Maintenance

2.Checktirepressureindrivetires.

3.Inatedrivetiresto10psi(69kPa).

4.Semi-pneumaticcastertiresdonotneedtobe

inated.

Note:DoNotaddanytypeoftirelinerorfoam

llmaterialtothetires.Excessiveloadscreatedby

foamlledtiresmaycausefailurestothehydrodrive

system,frame,andothercomponents.Foamlling

tireswillvoidthewarranty.

CheckConditionOfBelts

ServiceInterval:Every40hours

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Unhookseatlatchandtiltseatup.Removethe

airdetectorpanelonfrontsideoftheengine

compartmenttocheckpumpdrivebeltand

alternatorbelt.

3.Removeleftandrightbeltshieldsondeckandlift

upoorpantoinspectdeckdrivebelt.

4.Checkundermachinetoinspectthemule

drivebelt.RefertoMuleDriveBeltTension

AdjustmentsectioninAdjustments.

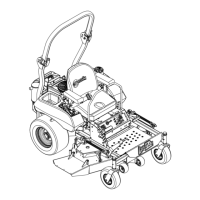

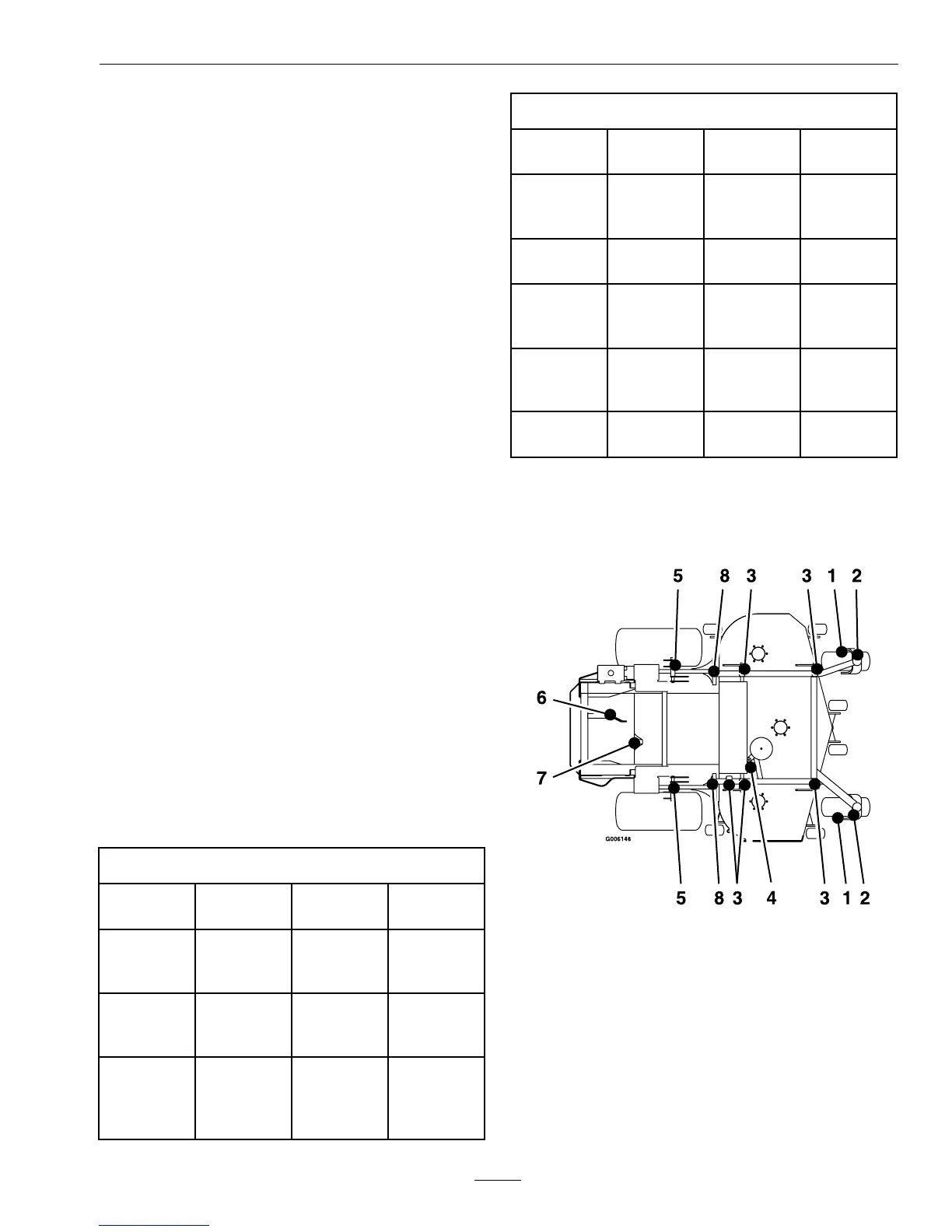

LubricateGreaseFittings

Note:Seechartforserviceintervals.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Lubricatettingswithonetotwopumpsof

NGLIgrade#2multi-purposegungrease.

Refertothefollowingchartforttinglocations

andlubricationschedule.

