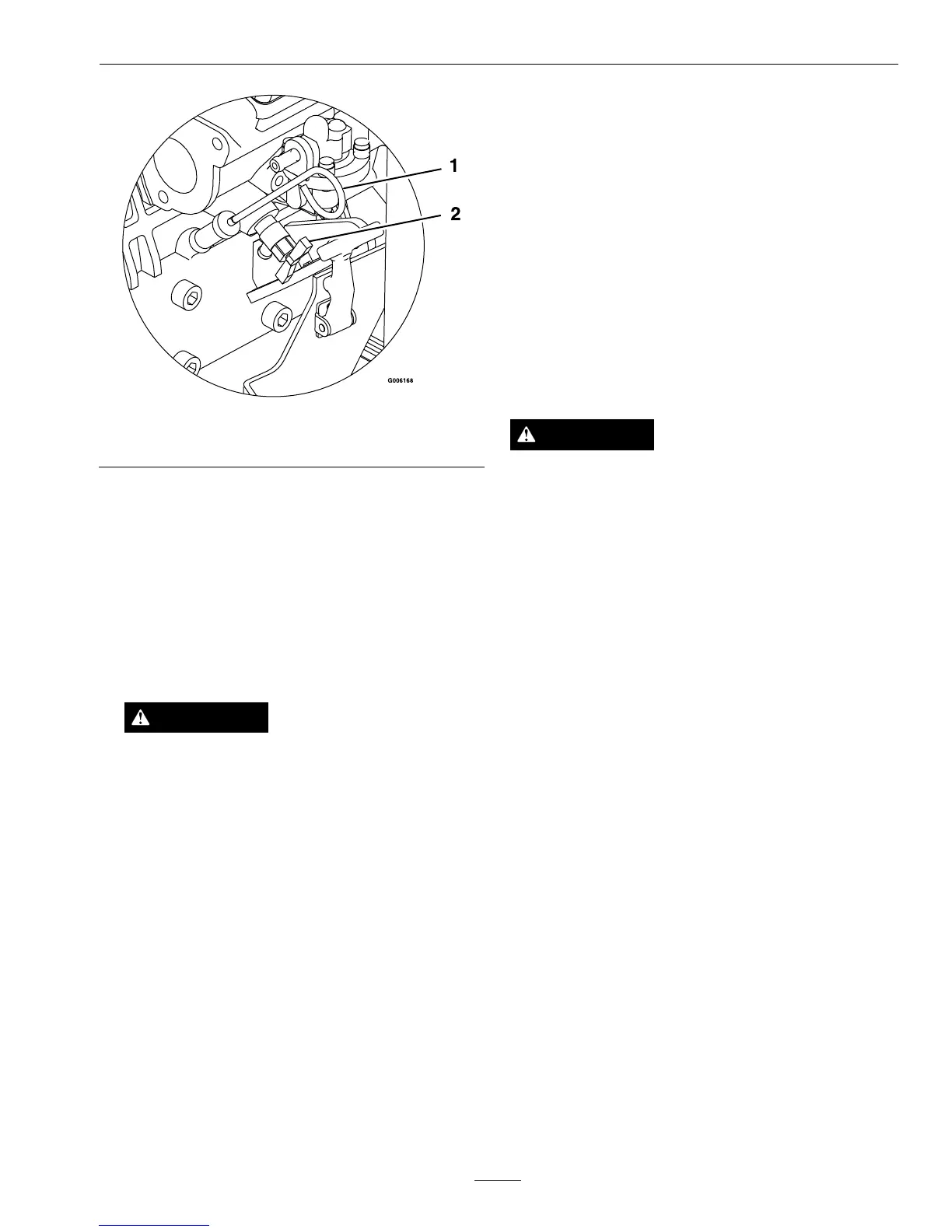

Maintenance

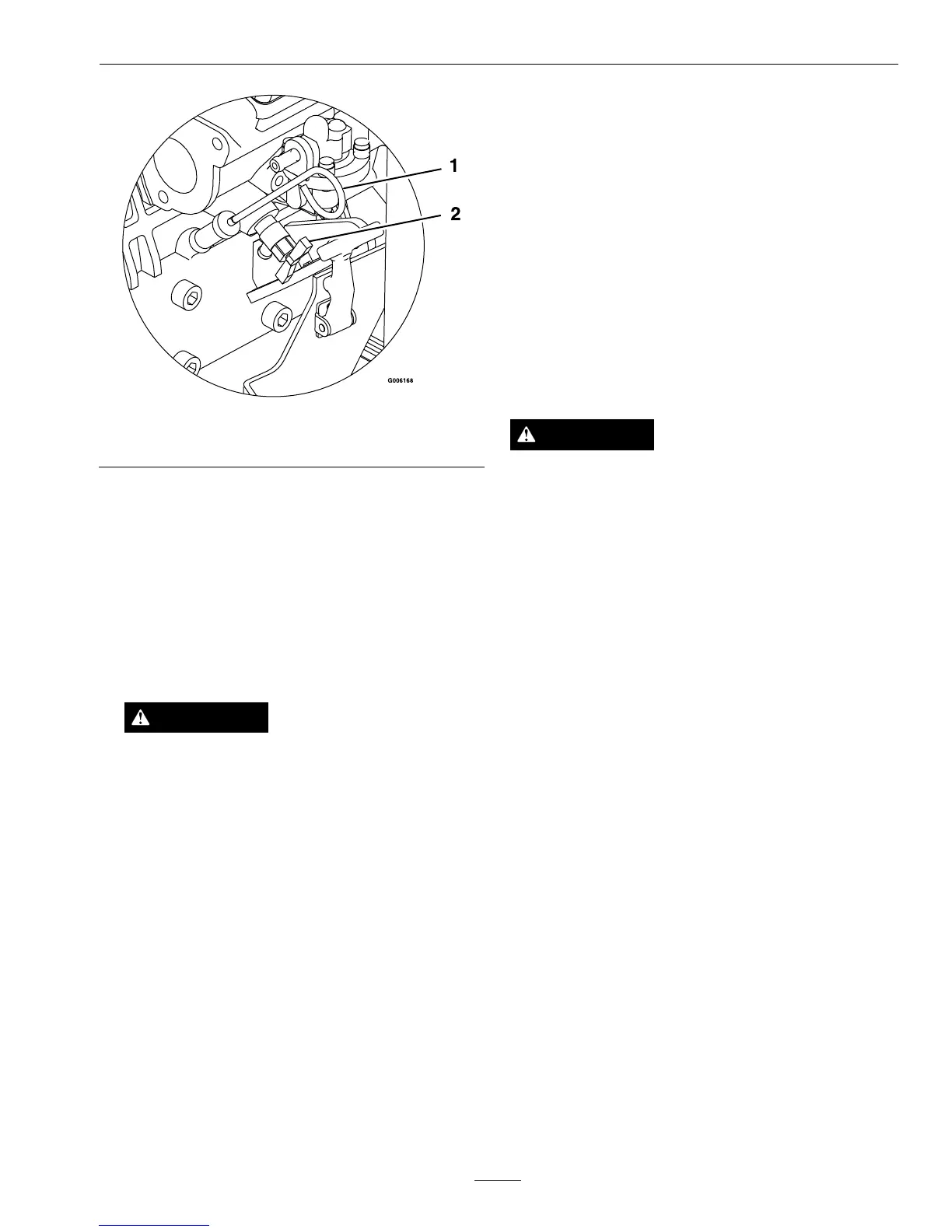

Figure17

1.Oildipstick

2.Draincock

4.Reinstallalldrainplugsandhosesandtighten

draincock.

5.Fillradiatorwitha50/50mixofwaterand

Dex-Cool©coolantasspeciedintheCheck

EngineCoolantLevelSection,allowingsome

room(approximately1/2inch(12.7mm))for

expansion.Add50/50coolantmixtooverow

bottleontheleftsideoftheengineasrequired

tobringtheleveluptotheindicatorlineonthe

bottle.

WARNING

Enginecompartmentcontainsopenbelt

drives,fans,andotherrotatingcomponents

thatcancauseinjury.Fingers,hands,loose

clothing,orjewelrycangetcaughtbythe

rotatingfananddriveshaft.

•DoNotoperatemachinewithoutthe

coversinplace.

•Keepngers,hands,andclothingclearof

rotatingcomponents.

•Shutoffengine,waitformovingpartsto

stop,engageparkingbrakeandremove

key,beforeperformingmaintenance.

6.Withthecapofftheradiator,tilthoodclosedand

puttheseatdown.Starttheengineasstatedin

theOperatingInstructionsSection.Returnthe

seatupandhoodforwardtotheopenposition.

7.Operateengineuntiltheenginethermostatopens

andcoolantiscirculatingthroughtheradiator

core.Asairispurgedfromtheengineblockand

thecoolantleveldrops,addadditionalcoolantto

