Maintenance

CAUTION

Raisingthemowerdeckforserviceor

maintenancerelyingsolelyonmechanical

orhydraulicjackscouldbedangerous.The

mechanicalorhydraulicjacksmaynotbeenough

supportormaymalfunctionallowingtheunitto

fall,whichcouldcauseinjury.

DoNotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstandsor

equivalentsupport.

1.Thisadjustmentmustbemadewiththedrive

wheelsturning.Firstraisetherearofmachine

upandsupportwithjackstands(orequivalent

support)justhighenoughtoallowthedrive

wheelstorotatefreely.

2.Unhookseatlatchandtiltseatforward.

3.Removetheelectricalconnectionfromtheseat

safetyswitch,locateddirectlytotheleftoftheseat

switchassemblybesidethehydraulicoilreservoir.

Temporarilyinstallajumperwireacrossthe

terminalsintheconnectorofthemainwiring

harness.

4.Runtheunitatleast5minuteswiththedrive

leversatfullforwardspeedtobringhydraulic

systemoiluptooperatingtemperature.

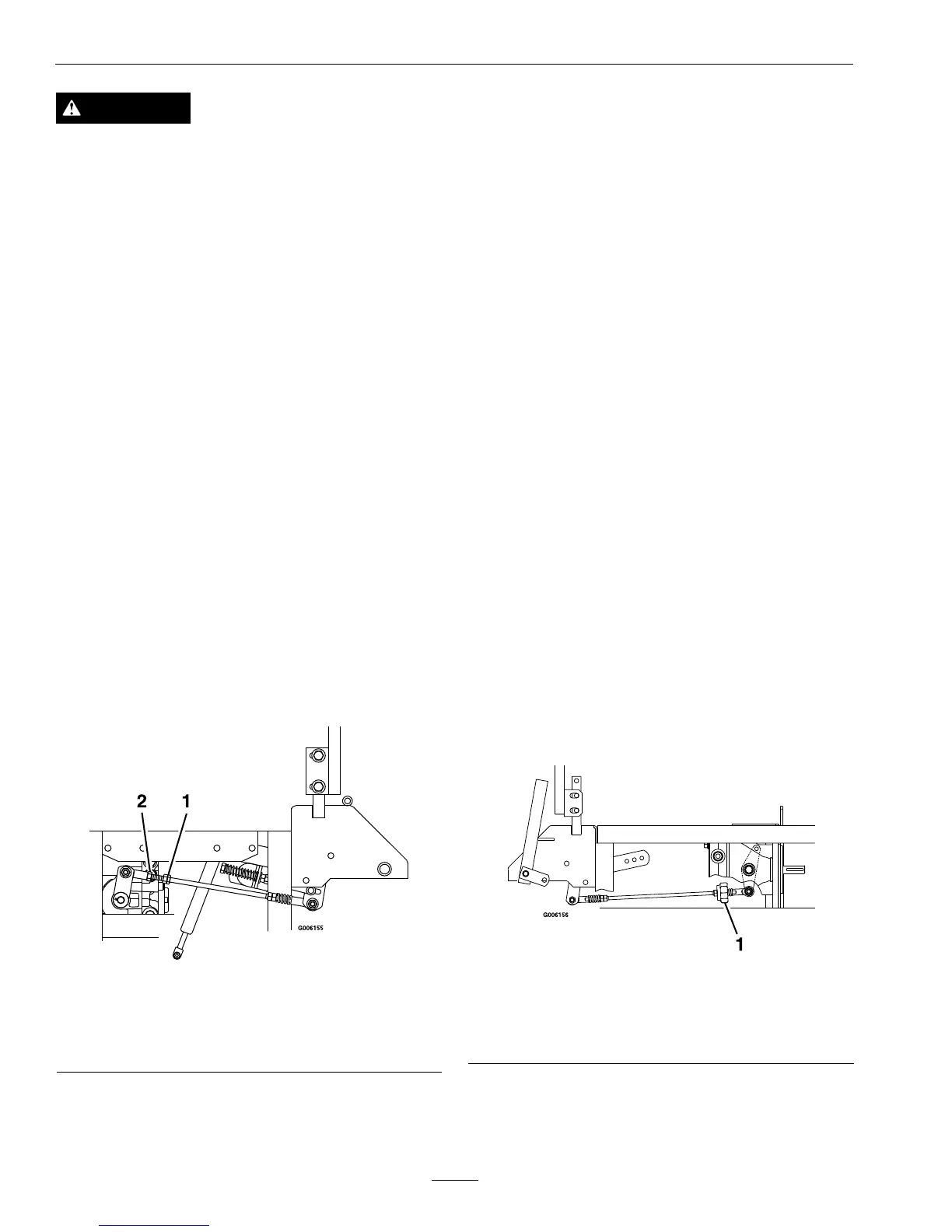

5.Loosenlocknutsfromtheballjointsateachend

ofthepumpcontrollinkage(

Figure28).

