EPSON Stylus Pro 9500 Revision A

Operating Principles Component List & Illustrations 47

2.1.1.1 Carriage Mechanism

CR GUIDE RAIL

To print on paper as wide as B0 Wide, the printhead carriage must be more

stable and must travel further than the usual carriage. To make the printheads

more stable, EPSON added the CR Guide Rail to the SP 9000.

Every EPSON ink jet printer until now has used a carriage guide shaft to

stabilize the carriage during printing and horizontal movement. SP 9000 does

away with the carriage guide shaft and relies on the printer frame for its

stability.

The CR motor uses a DC motor to move the carriage, and the Linear Encoder

determines the lateral position of the carriage by counting the shaded areas of

the plastic Step Ruler (timing fence). See Figure 2-5 below. The Linear

Encoder reads the shaded stripes to determine the position of the carriage as

well as the carriage speed, and this data is sent to the software servo. To allow

for the extra distance the carriage must travel during printing, the rubber timing

belt has been changed to a belt made from steel.

The following sensors are used in combination with the CR Guide Rail

components:

o HP Sensor

This optical sensor activates when the CR Guide Rail flag (flag) enters the

space between the light emitter and the light receiver. The flag is located

just above the home position, and the HP sensor sends an “On” signal

when the carriage is in the home position.

o Linear Encoder

This encoder is mounted on the back of the carriage and outputs pulses

corresponding to the position of the slits in the timing fence that is

incorporated into the CR guide rail which are used for CR motor software

servo control and PTS (Print Timing Signal) generation. This linear

encoder has a 2-channel digital output format, with phase A and phase B,

and the resolution of each phase is 1/180 inch. Each phase is output so

that it deviates 1/720 inch from the other phase and if full edge output of

both phases is used, the minimum resolution is 1/720 inch. The CR moving

direction is monitored by the CPU through the combination of the phase A

and phase B output waveforms.

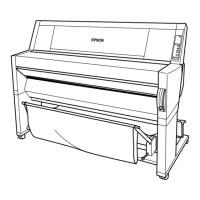

Figure 2-5. Carriage Mechanism & CR Guide Rail

Carrige

CR

MOTOR

Step Ruler

(Plastic strip w/ Shaded striper)

Linear

Encorder

HP Sensor

CR Guide Rail Flag

(Projected Area)

No HP Signal HP Signal

Carriage

Loading...

Loading...