148

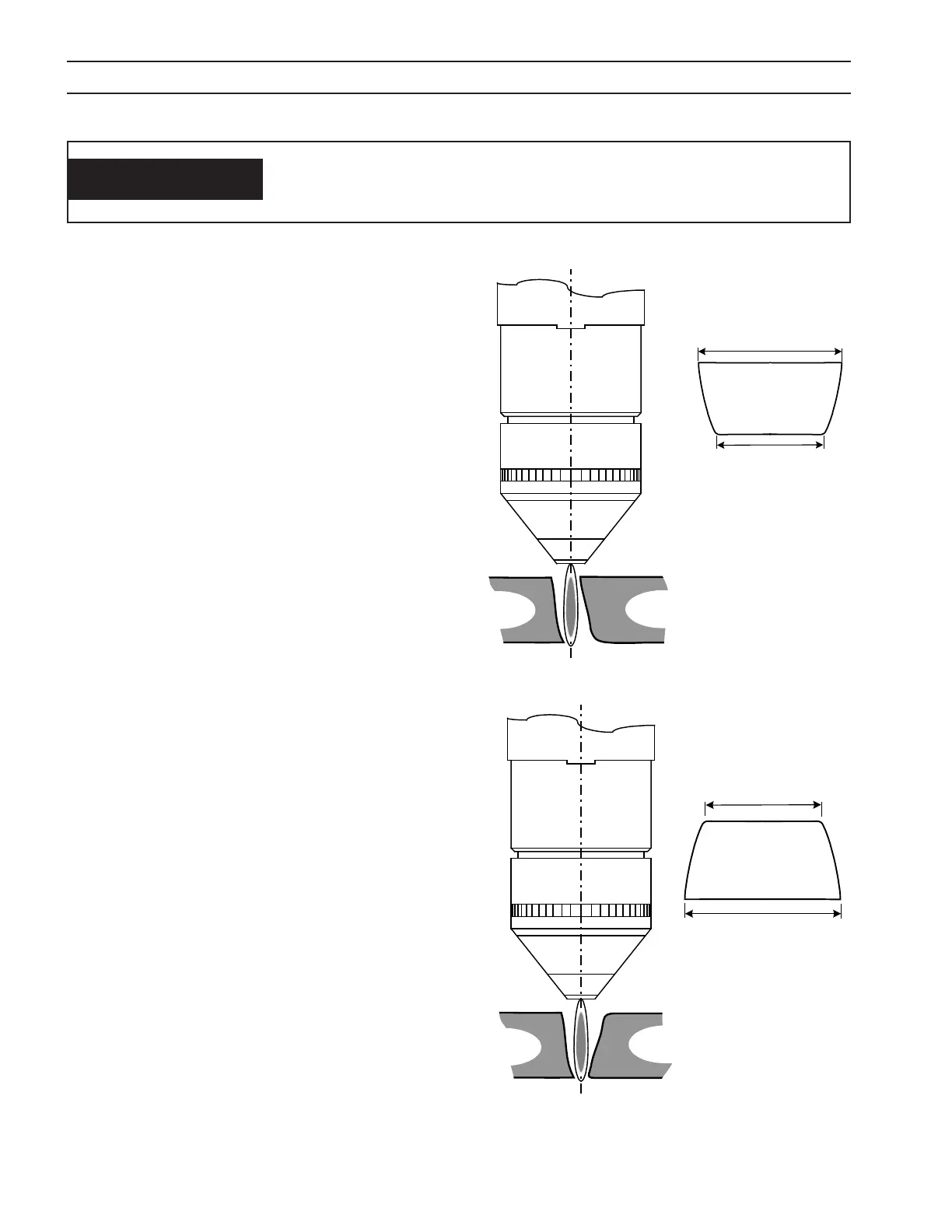

Positive Cut Angle

Top dimension is less than the bottom dimension.

Misaligned torch•

Bent or warped material•

Worn or damaged consumables•

High stando High (arc voltage)•

Cutting speed fast•

Current high or low. (See Process Data for recom-•

mended current level for specic nozzles).

Part

Drop

Part

Before attempting ANY corrections, check cutting variables with the

factory recommended settings/consumable part numbers listed in

Process Data.

