150

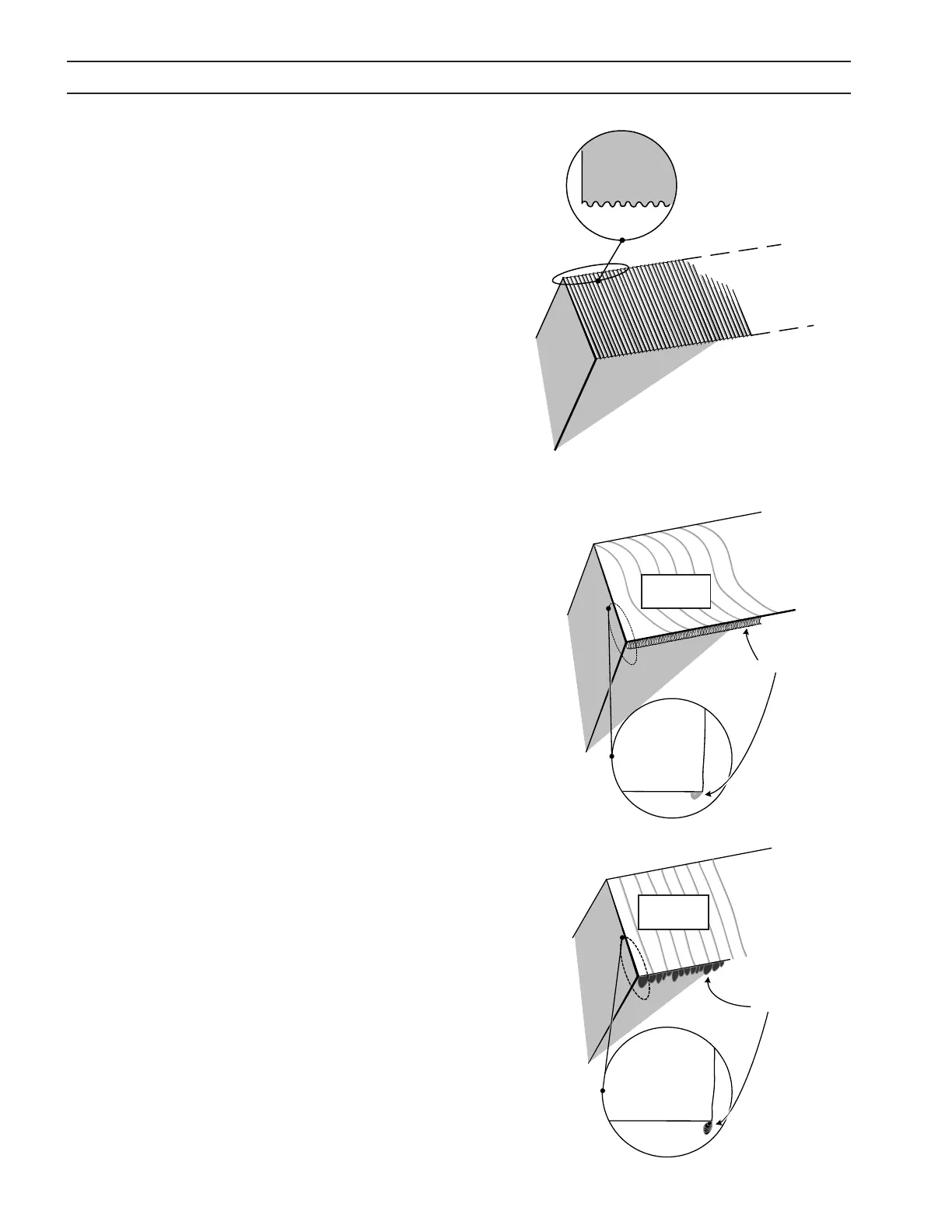

4.2.4. Surface Finish

Process Induced Roughness

Cut face is consistently rough. May or may not be conned to

one axis.

Incorrect Shield Gas mixture (See Process Data).•

Worn or damaged consumables.•

Machine Induced Roughness

Can be dicult to distinguish from Process Induced Roughness.

Often conned to only one axis. Roughness is inconsistent.

Dirty rails, wheels and/or drive rack/pinion. (Re-•

fer to Maintenance Section in machine operation

manual).

