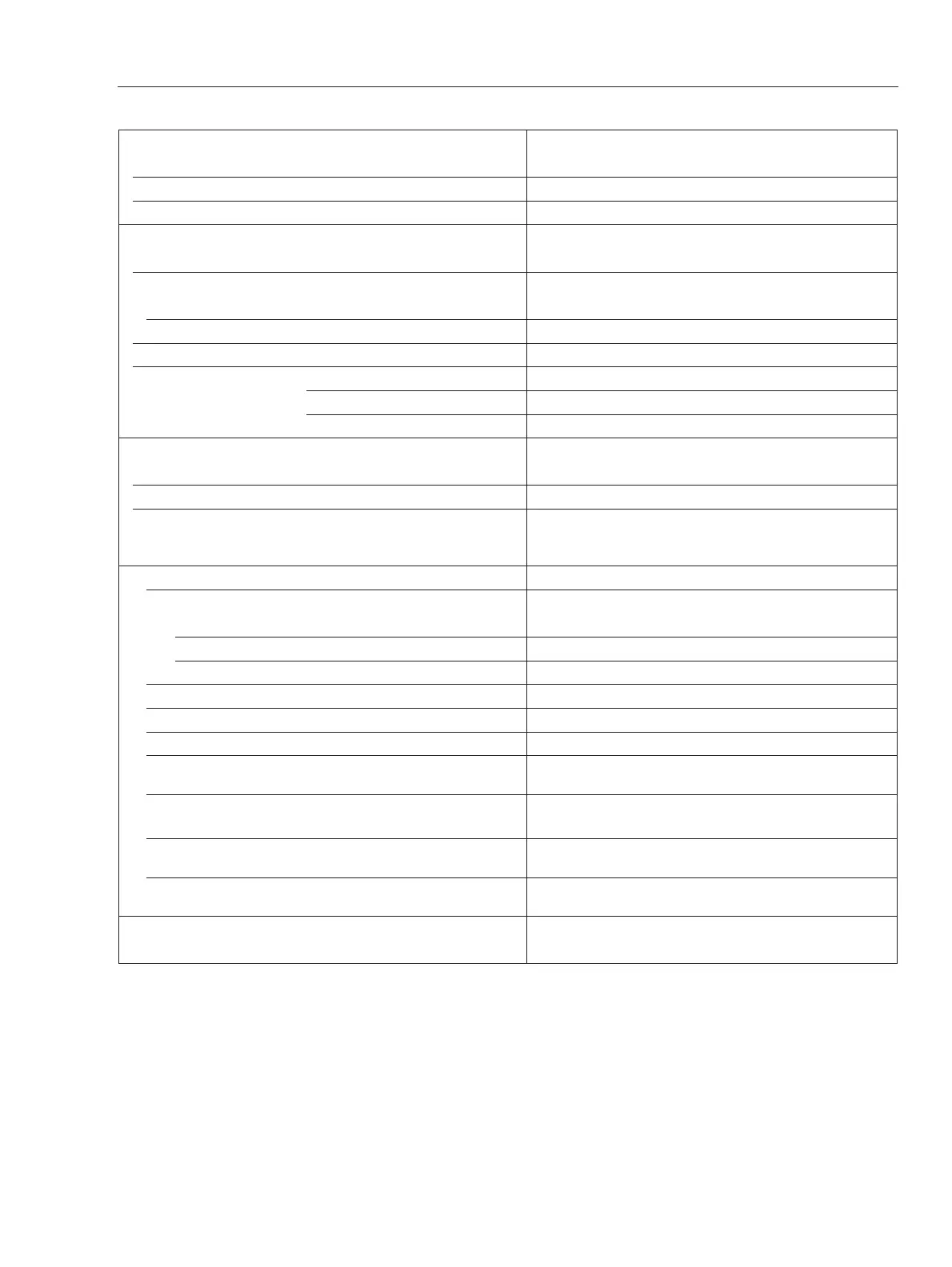

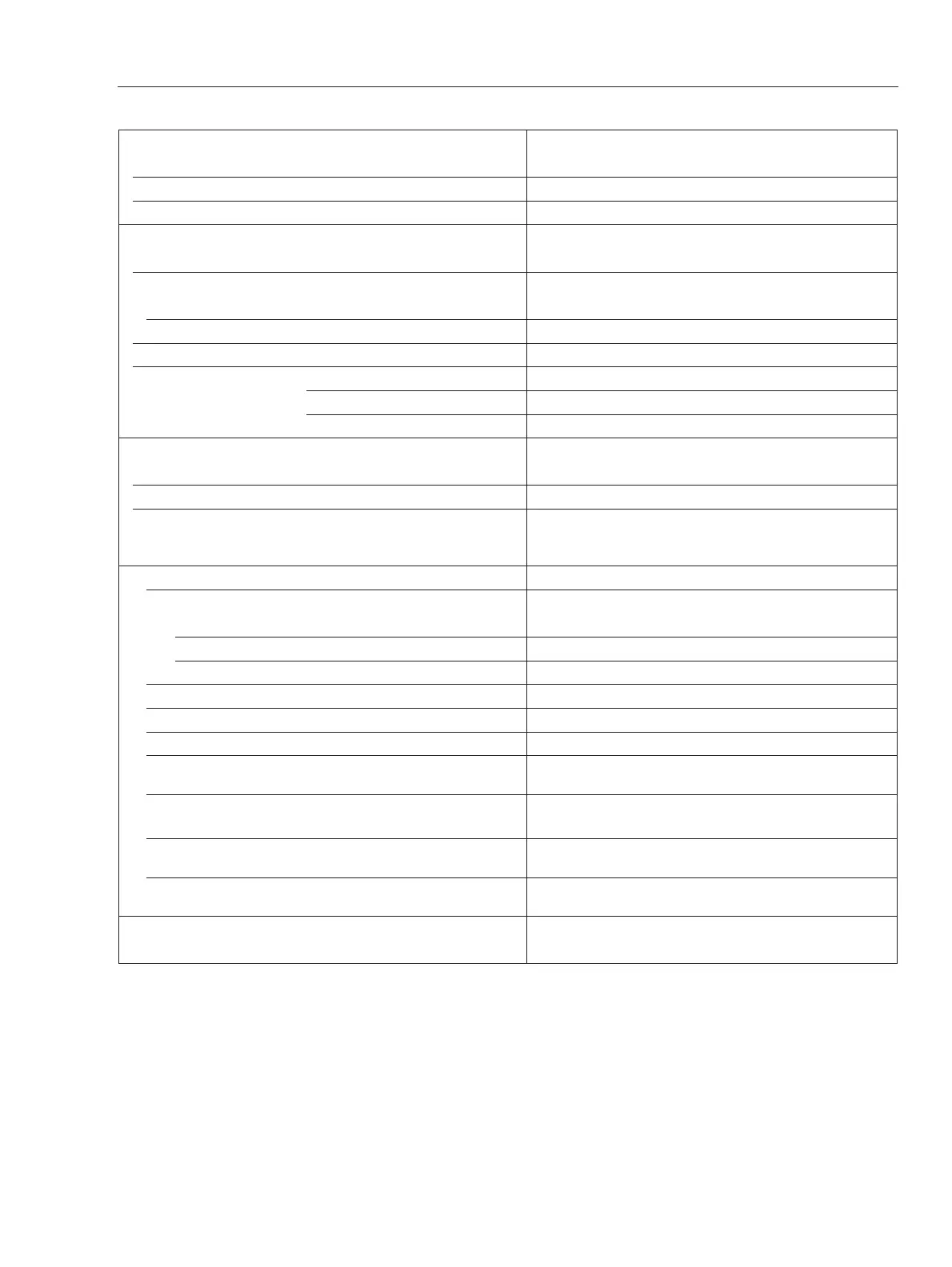

1-2 Technical data

Engine

Compression pressure MPa (kgf/cm

2

) (psi) 1.03 (10.5) (150)

Clutch engagement speed r/min 4,400

Engagement Minimum

†

r/min 3,900

Ignition system

Spark plug gap mm(in) 0.6 - 0.7 (0.024 - 0.028)

Spark test

Tester gap w/ spark plug mm(in) 4.0 (0.16)

Tester gap w/o spark plug mm(in) 6.0 (0.24)

Pole shoe air gaps mm(in) 0.3 - 0.4 (0.012 - 0.016)

Ignition timing at 1,000 r/min °BTDC

9

at 3,000 r/min °BTDC 12

at 10,000 r/min °BTDC 29

Carburettor

Test Pressure, minimum MPa (kgf/cm

2

) (psi) 0.05 (0.5) (7.0)

Metering lever height mm(in) 1.65 (0.06) lower than diaphragm seat

Tool to adjust mixture needles

Screwdriver 2.5 mm P/N X603-000050

D-shaped tool (L) P/N X645-000031

(Carb. adjustment tool P/N Y089-000094)

Carburettor adjustment

1) Initial setting

H mixture needle turn out

2 5/8

L mixture needle turn out 1 7/8

Throttle adjust screw turn in*

1

1 5/8

Engine warm-up Idle - WOT : Total sec. 5 - 5 : 100

2) Find idle maximum speed Adjust L mixture needle to maximum idle speed*

2

3) Set idle maximum speed w/ TAS r/min 4,000

4) Set idle speed

by turning L mixture needle ACW

r/min 3,200 (2,800 - 3,600)

5) Conrm H mixture needle position

before WOT setting

*

3

Turn H mixture needle ACW to conrm engine

speed decreses less than 12,000 r/min

6) WOT setting

Turn H mixture needle CW and set engine speed

within 12,400 - 12,600 r/min

7) Final WOT setting

Turn H mixture needle CW by : 1/4

within 1

2,700 - 13,400

r/min

Chain oil discharge volume

Adjustable: 1.5 - 13 (0.05 - 0.46)

(Factory set: 7 mL/min)

mL/min(UK..oz./min)

BTDC: Before top dead centre. WOT: Wide open throttle ACW: Anticlockwise TAS: Throttle adjust screw

†

If clutch engagement speed is lower than minimum clutch engagement speed, replace clutch assembly with

new one.

*

1

Set Throttle adjust screw to the point that its tip just contacts throttle plate before initial setting.

*

2

If clutch engages during adjustment process 2), decrease engine speed by turning TAS ACW until clutch

disengages and then redo 2).

*

3

With 25 cm guide bar and properly tensioned saw chain.

Loading...

Loading...