4.2.2. Cut Angle

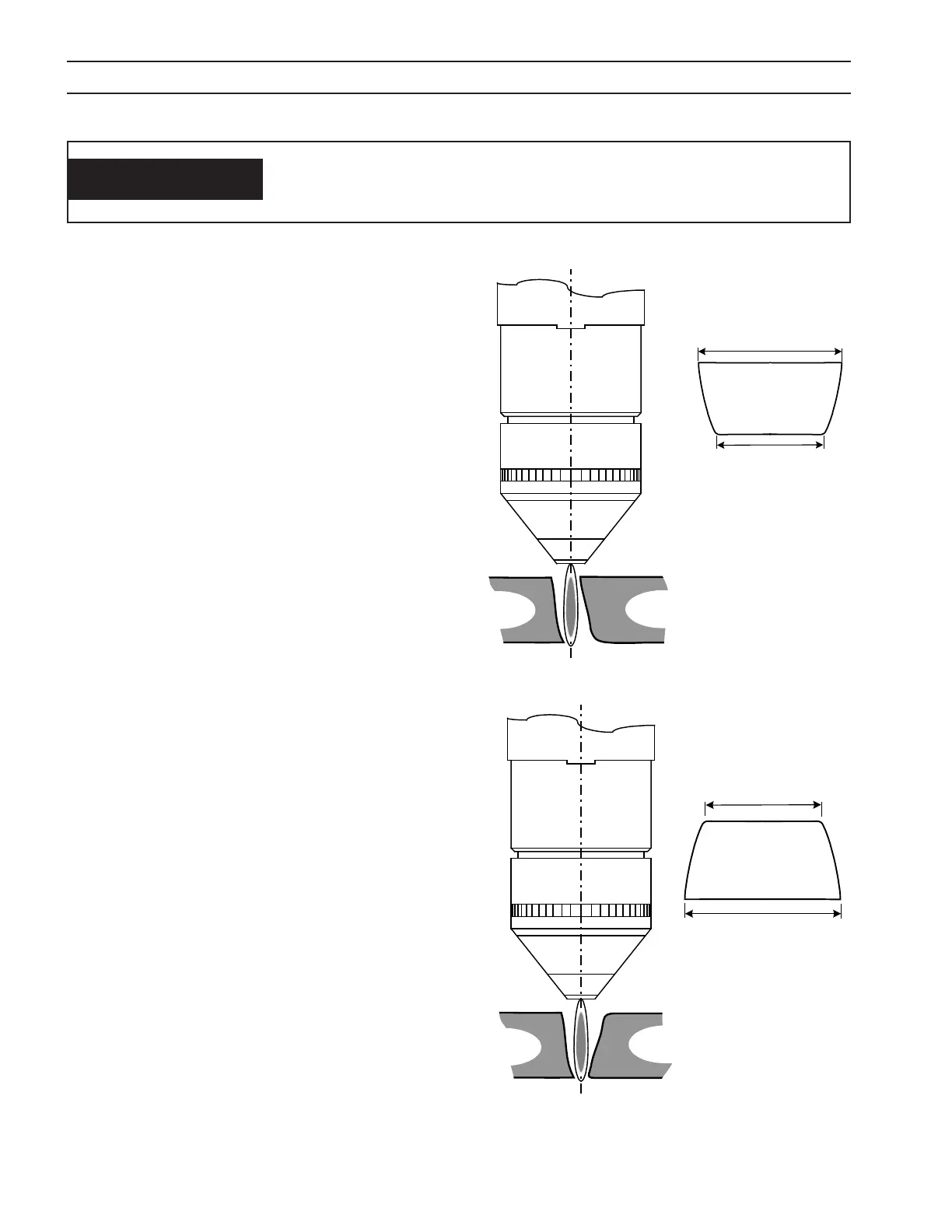

Negative Cut Angle

Top dimension is greater than the bottom.

Misaligned torch•

Bent or warped material•

Worn or damaged consumables•

Stando low (arc voltage)•

Cutting speed slow (machine travel rate)•

Part

Part

Drop

SECTION 4 OPERATION

CAUTION

Loading...

Loading...