Installation Cerabar M, Deltabar M, Deltapilot M

14 Endress+Hauser

4.5 Installing Cerabar M

• Due to the orientation of the Cerabar M, there may be a shift in the zero point, i.e. when

the container is empty or partially full, the measured value does not display zero. You can

correct this zero point shift ä 47, Section "Function of the operating elements" or

ä 73, Section 8.3 "Pos. zero adjust".

• For PMP55, please refer to Section 4.5.2 "Installation instructions for devices with

diaphragm seals – PMP55", ä 17.

• Endress+Hauser offers a mounting bracket for installing on pipes or walls.

ä 21, Section 4.5.5 "Wall and pipe mounting (optional)".

4.5.1 Installation instructions for devices without diaphragm seals –

PMP51, PMC51

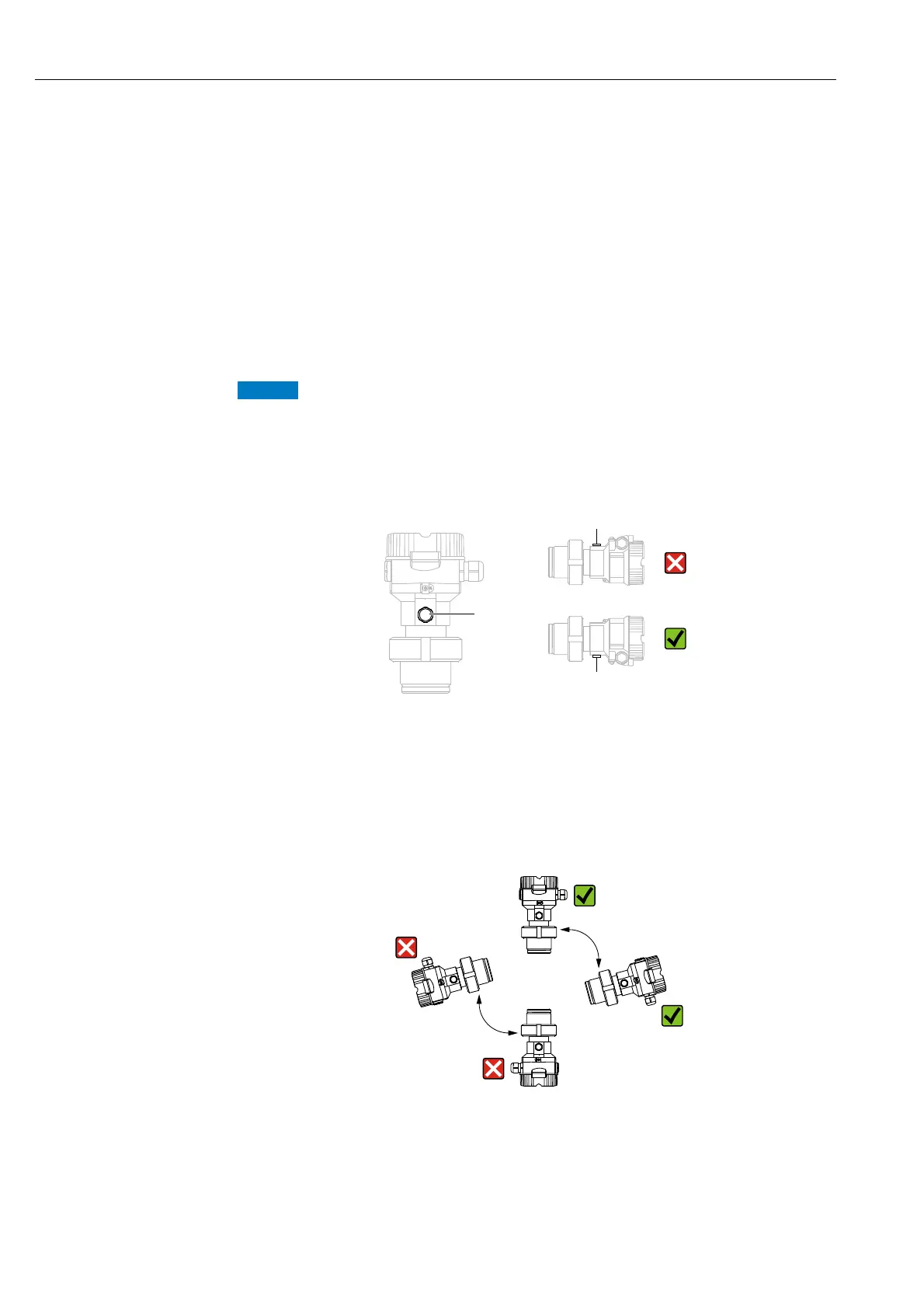

Damage to the device!