theradiator.

8.Whentheradiatoriscompletelyfullandno

additionalcoolantcanbeadded,continuerunning

andinstalltheradiatorcap.Makesurethatthe

capiscompletelyseatedbypressingdownrmly

whileturninguntilthecapstops.Oncethecapis

installed,theenginemaybestopped.

CheckSparkArrester

(ifequipped)

ServiceInterval:Every50hours

WARNING

Hotexhaustsystemcomponentsmayignitefuel

vaporsevenaftertheengineisstopped.Hot

particlesexhaustedduringengineoperationmay

igniteammablematerials.Firemayresultin

personalinjuryorpropertydamage.

DoNotrefuelorrunengineunlesssparkarrester

isinstalled.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Waitformufertocool.

3.Ifanybreaksinthescreenorweldsareobserved,

replacearrester.

4.Ifpluggingofthescreenisobserved,remove

arresterandshakelooseparticlesoutofthe

arresterandcleanscreenwithawirebrush(soak

insolventifnecessary).Reinstallarresteron

exhaustoutlet.

ThreadLockingAdhesives

Threadlockingadhesivessuchas“Loctite242”

or“Fel-Pro,Pro-LockNutType”areusedonthe

followingfasteners:

•Pumpdrivesheavesetscrews.

•SquareheadsetscrewsonHydropumpcontrol

arms.

•Sheaveretainingboltintheendofengine

crankshaft.

•Casterwheelspacernuts.

39

Loading...

Loading...