Cerabar M, Deltabar M, Deltapilot M Installation

Endress+Hauser 23

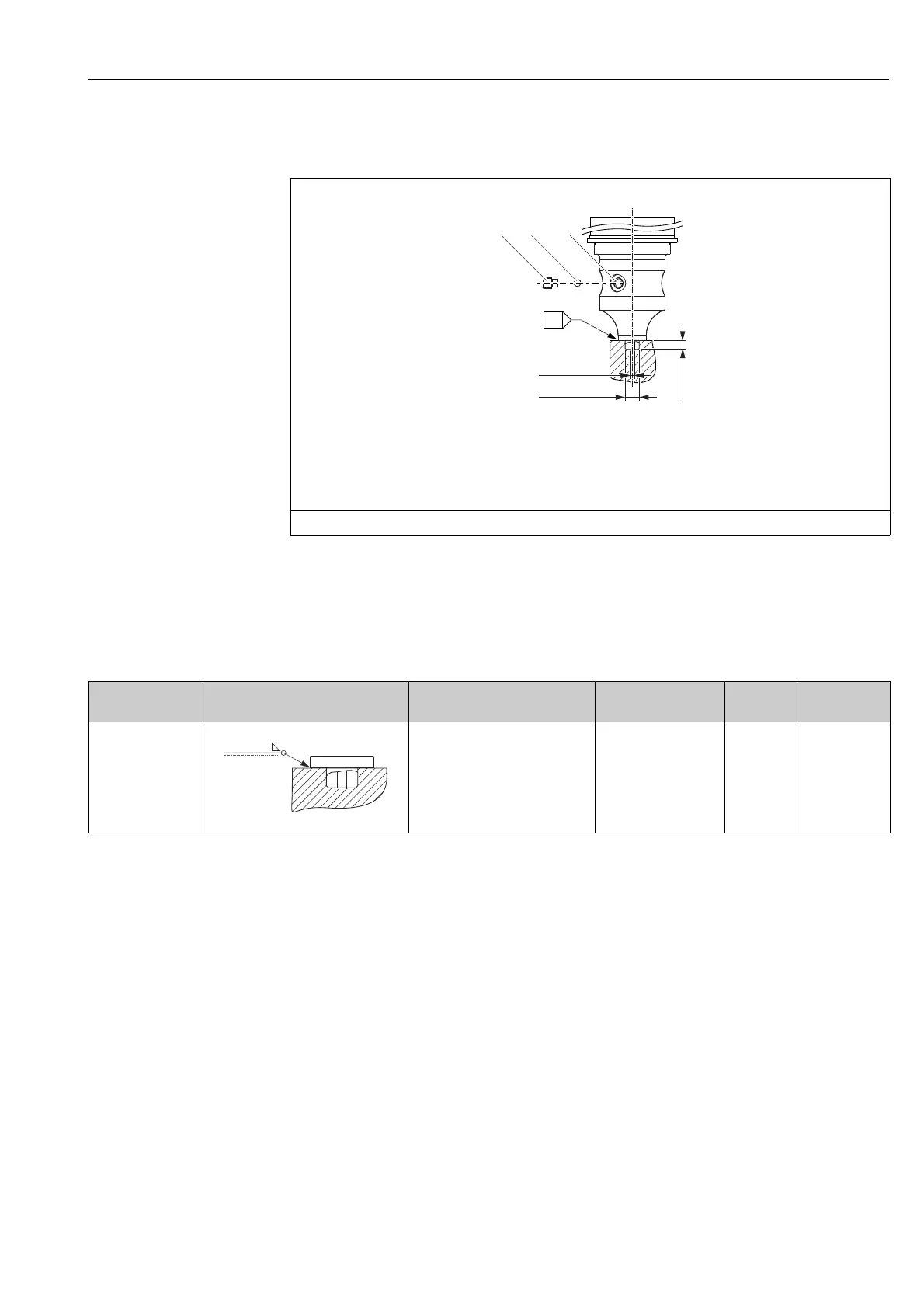

4.5.7 PMP51, version prepared for diaphragm seal mount –

welding recommendation

Endress+Hauser recommends welding on the diaphragm seal as follows for the "XSJ -

prepared for diaphragm seal mount" version in feature 110 "Process connection" in the order

code up to, and including, 40 bar (600 psi) sensors: the total welding depth of the fillet weld

is 1 mm (0.04 in) with an outer diameter of 16 mm (0.63 in). Welding is performed

according to the WIG method.

Information on filling

The diaphragm seal must be filled as soon as it has been welded on.

• After welded into the process connection, the sensor assembly must be properly filled with

a filling oil and sealed gas-tight with a sealing ball and lock screw.

Once the diaphragm seal has been filled, at the zero point the device display should not

exceed 10% of the full scale value of the cell measuring range. The internal pressure of the

diaphragm seal must be corrected accordingly.

