Maintenance

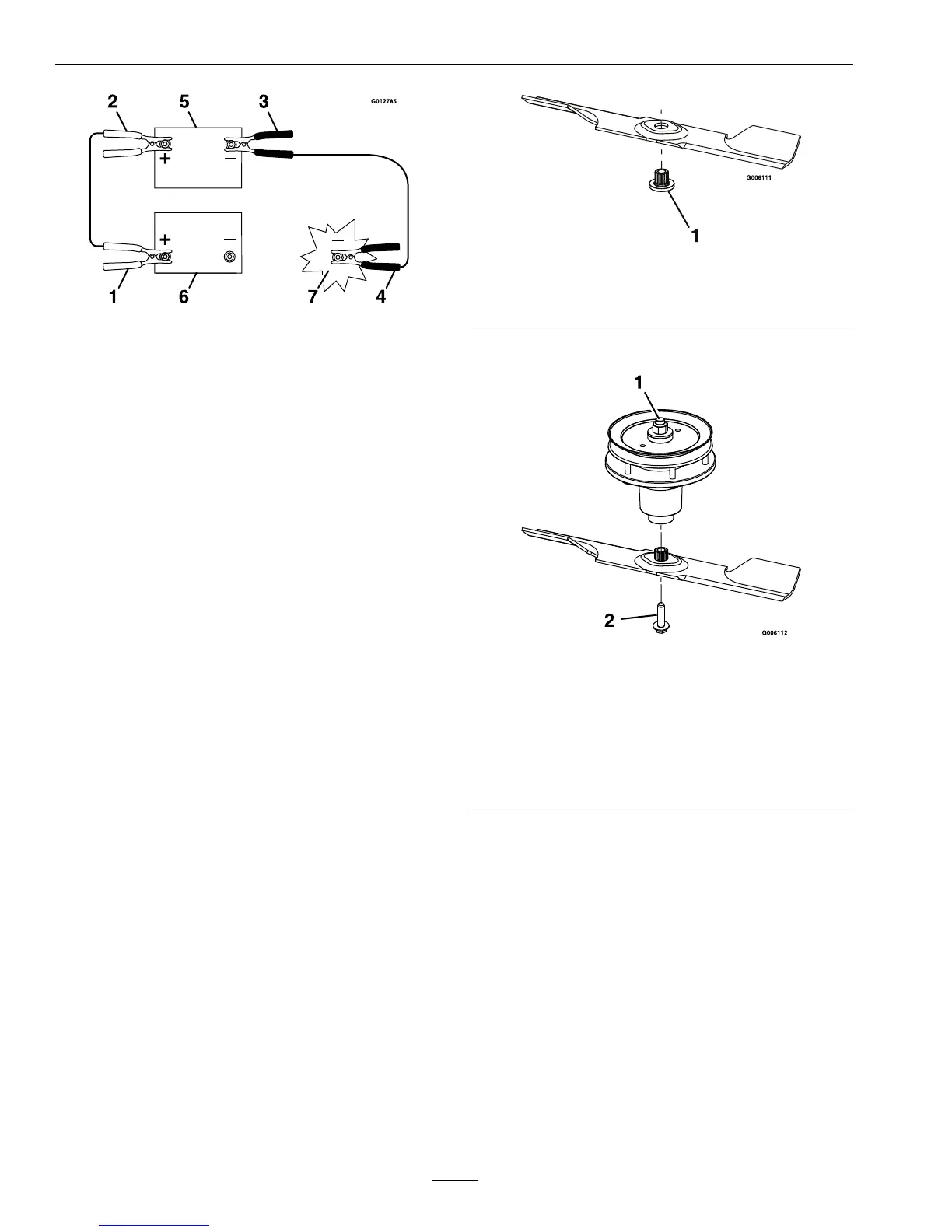

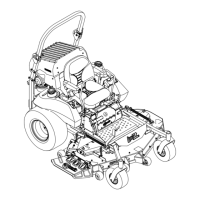

Figure13

1.Positive(+)cableondischargedbattery

2.Positive(+)cableonboosterbattery

3.Negative(–)cableontheboosterbattery

4.Negative(–)cableontheengineblock

5.Boosterbattery

6.Dischargedbattery

7.Engineblock

4.Connecttheotherendofthepositivecabletothe

positiveterminaloftheboosterbattery.

5.Connecttheblacknegative(–)cabletotheother

terminal(negative)oftheboosterbattery.

6.MAKETHEFINALCONNECTIONON

THEENGINEBLOCKOFTHESTALLED

VEHICLE(NOTTOTHENEGATIVEPOST)

AWAYFROMTHEBATTERY .STANDBACK.

7.Startthevehicleandremovethecablesinthe

reverseorderofconnection(theengineblock

(black)connectionisthersttodisconnect).

CheckMowerBlades

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Liftdeckandsecureinraisedpositionasstated

intheCleanGrassBuild-UpUnderDeck

procedure.

3.Inspectbladesandsharpenorreplaceasrequired.

