94

11-2 General information

Operational precautions

y This Section concerns disassembly of the crankcase for repair purpose.

y Remove following components before disassembling crankcase.

-Engine remove Section 5

-Cylinder head Section 6

-Cylinder and piston Section 7

-Drive face and driven pulley Section 8

-AC generator/Start one way clutch Section 10

y In case it requires replacing the crankshaft bearing, the driving chain of engine oil pump or the timing

chain, it is preferably to replace crankshaft as a unit.

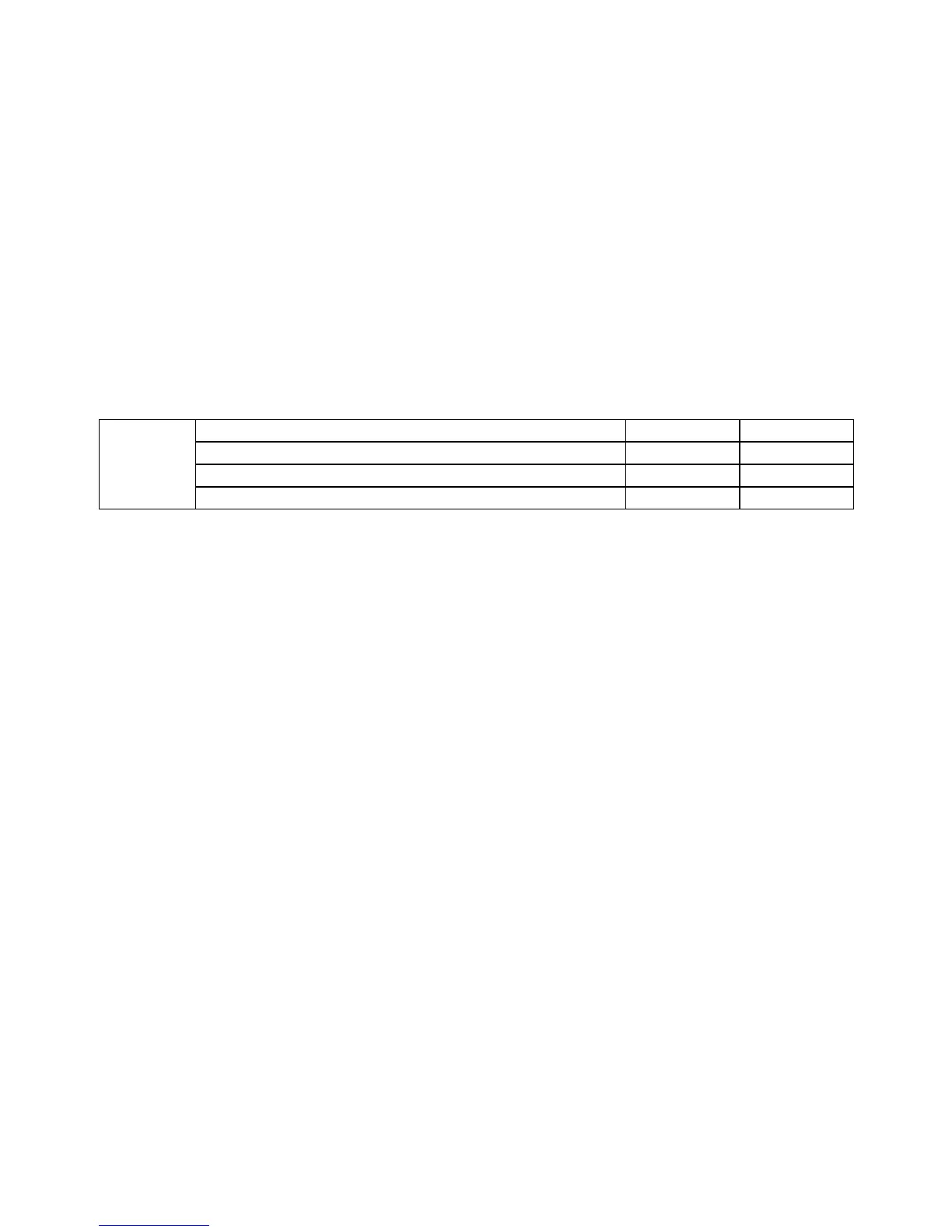

