CUTMASTER A120

0-5430 INSTALLATION

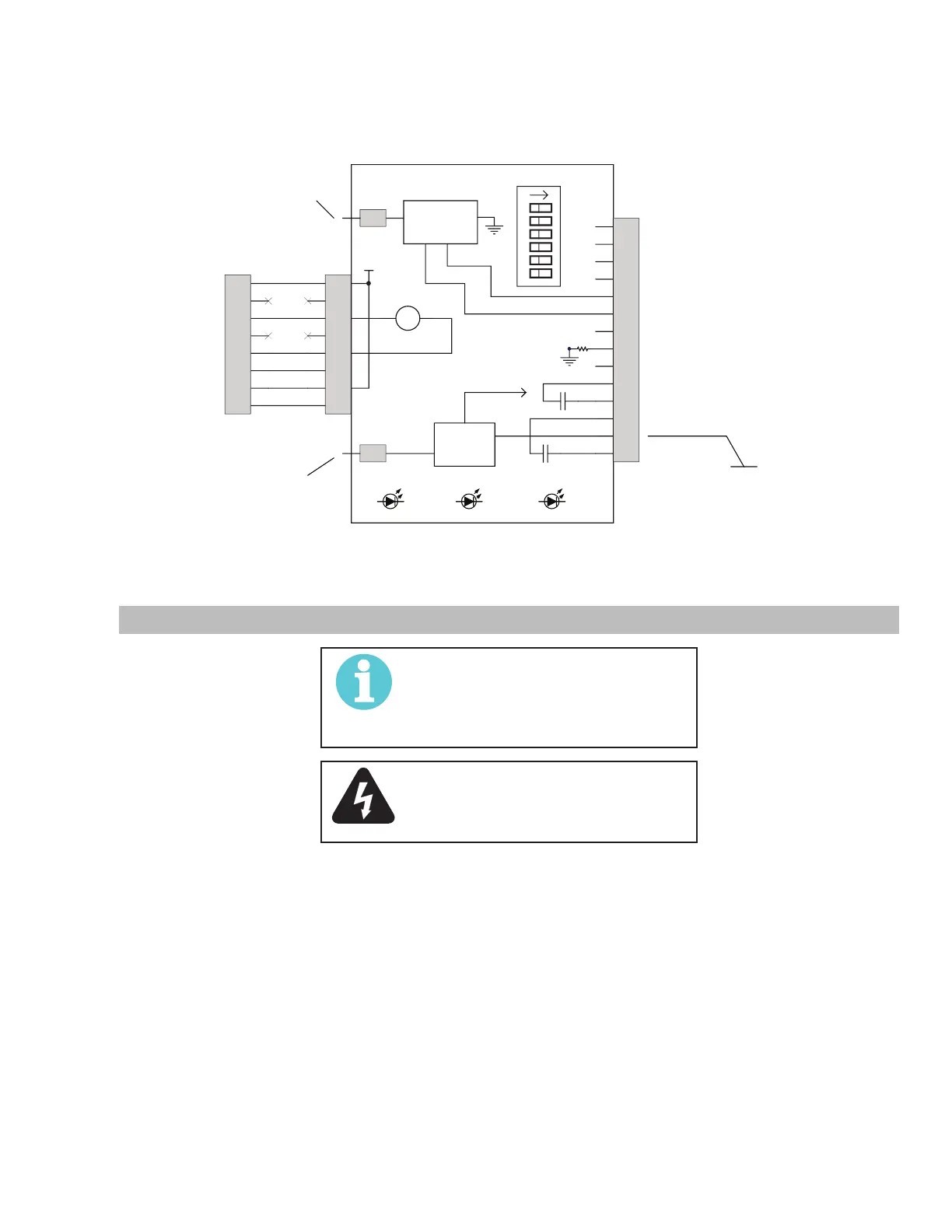

3T-3

+12V

-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

J1

1

2

3

4

5

6

7

8

*

J2

OK TO MOVE

ISO GND

SW1

DIVIDED ARC VOLTAGE (-)

DIVIDED ARC VOLTAGE (+

COMMON

PLATE CONTACT COM

PLATE CONTACT OUT

OK TO MOVE

OK TO MOVE

OHMIC

START / STOP (com)

START / STOP

OK TO MOVE

1

-V0_1

1

TIP

To -V OUT 1

on PCB1

OHMIC

SENSE

CIRCUITS

VOLTAGE

DIVIDER

CIRCUITS

+

To TIP1

on PCB1

1

2

3

4

5

6

7

8

P10

PCB4

AUTOMATION

INTERFACE PCB

(w / OHMIC)

START / STOP

DIV1-1 ON = 16.7:1 for SC11

DIV1-2 ON = 20:1 for ESAB

DIV1-3 ON = 30:1

DIV1-4 ON = 40:1 for Inova

DIV1-5 ON = 50:1 for IHT:

SC3000 & 3100; Hypertherm

®

DIV1-6 ON = 80:1 for TD iHC

DIVIDE RATIO SET BY DIP SW DIV1

CONTACT

OK to MOVE

M-ARC

START

123456

DIV1

CONTACT

Art # A-09819_AC

ISO GND

3. Connect CNC to the power supply.

3T.04 Setting Up Automation or Machine Torch

NOTE!

An adapter is required to be installed in

the power supply if converting a hand

torch system to operate a machine or

automation torch.

WARNING

Disconnect primary power at the source

before disassembling the torch or torch

leads.

The Automation and Machine torch include a positioning tube with rack and pinch block assembly.

1. Mount the torch assembly on the cutting table.

2. To obtain a clean vertical cut, use a square to align the torch perpendicular to the surface of the workpiece.

Loading...

Loading...