CUTMASTER A120

0-5430 OPERATION

4T-7

• Air quality

• Line voltage uctuations

• Torch standoff height

• Proper work cable connection

4T.07 Gouging

WARNING

Be sure the operator is equipped with

proper gloves, clothing, eye and ear

protection and that all safety precau-

tions at the front of this manual have

been followed. Make sure no part of

the operator’s body comes in contact

with the workpiece when the torch is

activated.

Disconnect primary power to the system

before disassembling the torch, leads,

or power supply.

!

CAUTION

Sparks from plasma gouging can cause

damage to coated, painted or other sur-

faces such as glass, plastic, and metal.

Check torch parts. The torch parts must

correspond with the type of operation.

Refer to Section 4T.09, Torch Parts

Selection.

Gouging Parameters

Gouging performance depends on parameters such

as torch travel speed, current level, lead angle (the

angle between the torch and workpiece), and the dis-

tance between the torch tip and workpiece (standoff).

!

CAUTION

Touching the torch tip or shield cup to

the work surface will cause excessive

parts wear.

Torch Travel Speed

NOTE!

Refer to Appendix Pages for additional

information as related to the Power Sup-

ply used.

Optimum torch travel speed is dependent on current

setting, lead angle, and mode of operation (hand or

machine torch).

Current Setting

Current settings depend on torch travel speed,

mode of operation (hand or machine torch), and the

amount of material to be removed.

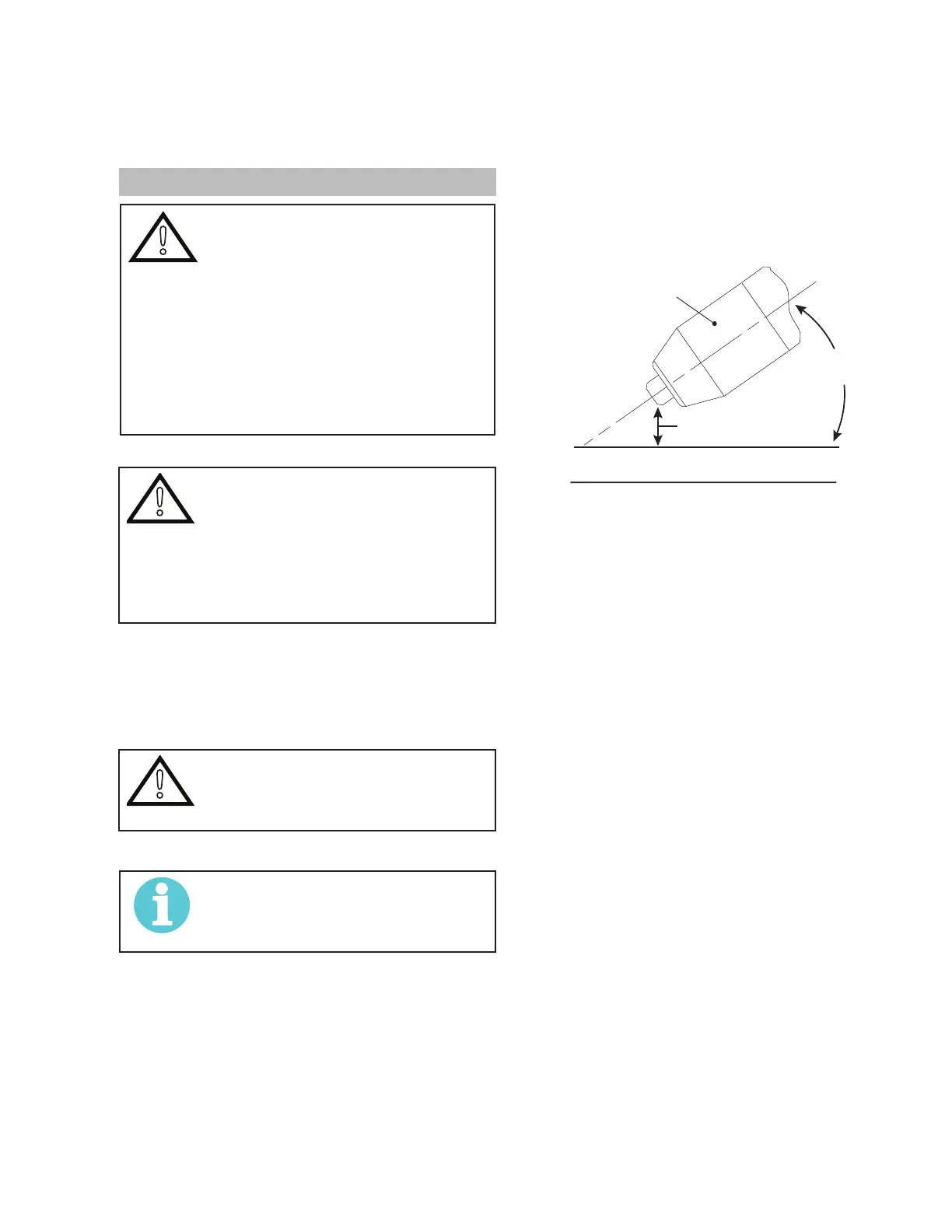

Lead Angle

The angle between the torch and workpiece depends

on the output current setting and torch travel speed.

The recommended lead angle is 35°. At a lead angle

greater than 45° the molten metal will not be blown

out of the gouge and may be blown back onto the

torch. If the lead angle is too small (less than 35°),

less material may be removed, requiring more pass-

es. In some applications, such as removing welds

or working with light metal, this may be desirable.

Workpiece

Torch Head

Standoff Height

Gouging Angle and Standoff Distance

Standoff Distance

The tip to work distance affects gouge quality and

depth. Standoff distance of 1/8 - 1/4 inch (3 - 6

mm) allows for smooth, consistent metal removal.

Smaller standoff distances may result in a severance

cut rather than a gouge. Standoff distances greater

than 1/4 inch (6 mm) may result in minimal metal

removal or loss of transferred main arc.

Slag Buildup

Slag generated by gouging on materials such as car-

bon and stainless steels, nickels, and alloyed steels,

can be removed easily in most cases. Slag does not

obstruct the gouging process if it accumulates to the

side of the gouge path. However, slag build - up can

cause inconsistencies and irregular metal removal

if large amounts of material build up in front of the

arc. The build - up is most often a result of improper

travel speed, lead angle, or standoff height.

Loading...

Loading...