Section 7: Using the Epilog Dashboard

112

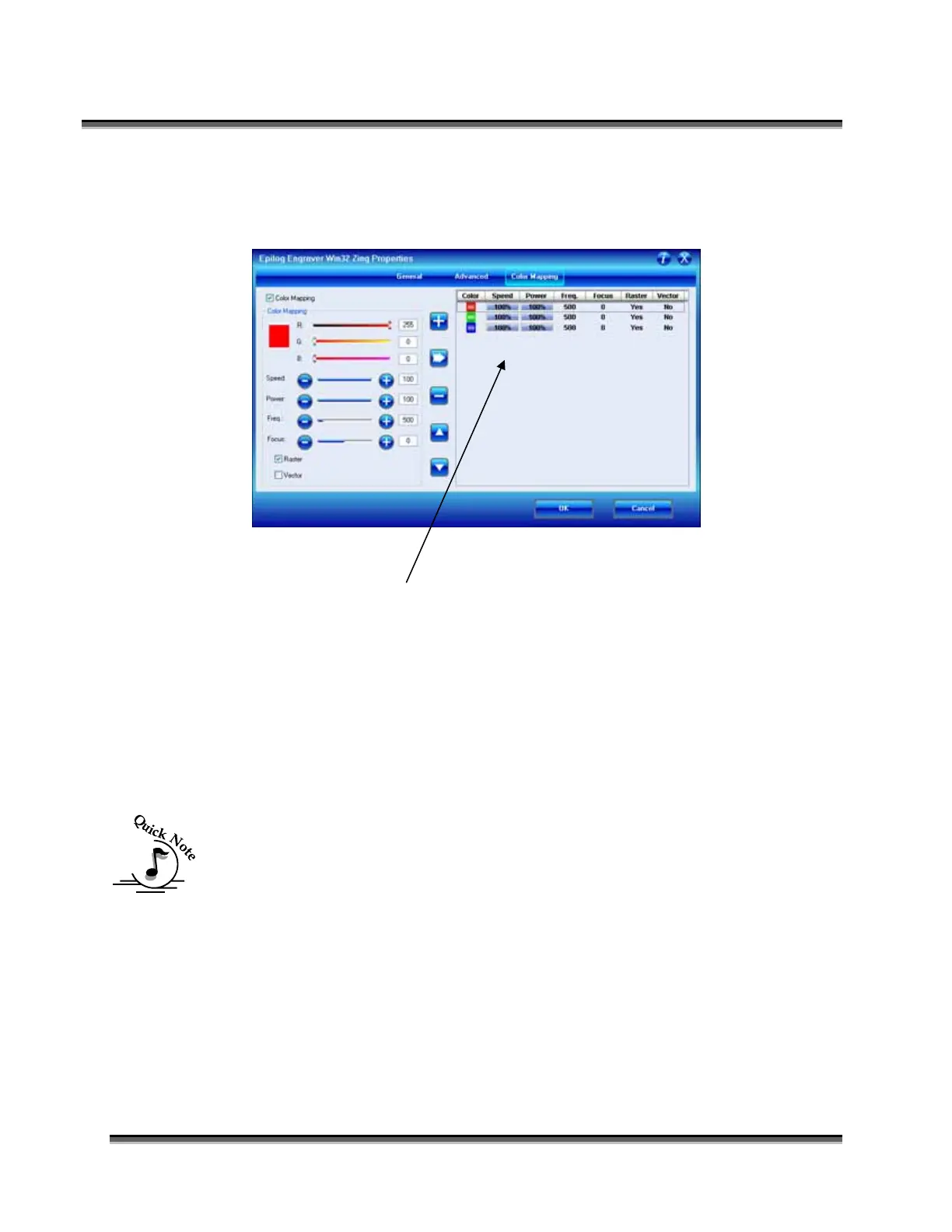

Dashboard you will follow the same process that was used in Vector Color

Mapping for setting up the Raster Color Mapping colors, but for this example we

will assign all colors the same speed and power (see following diagram).

We want all three of the pens to engrave at the same depth, so we have set all of

the Speed and Power settings the same (100% Speed and 100% Power). The

engraver will engrave the red column first, the green second and the blue third.

When you run this Raster Color Mapping job, the laser beam will be on most of

the time that the carriage is moving so the total amount of time to engrave the

pens will be decreased.

Color Mapping is most efficient as a time saver whenever there is a large amount

of white space between engraving objects.

Note: There’s one important distinction to recognize about how colors are raster

engraved in standard engraving mode vs. Color Mapping mode:

In standard engraving mode different colors are interpreted as different shades

of gray that will produce different fill patterns when engraved.

In Raster Color Mapping mode all of the different colors are engraved as if

they have a black fill. There is no way for a color to produce both a fill

pattern and be color mapped at the same time.

Loading...

Loading...