157

Nozzle

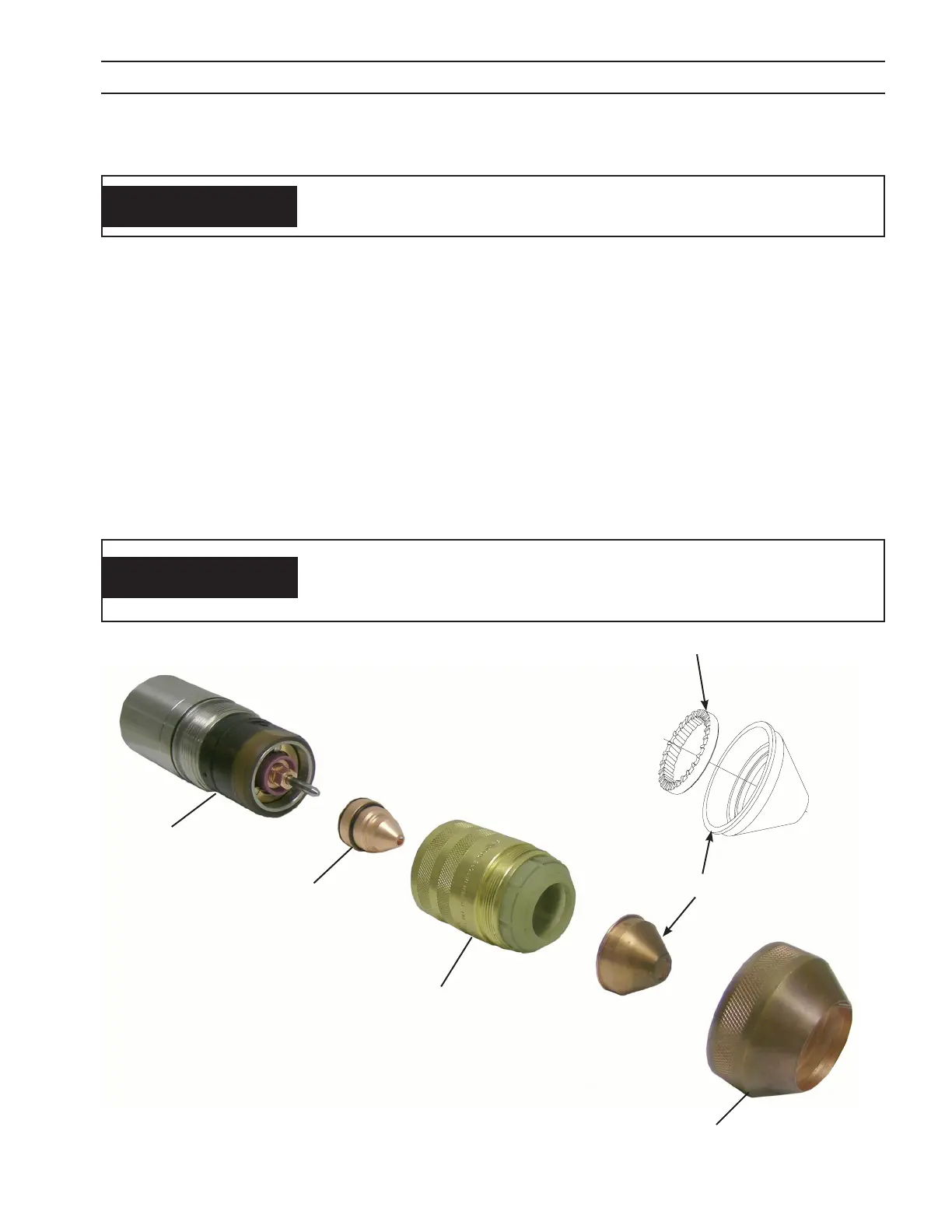

5.3 Torch Front End Disassembly (for Production Thick Plate)

1. Remove the Shield Cup Retainer.

NOTE:

If the shield cup retainer is dicult to remove, try to screw the nozzle retaining cup tighter to relieve pres-

sure on the shield cup retainer.

2. Inspect mating metal surface of shield cup and shield cup retainer for nicks or dirt that might prevent these

two parts from forming a metal to metal seal. Look for pitting or signs of arcing inside the shield cup. Look

for melting of the shield tip. Replace if damaged.

3. Inspect diuser for debris and clean as necessary. Wear on the top notches does occur, eecting gas volume.

Replace this part every other shield replacement. Heat from cutting many small parts in a concentrated area

or when cutting material greater than 0.75" (19.1mm) may require more frequent replacement.

Shield Cup Retainer

Nozzle Retaining Cup

Torch Body

DANGER

HOT TORCH WILL BURN SKIN!

ALLOW TORCH TO COOL BEFORE SERVICING.

Shield Cup

Diuser

CAUTION

Incorrect assembly of the diuser in the shield will prevent the torch

from working properly. Diuser notches must be mounted away

from the shield as illustrated.

SECTION 5 MAINTENANCE

Loading...

Loading...