Carriage wheel adjustment.•

or

Machine

Induced

Roughness

Process

Induced

Roughness

Cut Face

Top View

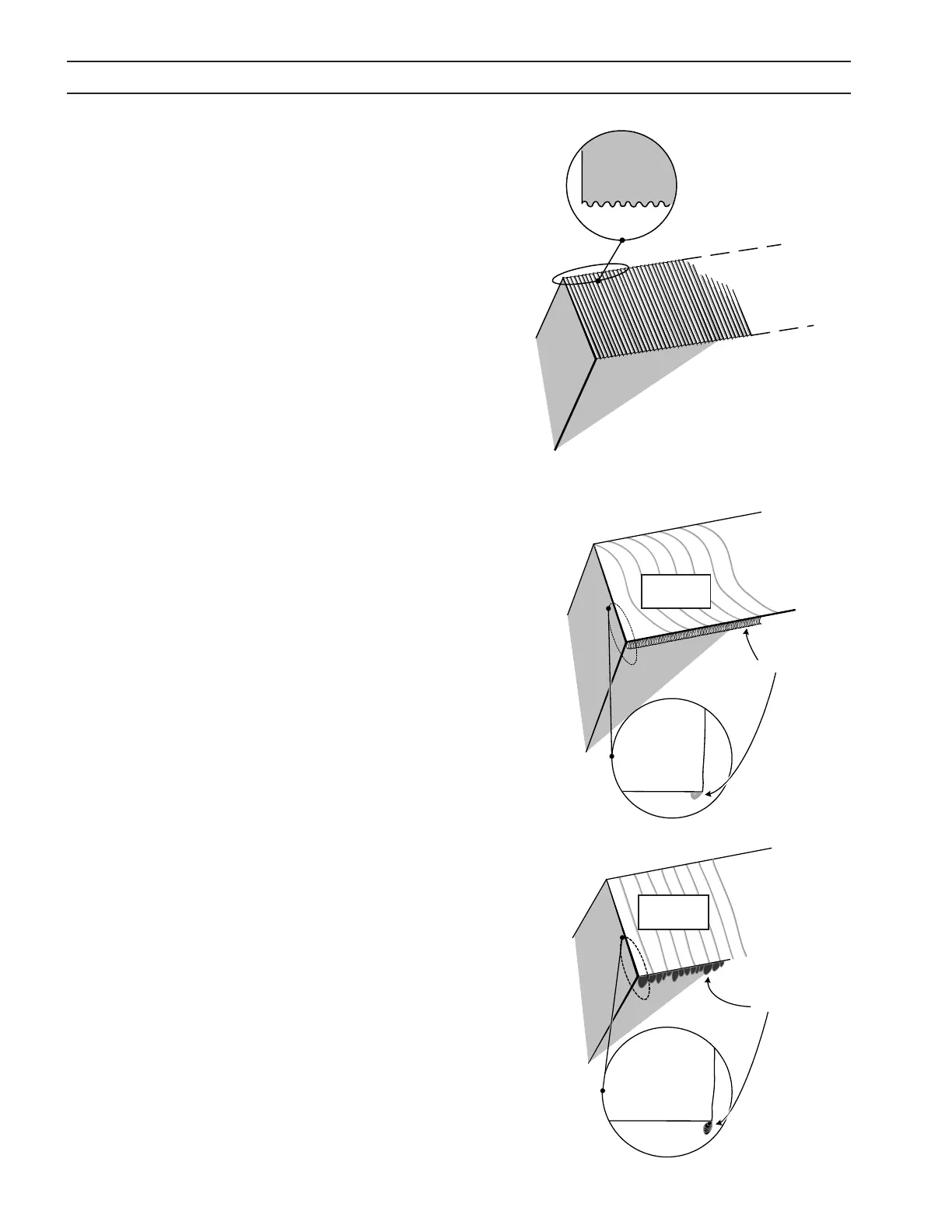

4.2.5. Dross

Dross is a by-product of the cutting process. It is the undesirable ma-

terial that remains attached to the part. In most cases, dross can be

reduced or eliminated with proper torch and cutting parameter setup.

Refer to Process Data.

High Speed Dross

Material weld or rollover on bottom surface along kerf. Dicult to re-

move. May require grinding or chipping. “S” shaped lag lines.

Stando high (arc voltage)•

Cutting speed fast•

Slow Speed Dross

Forms as globules on bottom along kerf. Removes easily.

Cutting speed slow•

Side View

Cut Face

Rollover

Lag Lines

Side View

Globules

Cut Face

Lag Lines

SECTION 4 OPERATION

Loading...

Loading...