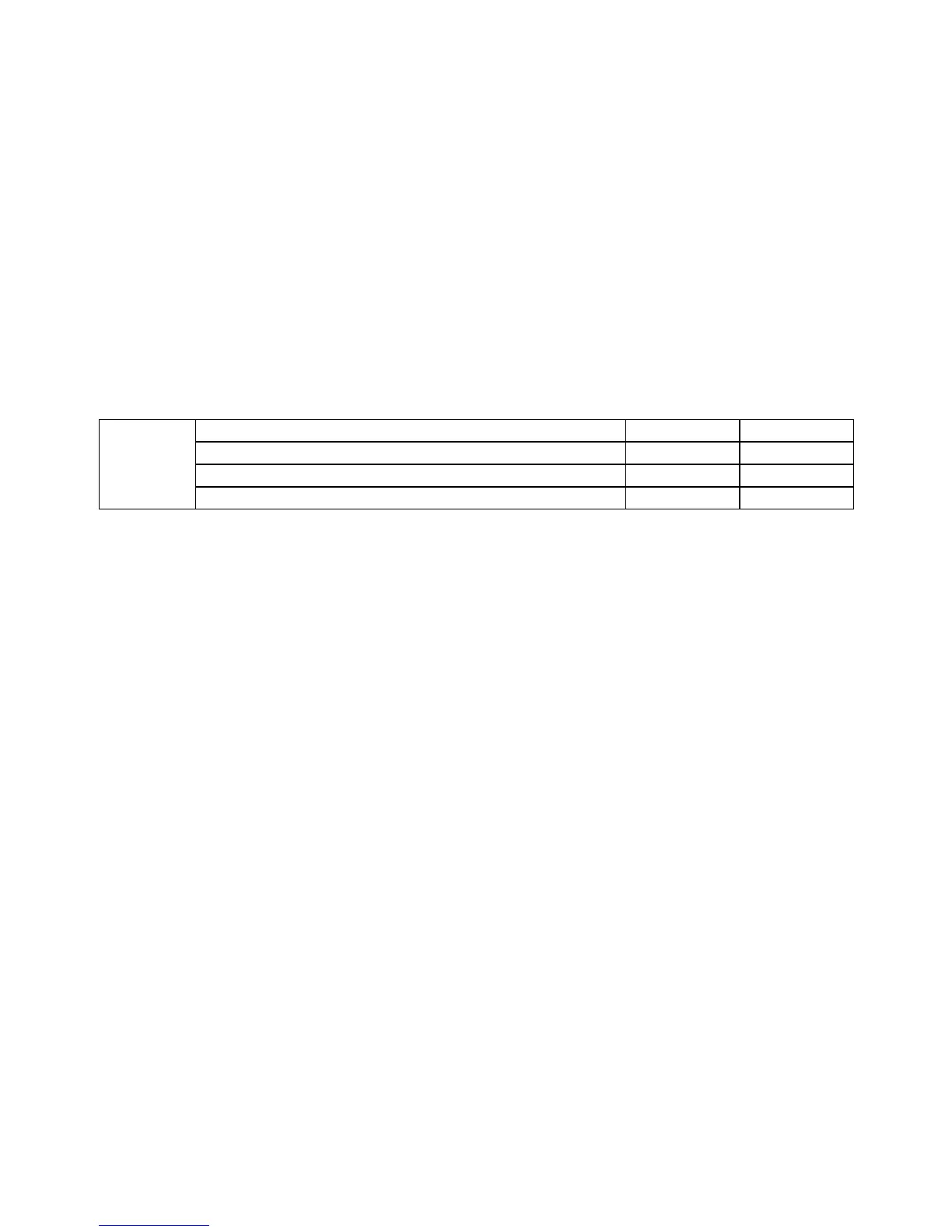

Specification Unit: mm

Item Standard Limit

Connecting rod side clearance of the big end 0.100~0.400 0.600

Vertical clearance of the big end of the connecting rod 0~0.008 0.050

Crankshaft

Run-out 0.030 0.100

Torque value

Bolts for crankcase 0.8~1.2kgf-m

Engine oil drain bolt 3.5~4.5kgf-m

Cylinder stud bolt 1.0~1.4kgf-m

Tools

Special tools

L. crank shaft oil seal driver (27*42*7): SYM-1332100-HMA

11-3 Trouble diagnosis

Engine noise

y Loose crankshaft bearing

y Loose crankshaft pin bearing

y Worn out piston pin and pin hole

Loading...

Loading...