Deltabar S

Endress+Hauser 45

Planning instructions, diaphragm seal systems

Applications Diaphragm seal systems should be used if the process media and the device should be separated. Diaphragm

seal systems offer clear advantages in the following instances:

• In the case of high process temperatures (→ See also page 24, section "Process temperature limits".)

• In the case of process media that crystallize

• In the case of corrosive process media or process media with solids content

• In the case of heterogeneous and fibrous process media

• If measuring point cleaning is necessary

• The measuring point is exposed to vibration.

• Installation sites that are difficult to access (e.g. better view of display).

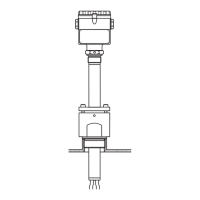

Design and operation mode Diaphragm seals separate the measuring system and the process medium.

A diaphragm seal system consists of:

• A diaphragm seal in a one-sided system, e.g. FMD 77 or two diaphragm seals, in a two-sided system, e.g.

FMD 78

• Capillary tube

• Fill fluid and

• A differential pressure transmitter.

The process pressure acts via the diaphragm seal membrane on the liquid-filled system, which transfers the

process pressure via the capillary tube onto the sensor of the differential pressure transmitter.

Endress+Hauser delivers all diaphragm seal systems as welded versions. The system is hermetically sealed,

which ensures the highest reliability.

Note!

The correlations between the individual diaphragm seal components are presented in the following section.

For further information and comprehensive diaphragm seal system designs, please contact Endress+Hauser

Sales.

Diaphragm seal

The diaphragm seal determines the application range of the system by

• the diaphragm diameter

• the diaphragm: stiffness and materials of construction

• the design (oil volume).

Diaphragm diameter

The larger the diaphragm diameter (less stiffness), the smaller the temperature effect on the measurement

result.

Note: When feasible, select diaphragm seals with a nominal diameter of ≥ 3" (DN 80), to reduce temperature

effects within acceptable limits.

Diaphragm stiffness

The stiffness is dependent on the diaphragm diameter, the material, any available coating and on the diaphragm

thickness and shape. The diaphragm thickness and the shape are defined by the limits of the process connection

construction. The stiffness of a diaphragm seal membrane influences the temperature operating range and the

measuring error caused by temperature effects.

Capillary

Diaphragm seals are used with the following capillary internal diameters as standard:

• ≤ 2" (DN 50): 0.04" (1 mm)

• > 2" (DN 50): 0.08" (2 mm)

The capillary tube influences the T

K

zero point, the ambient temperature operating range and the response time

of a diaphragm seal system as a result of its length and internal diameter.

→ See also page 47 ff, sections "Influence of the temperature on the zero point for diaphragm seal

systems", "Ambient temperature range" and "Response time".

→ Observe the installation instructions regarding capillary tubes. See page 50 ff, section "Installation instruc-

tions".

Loading...

Loading...