Deltabar S

Endress+Hauser 21

Operating conditions (installation)

General installation instructions • For FMD 77 and FMD 78: See page 50 ff, "Installation instructions, Diaphragm seal systems" section.

• The position-dependent zero shift can be corrected directly at the device via operating keys, even in

hazardous areas. Diaphragm seals also shift the zero point, depending on the installation position (→ See also

page 50 ff, "Installation instructions, Diaphragm seal systems").

• The housing of the Deltabar S can be rotated up to 380°. → See also page 22, section "Rotating the

housing".

• Endress+Hauser offers a mounting bracket for installing on pipes or walls. → See also page 22, section

"Wall- and pipe-mounting".

• When measuring in media with solid proportions, such as dirty liquids, installing separators and drain valves

is useful for capturing and removing sediment.

• Using a three-valve or five-valve manifold allows for easy commissioning, installation and maintenance

without interrupting the process.

• General recommendations for the impulse piping can be found in DIN 19210 "Methods for measurement of

fluid flow; differential piping for flow measurement devices" or the corresponding national or international

standards.

• Install the impulse piping with a continuous gradient of at least 10%.

• When routing the impulse piping outdoors, ensure that sufficient anti-freeze protection is used, e.g. by using

pipe heat tracing.

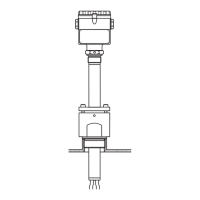

Measuring arrangement Flow measurement

• The PMD 70 and PMD 75 are best suited to flow measurement.

• Measuring arrangement for gases: Mount device above the measuring point.

• Measuring arrangement for liquids and steam: Mount device below tapping point.

• For flow measurement in steam, mount the condensate traps at the same level as the tapping point and at

the same distance from Deltabar S.

Level measurement

• PMD 70, PMD 75, FMD 76 and FMD 77 are best suited to level measurement in open tanks. All Deltabar

S devices are suitable for level measurement in closed tanks.

Measuring arrangement level measurement in open tanks

• PMD 70, PMD 75: Mount device below the lower measuring connection. The negative side is open to

atmosphere pressure.

• FMD 76, FMD 77: Mount device directly on the tank or with shut-off valve. The negative side is open to

atmospheric pressure.

Measuring arrangement level measurement in closed tanks and closed tanks with static pressure

• PMD 70, PMD 75: Mount device below the lower measuring connection. Always connect the negative side

above the maximum level.

• FMD 76, FMD 77: Mount device directy on the tank. Always connect the negative side above the maximum

level.

• In the case of level measurement in closed tanks with static pressure, a condensate trap ensures pressure

which remains constant on the minus side.

Pressure measurement

• The PMD 70 and PMD 75 are best suited to differential pressure measurement.

• Measuring arrangement for gases: Mount device above the measuring point.

• Measuring arrangement for liquids and steam: Mount device below tapping point.

• For differential pressure measurement in steam, mount the condensate traps at the same level as the tapping

point and at the same distance from Deltabar S.

Loading...

Loading...