Commissioning with an operating menu (onsite display/FieldCare) Cerabar M, Deltabar M, Deltapilot M

98 Endress+Hauser

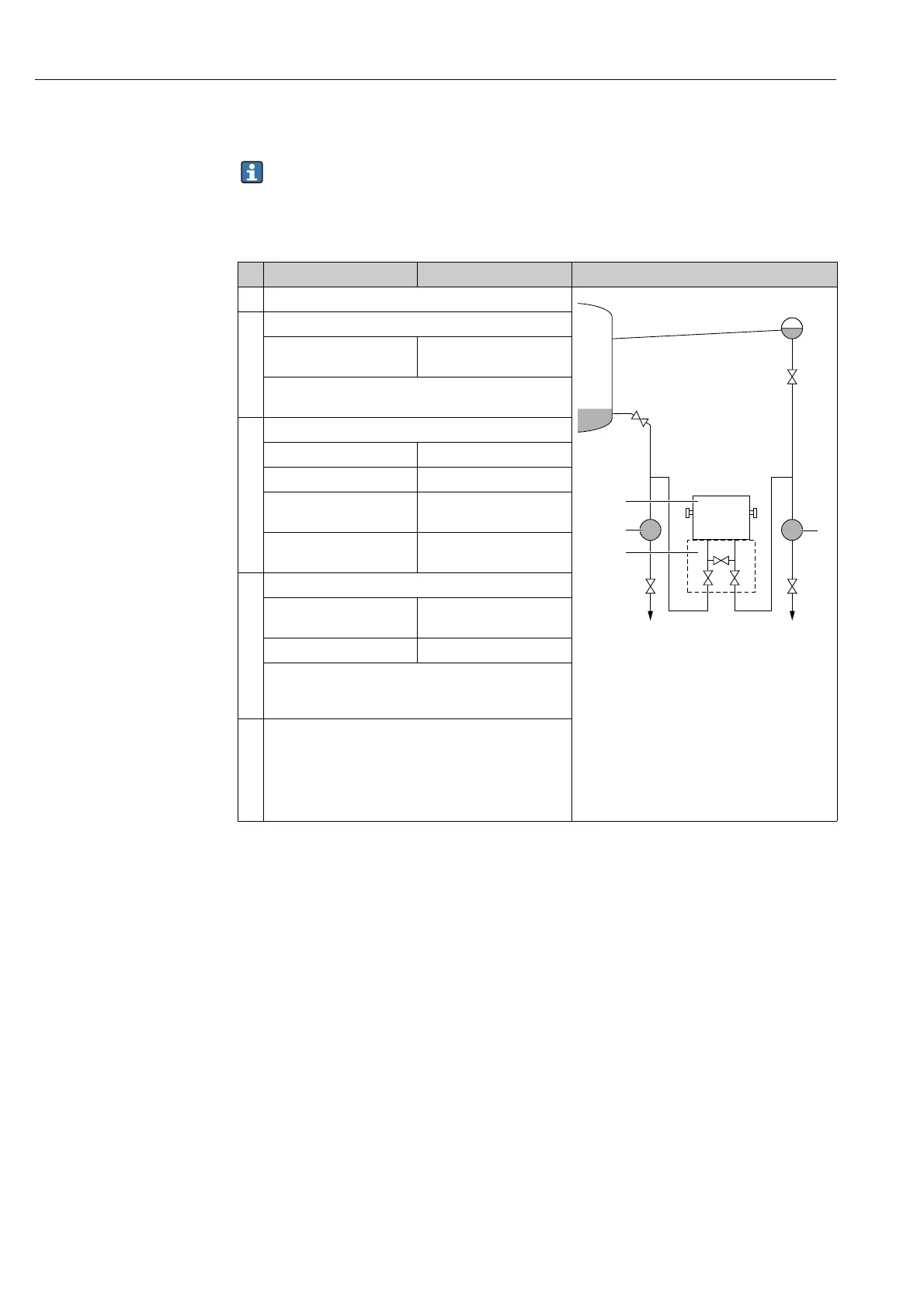

Closed container with superimposed steam

Before calibrating the device, the impulse piping must be cleaned and filled with medium.

See the following table.

Valves Meaning Installation

1 Fill container to a level above the lower tap.

A0030040

Closed container with superimposed steam

I Deltabar M

II Three-valve manifold

III Separator

1, 5 Drain valves

2, 4 Inlet valves

3 Equalizing valve

6, 7 Vent valves on Deltabar M

A, B Shut-off valves

2 Fill measuring system with medium.

Open A and B. Open shut-off valves.

Fill the negative impulse piping to the level of the

condensate trap.

3Vent device.

Open 2 and 4. Introduce medium.

Close 4. Close low-pressure side.

Open 3. Balance positive and low-

pressure side.

Open 6 and 7 briefly, then

close them again.

Fill device completely with

medium and remove air.

4 Set measuring point in operation.

Close 3. Shut off high-pressure side

from low-pressure side.

Open 4. Connect low-pressure side.

Now

– 3, 6 and 7 are closed.

– 2, 4, A and B are open.

5 Carry out calibration according to one of the following

methods:

• "In pressure" - with reference pressure ( ä 99)

• "In pressure" - without reference pressure ( ä 101)

• "In height" - with reference pressure ( ä 103)

• "In height" - without reference pressure ( ä 105)

A

II

III

III

–

P2

+

P1

6

7

3

24

I

15

+

–

B

Loading...

Loading...