• Adjustment / calibration:

– The device is operational once it has been fully assembled.

– Perform a reset. The device must then be calibrated to the process measuring range as

described in the Operating Instructions.

A0028495

Fig. 15: Version XSJ: prepared for diaphragm seal mount

1 Hole for fill fluid

2Bearing

3Setscrew

A1 See the "Welding recommendation" table below

Engineering unit mm (in)

A1

ø7.95 (0.31)

ø2.5 (0.1)

5 (0.2)

12 3

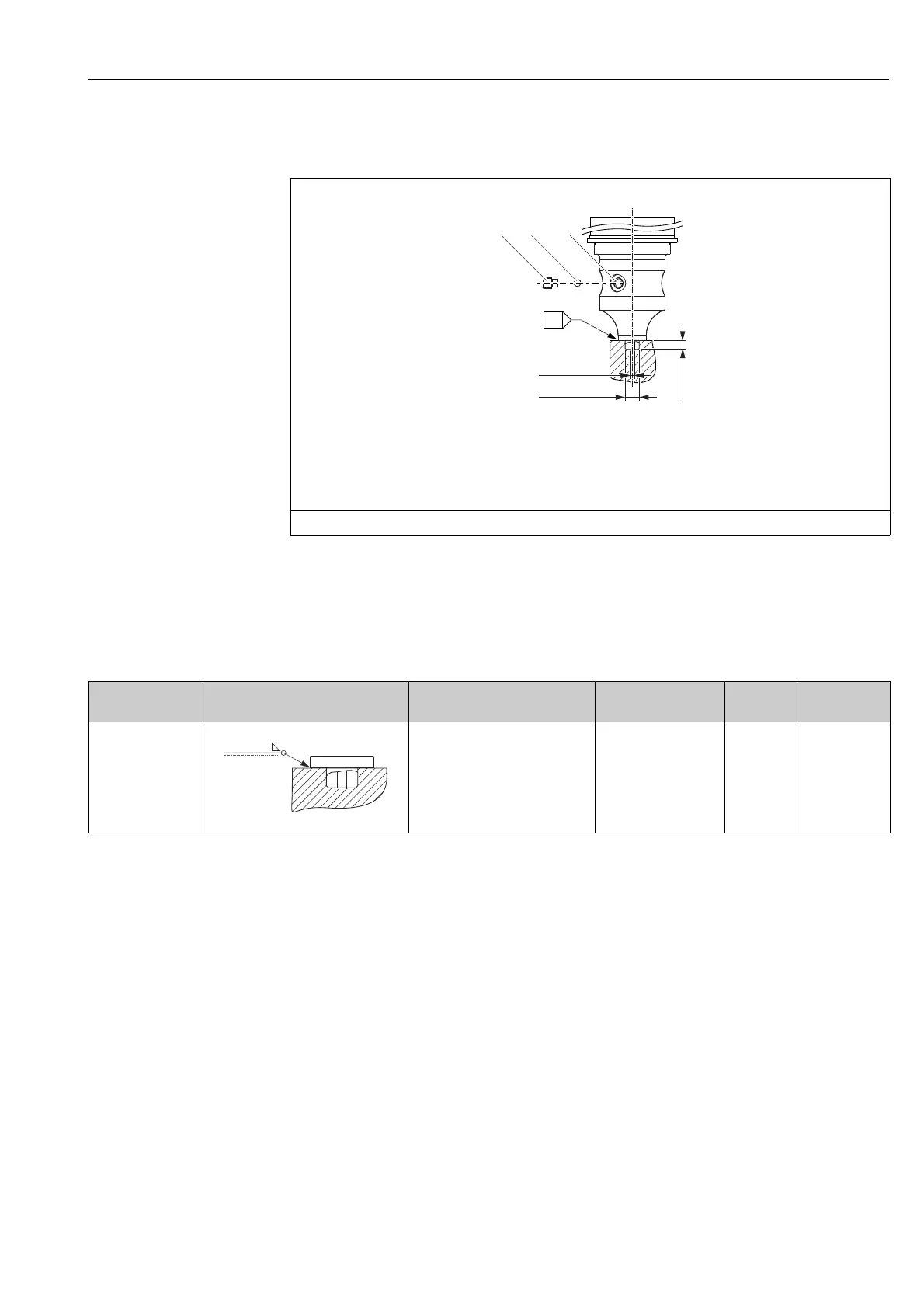

Consecutive seam

no.

Sketch/welding groove shape,

dimension as per DIN 8551

Base material matching Welding method

DIN EN ISO 24063

Welding

position

Inert gas,

additives

A1

for sensors

40 bar (600 psi)

A0024811

Adapter made of AISI 316L

(1.4435) to be welded to

diaphragm seal made of

AISI 316L (1.4435 or 1.4404)

141 PB Inert gas

Ar/H 95/5

Additive:

ER 316L Si

(1.4430)

Loading...

Loading...