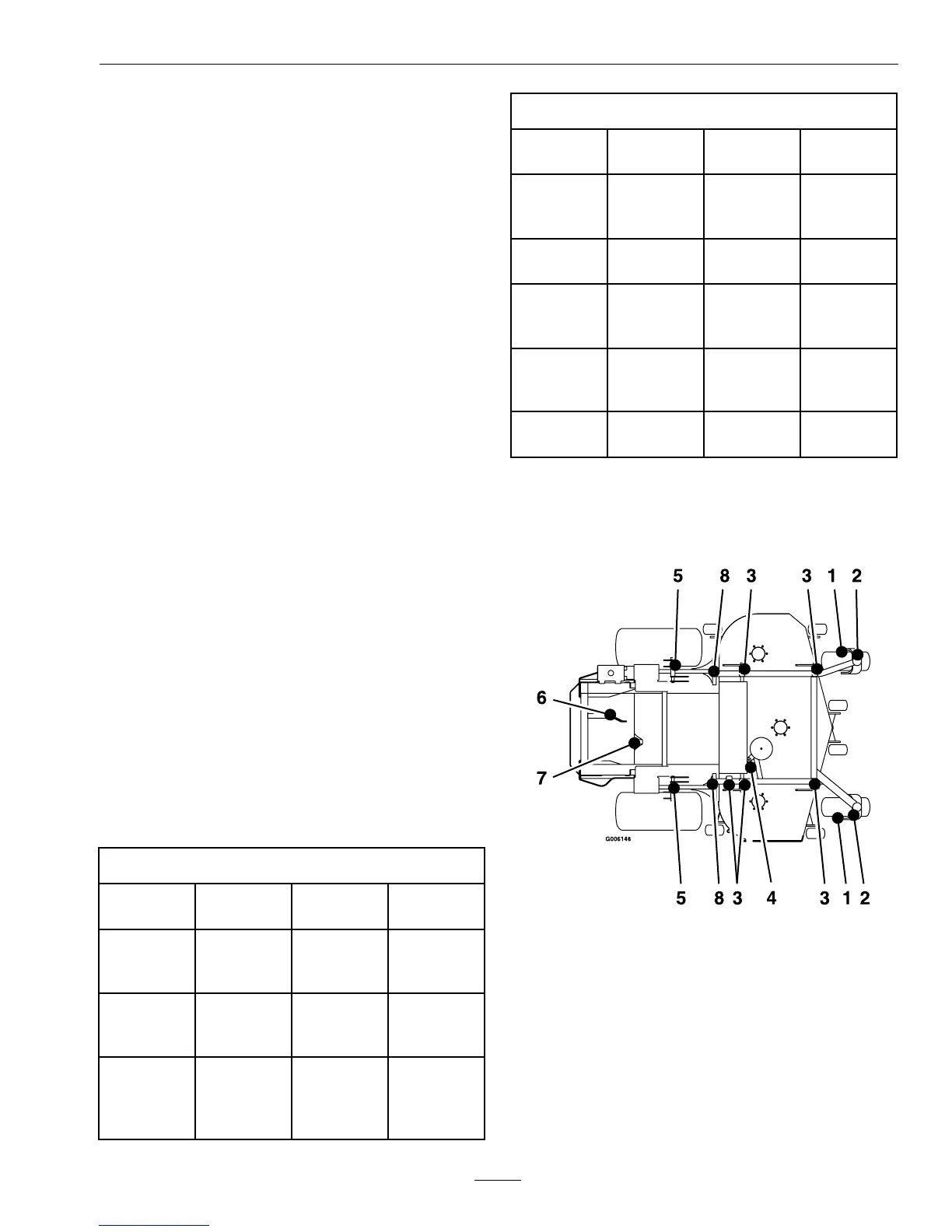

LubricationChart

Fitting

Locations

Initial

Pumps

Numberof

Places

Service

Interval

1.Front

Casterwheel

hubs

*0

2

*Yearly

2.Front

Caster

Pivots

*0

2

*Yearly

3.Height

Adjustment

Shaft

Bearings

1

540Hours

LubricationChart

Fitting

Locations

Initial

Pumps

Numberof

Places

Service

Interval

4.Deck

DriveBelt

IdlerArm

11

Yearly

5.Brake

Brackets

12

200Hours

6.Mule

DriveBelt

IdlerArm

11

Yearly

7.Pump

DriveBelt

IdlerArm

11

Yearly

8.Deck

RearStruts

12

40Hours

*Seestep3forspeciallubricationinstructionson

thefrontcasterpivotsandtheLubricateCaster

WheelHubssectionforspeciallubrication

instructionsonthefrontcasterswheelhubs.

Number6(MuleDriveBeltIdlerArm)Located

UnderEngineFrame

Number7(PumpDriveBeltIdlerArm)Located

UnderEngineFrame

3.Lubricatefrontcasterpivotsonceayear.Remove

hexplugandcap.Threadgreasezerkinholeand

pumpwithgreaseuntilitoozesoutaroundtop

bearing.Removegreasezerkandthreadplugback

in.Placecapbackon.

35

Loading...

Loading...