STP-301/451 Series Instruction Manual

4-9

Installation

1) When securing the inlet port with bolts

Refer to Table 4.2 for torque in pump abnormality and recommended securing bolts.

Secure the inlet port flange with all of the boltholes of the size specified in the Inlet

Port Flange Standard.

Secure the base with all 8 screw-holes for legs or all 8 attached legs.

Follow "CAUTION" on page 4-8 about legs and bolts for securing the base. Make

sure that the recommended securing bolt may be different depending on the method

of securing the base.

Table 4.2 Maximum Torque predicted and Recommended securing bolt

for inlet port flange

Model of TMP STP-301

Type of flange VG100 ISO100F

*1

ICF152

Torque in pump abnormality [Nm] 3.8×10

3

3.8×10

3

3.8×10

3

Base(8 positions)securing No Yes No Yes No Yes

Type of bolt Standard

Type of steel

*2

Stainless steel

Recommended

securing bolt for TMP

Flange

Strength

*2

70 or more

Model of TMP STP-451

Type of flange VG150 ISO160F

*1

ICF203

Torque in pump abnormality [Nm] 3.8×10

3

3.8×10

3

3.8×10

3

Base(8 positions)securing No Yes No Yes No Yes

Type of bolt Standard

Type of steel

*2

Stainless steel

Recommended

securing bolt for TMP

Flange

Strength

*2

70 or more

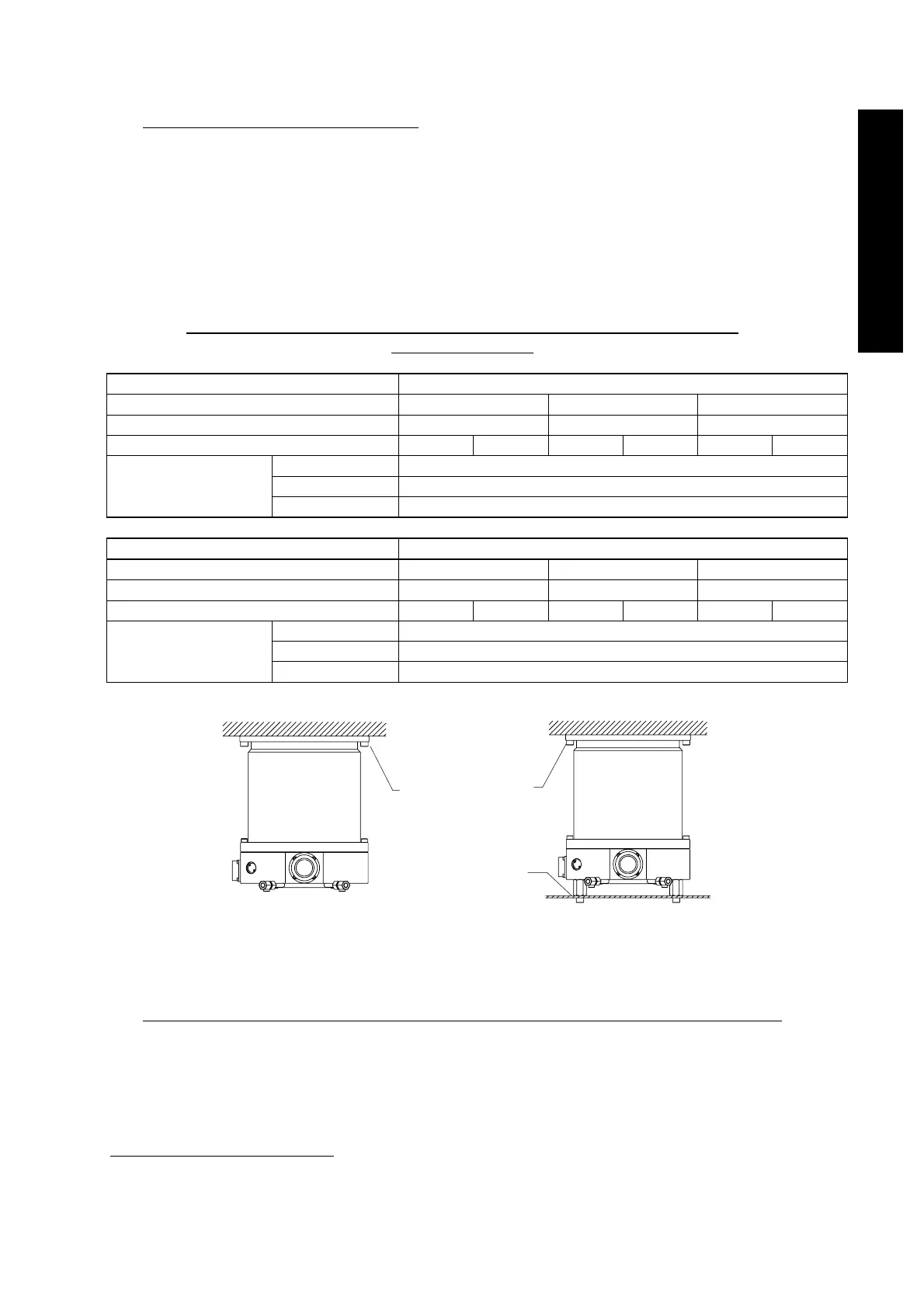

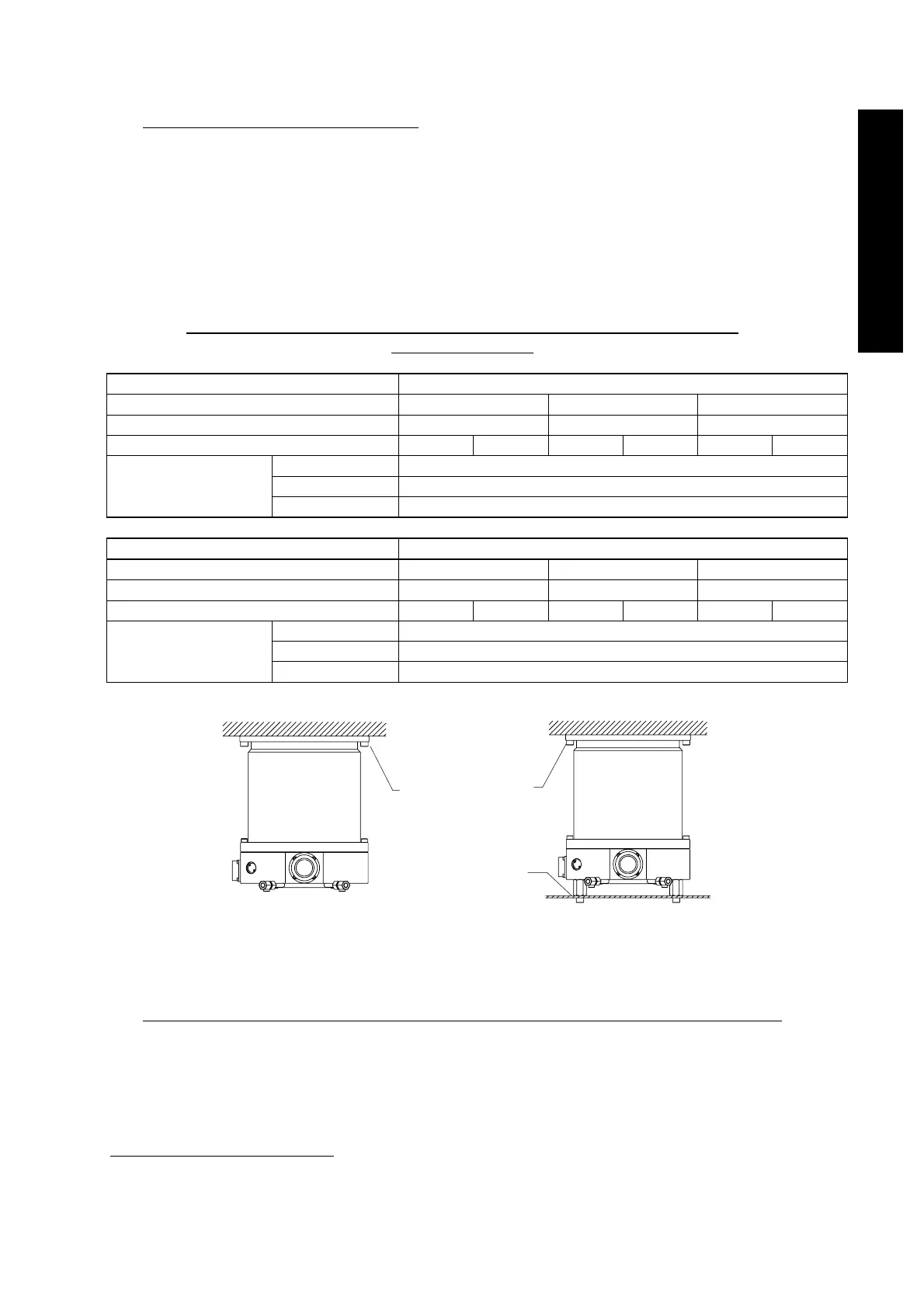

(a) When the base is not secured (b) When the base is secured

Figure 4.5 Example of securing the STP Pump (When securing the inlet port with bolts)

*1

Maximum predicted torque of ISO flange type pump is the same as that of ISO_F flange type pump.

*2

Refer to ISO898-1 (JISB1051), ISO3506 (JISB1054) and AMS6419 (Aerospace Material Specification)

Recommended

fitting bolt for flange

Secure the base

Loading...

Loading...