IONPURE

®

MX CEDI Modules

Page 12 of 32 IP-MAN-MX-Rev E

3. MX MODULE INSTALLATION

3.1. Moving the MX Module Into Place

Confirm that the pre-installation requirements outlined in Section 2 are met and the

system is ready for MX Module installation.

• Remove any packaging materials and move the module to its operating location. (See

section 2.1.1). Use safe lifting practices when moving the module.

• Remove the plug caps that seal the inlet and outlet ports on the cathode end.

3.2. Connect Plumbing Fittings

• Make sure all upstream pretreatment equipment and piping have been thoroughly

flushed with particle-free water before connecting them to the MX module.

• Flushing removes any particles left in the piping from cutting and assembly. If particles

remain, they could plug the passages inside the MX Module.

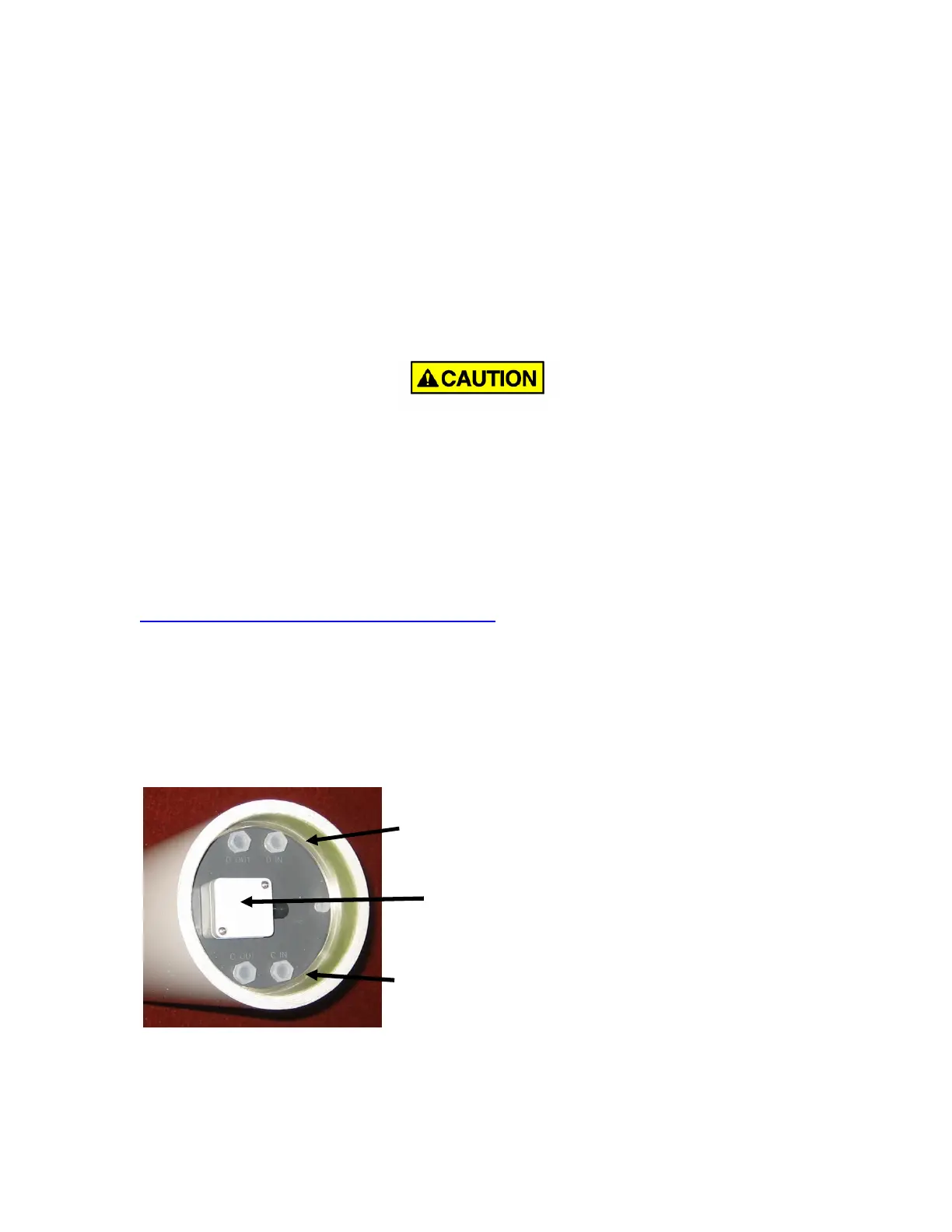

• Figure 3-1 and the drawing in Appendix B show the location of the module plumbing

connections. The product and reject ports are all 3/8” BSP tapered female. These

connections are British Standard Pipe thread which is NOT the same as National Pipe

Thread (NPT) !!! For more information on BSP thread, go to the web site

www.britishfasteners.com/threads/bsp.html.

• Non-metallic fittings are required - do not connect metal fittings directly to MX module.

• Do not over tighten the fittings. Over tightening can result in damage to the module

that can only be fixed in the factory. Teflon

®

tape may be used in the threads to ensure

a good seal.

• All plumbing connections are made to the cathode end (low voltage). The anode end

does not have plumbing ports.

Figure 3-1: MX plumbing connections – cathode end

Cathode junction box

Loading...

Loading...