Deltabar PMD75B PROFINET with Ethernet-APL Commissioning

Endress+Hauser 51

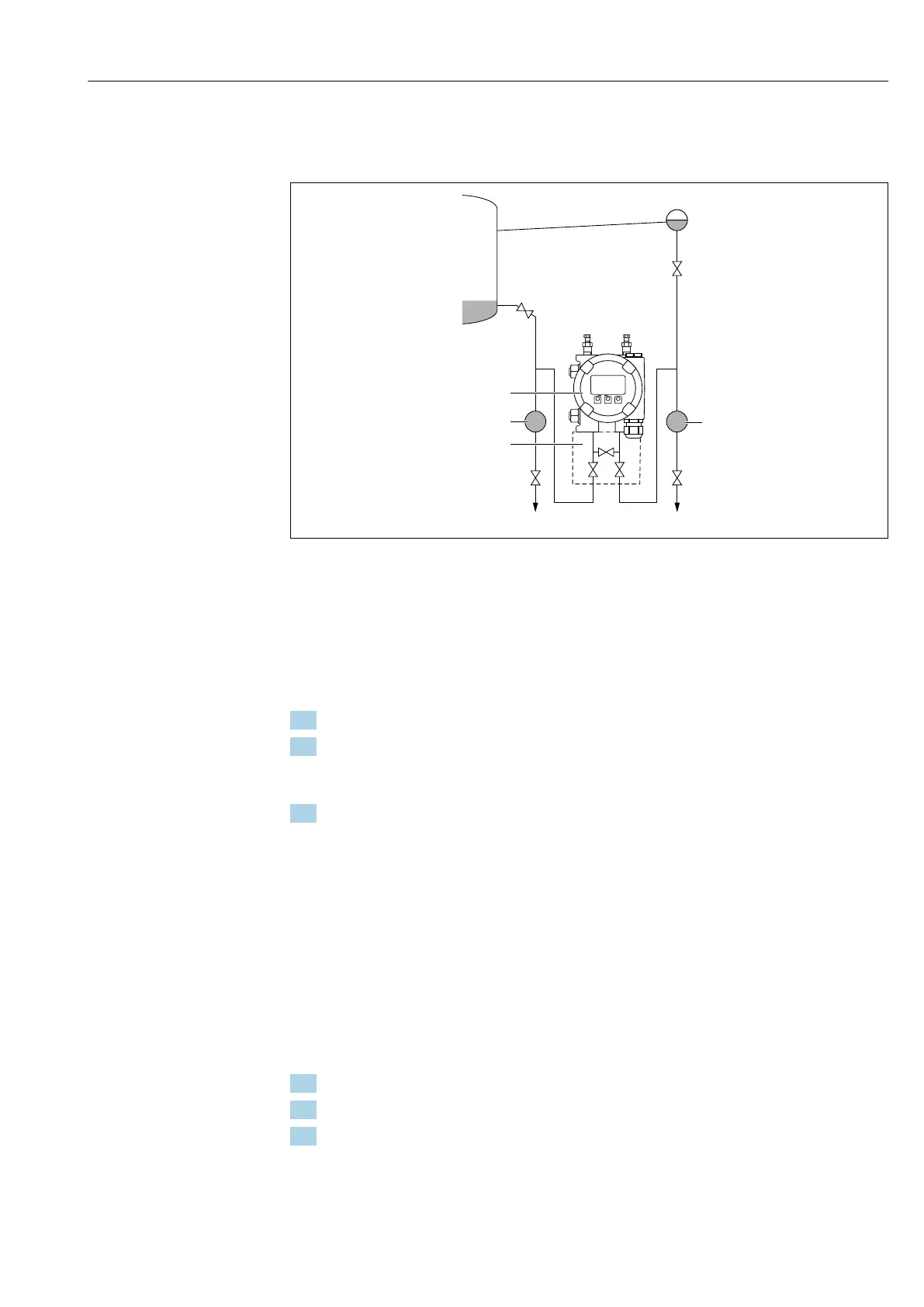

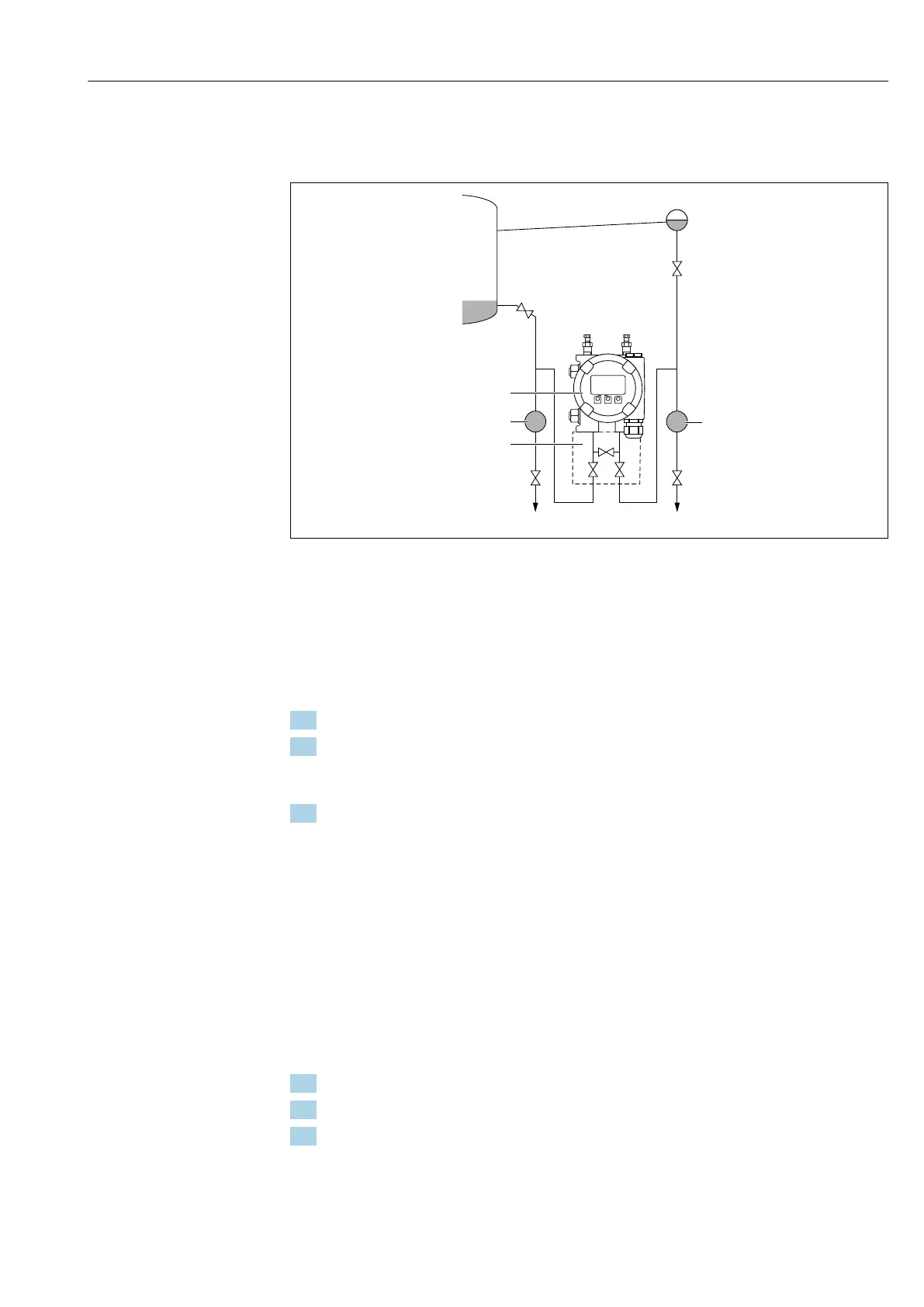

Closed vessel with superimposed vapor

Before adjusting the device, the piping may need to be cleaned and filled with medium.

A

II

I II

I II

–

P2

+

P1

6

7

3

2 4

I

1 5

+

–

B

ESC

-

+ E

A0030040

I Device

II Three-valve manifold

III Separator

1, 5 Drain valves

2, 4 Inlet valves

3 Equalization valve

6, 7 Vent valves on device

A, B Shutoff valves

1. Fill the vessel to above the lower tapping point.

2. Fill the measuring system with medium.

Open A and B (shutoff valves).

Fill the negative pressure piping to the height of the condensate trap.

3. Vent device.

Open 2 and 4 (introduce fluid).

Open 6 and 7 until the system (piping, valve and side flange) is completely filled

with medium.

9.7.3 Commissioning with keys on the electronic insert

The following functions are possible via the keys on the electronic insert:

• Position adjustment (zero point correction)

The orientation of the device may cause a pressure shift

This pressure shift can be corrected by a position adjustment

• Resetting the device

Carrying out position adjustment

1. Device installed in desired position and no pressure applied.

2. Press the "Zero" key for at least 3 s.

3. When the LED flashes twice, the pressure present has been accepted for position

adjustment.

Resetting the device

‣

Press and hold the "Zero" key for at least 12 seconds.

Loading...

Loading...