4.Reinstalltheblades(iftheywereremoved)inthe

followingorder:

A.Installbushingthroughbladewithbushing

angeonbottom(grass)sideofblade.

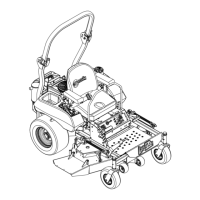

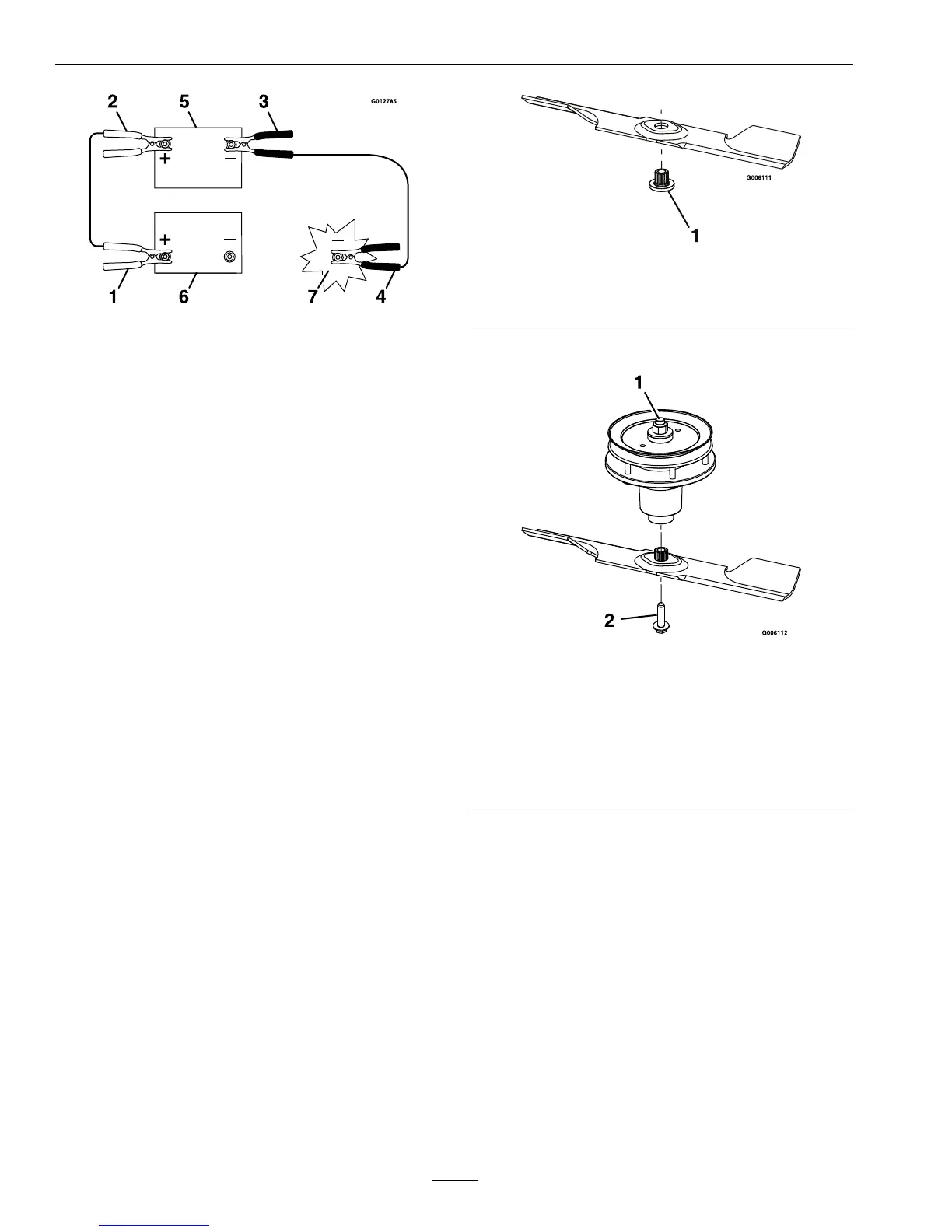

Figure14

1.Installbushinginbladepriortoinstallingbushingin

spindle.

B.Installbushing/bladeassemblyintospindle.

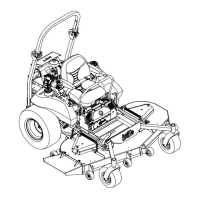

Figure15

1.Usewrenchherefor

bladeinstallation.This

nuthasbeentorquedto

90–110ft-lb(122–149

N-m)

2.Torqueto55-60ft-lb

(75-81N-m)Apply

lubricanttothreads

asneededtoprevent

seizing.Copper-based

anti-seizepreferable.

Greaseacceptable

substitute.

C.Applylubricanttothreadsofbladeboltas

neededtopreventseizing.Copper-based

anti-seizepreferable.Greaseacceptable

substitute.Installbladeboltngertight.Place

wrenchonthetopspindlenutthentorquethe

bladeboltsto55-60ft-lb(75-81N-m).

32

Loading...

Loading...