If a heated Cerabar M is cooled during the cleaning process (e.g. by cold water), a vacuum

develops for a short time, whereby moisture can penetrate the sensor through the pressure

compensation (1).

‣ If this is the case, mount the Cerabar M with the pressure compensation (1) pointing

downwards.

• Keep the pressure compensation and GORE-TEX

®

filter (1) free from contamination.

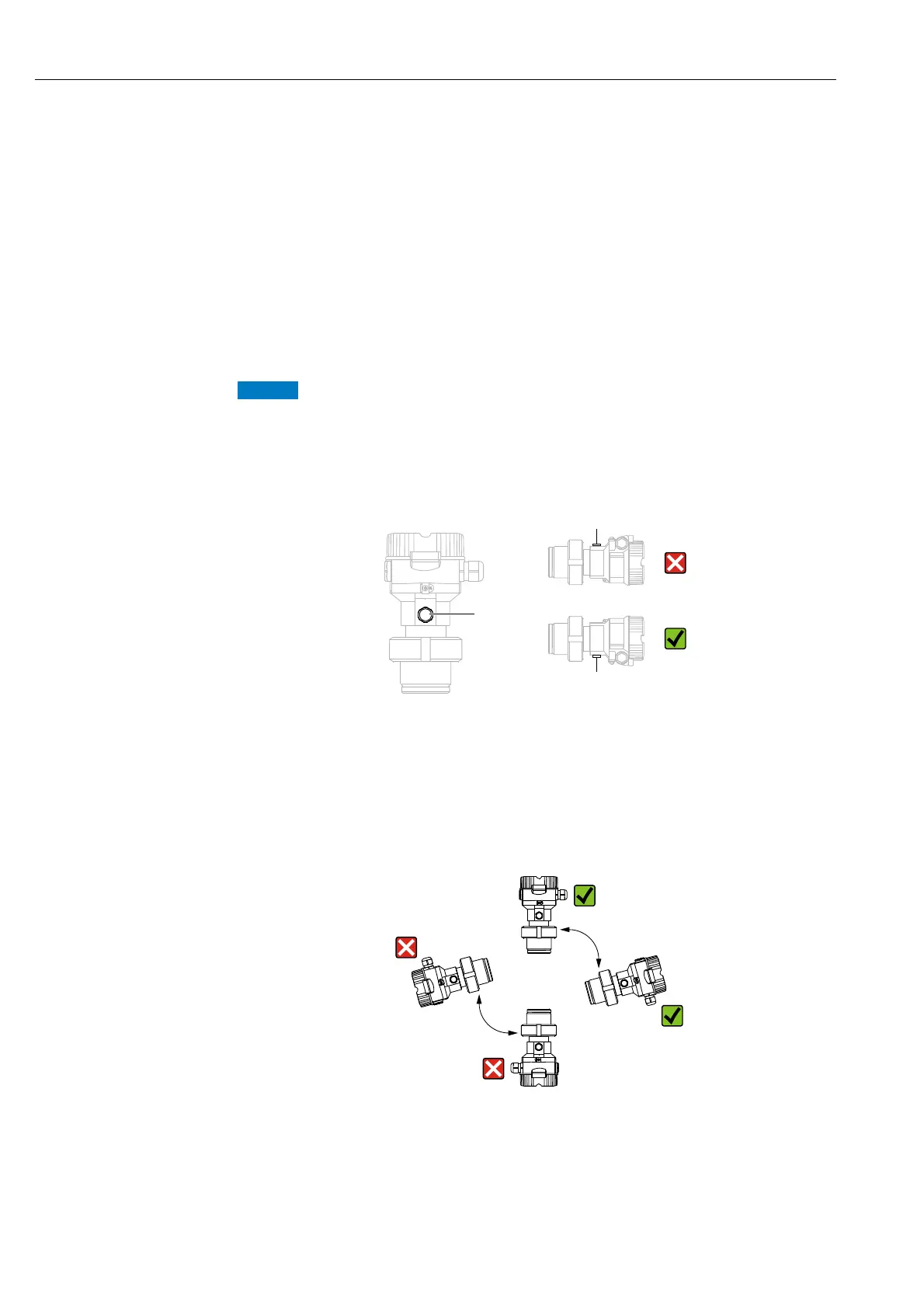

• Cerabar M transmitters without diaphragm seals are mounted as per the norms for a

manometer (DIN EN 837-2). We recommend the use of shutoff devices and siphons. The

orientation depends on the measuring application.

• Do not clean or touch process isolating diaphragms with hard or pointed objects.

• The device must be installed as follows in order to comply with the cleanability

requirements of the ASME-BPE (Part SD Cleanability):

Loading...

Loading...