Cerabar M, Deltabar M, Deltapilot M Commissioning with the FF configuration program

Endress+Hauser 161

9.10 Electrical differential pressure measurement with

gauge pressure sensors (Cerabar M or Deltapilot M)

Example:

In the example given, two Cerabar M or Deltapilot M devices (each with a gauge pressure

sensor) are interconnected. The pressure difference can thus be measured using two

independent Cerabar M or Deltapilot M devices.

For a description of the parameters mentioned Chap. 8.11 "Description of parameters".

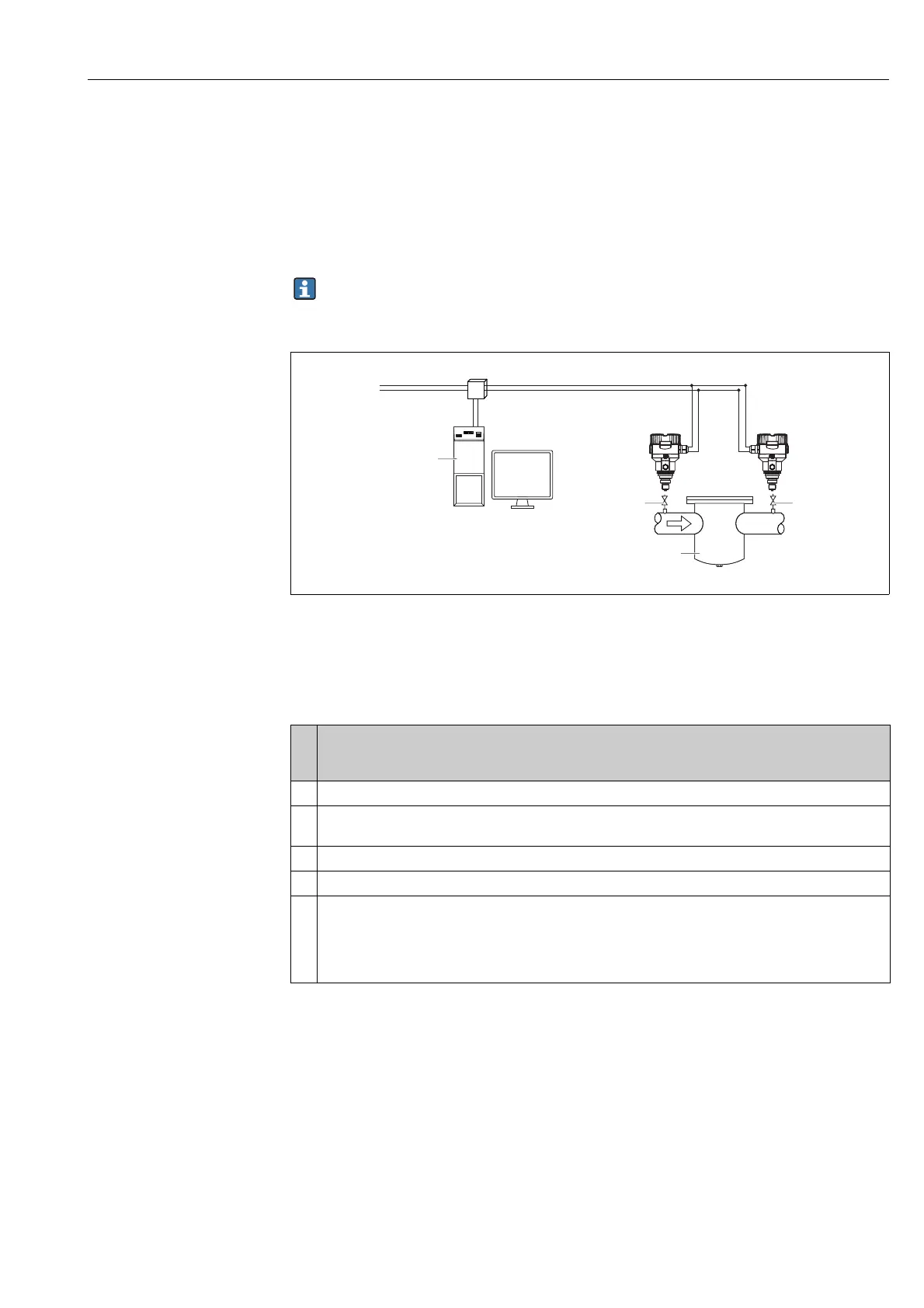

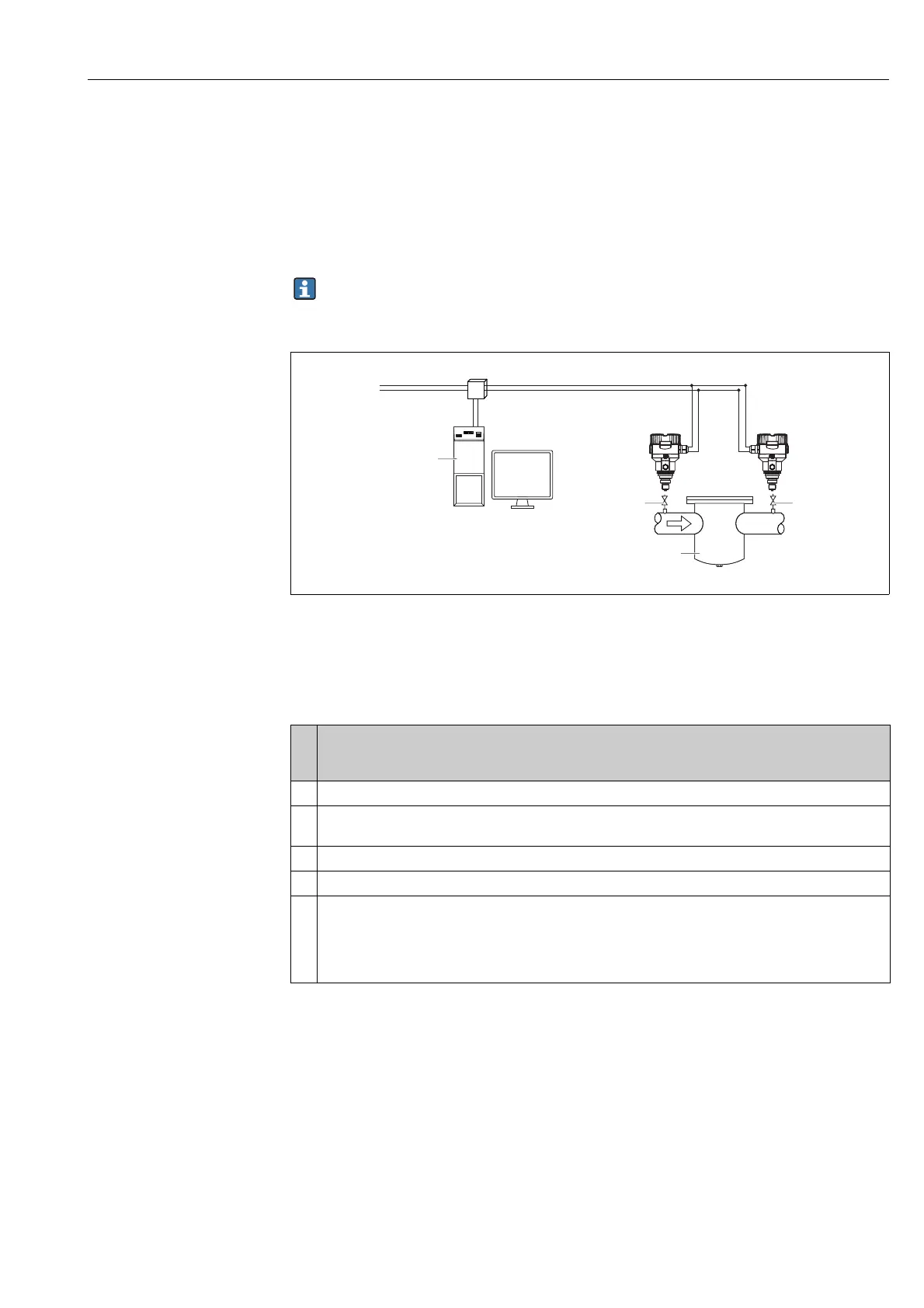

A0030415

Fig. 49:

1 Shut-off valves

2 e.g. filter

3 FF HOST System

1.)

2.)

The Analog Input Block output of the high-pressure side of the device has to be connected

to one of the 4 inputs of the Input Selector Block on the low-pressure side of the device (here

Input1 for example).

This configuration has to be written to the devices.

Both blocks must be set to the Auto mode.

Description

Adjustment of the Cerabar M/Deltapilot M on the high-pressure side in the Pressure Transducer

Block

1 Open the Pressure Transducer Block and set the block mode to OOS.

2 Select the "Pressure" measuring mode via the Measuring mode/OPERATING_MODE or Primary Value Type/

PRIMARY_VALUE_TYPE parameter.

3 Select a pressure unit via the Calibration Units/CAL_UNIT parameter, here "mbar" for example.

4 The Cerabar M/Deltapilot M is unpressurized, perform position adjustment, see ä 73.

5 Set the Pressure Transducer Block to the "Auto" block mode. If necessary, configure the

Channel/CHANNEL ( ä 211),

Linearization Type/L_TYPE ( ä 212),

Transducer Scale/XD_SCALE ( ä 210) and

Output Scale/OUT_SCALE ( ä 211) parameters by means of the Analog Input Block.

Loading...

Loading...