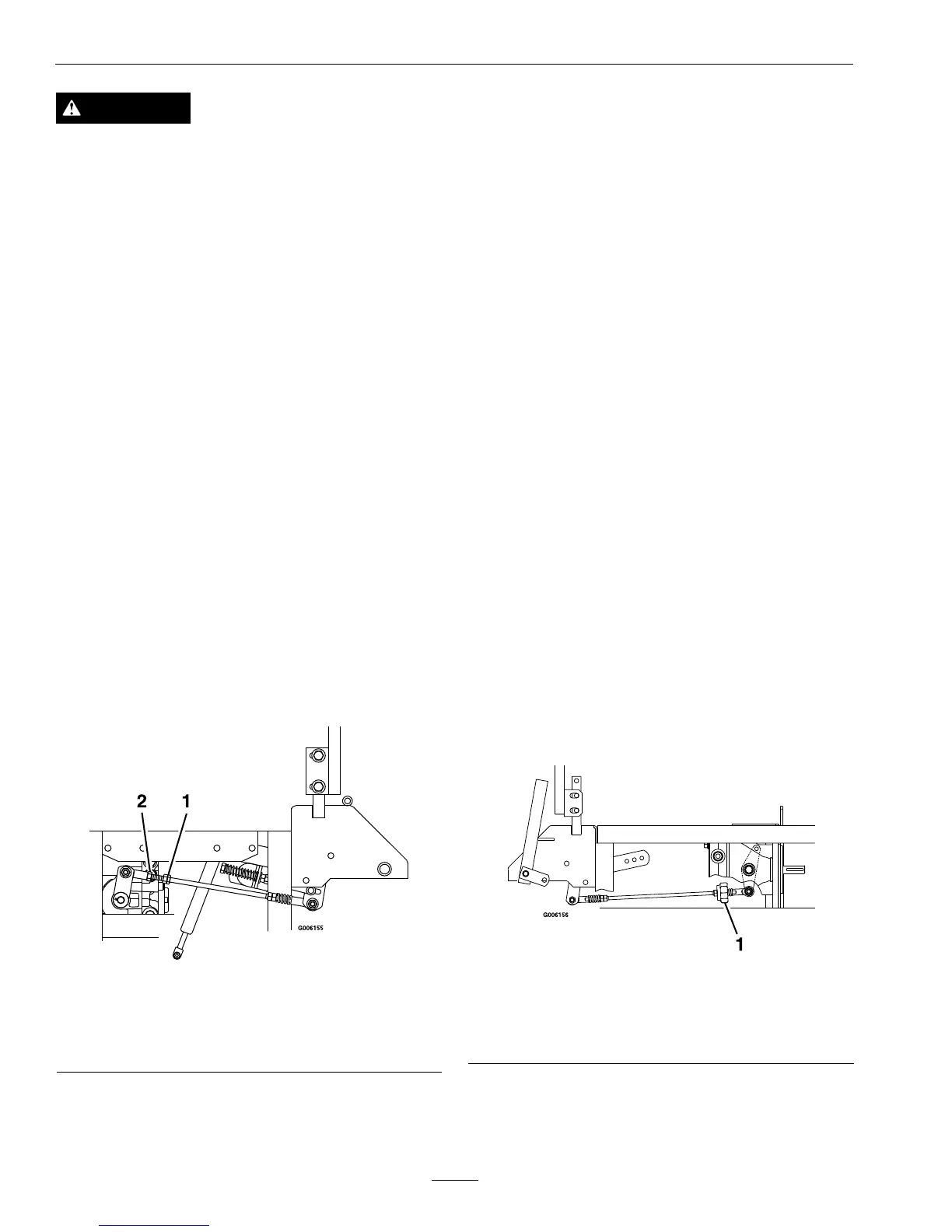

Figure28

Right-HandSideofUnit

1.Turnheretoadjust

2.Loosenhere(right-hand

thread)

6.Startengine.Brakemustbeengagedand

motioncontrolleversouttostartengine.

Operatordoesnothavetobeintheseat

becauseofthejumperwirebeingused.Run

engineatfullthrottleandreleasebrake.

7.Thereverseindicatorspringmustbecorrect

beforethefollowingadjustmentscanbemade.

SeetheReverseIndicatorAdjustmentsection.

Note:Themotioncontrolleverneedstobein

neutralwhilemakinganynecessaryadjustments.

Theleftrodassemblycontrolstheleftwheeland

therightrodassemblycontrolstherightwheel.

8.Bringthemotioncontrolleverintotheneutral

position.AdjustRHpumpcontrolrodlength

byrotatingthedoublenutsontherodinthe

appropriatedirectionuntilthewheelsslightly

creepinreverse(

Figure28).Movethemotion

controllevertothereversepositionandwhile

applyingslightpressuretotheleverallowthe

reverseindicatorspringtobringtheleversbackto

neutral.Thewheelmuststopturningorslightly

creepinreverse.Whenadjustmentiscomplete,

tightenlocknutsontoballjoints.

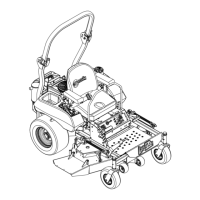

9.BringtheLHmotioncontrolleverintothe

neutralposition.AdjusttheLHpumpcontrolrod

lengthbyrotatingthetrackingadjustmentknobin

theappropriatedirectionuntilthewheelsslightly

creepinreverse.Movethemotioncontrollever

tothereversepositionandwhileapplyingslight

pressuretotheleverallowthereverseindicator

springtobringtheleversbacktoneutral.The

wheelmuststopturningorslightlycreepin

reverse(

Figure29).

Figure29

Left-HandSideofUnit

1.TurnLHtrackingadjustmentknob.(DoNotloosenany

nutsonLHside)

10.Shutoffunit.Removejumperwirefromwire

harnessconnectorandplugconnectorintoseat

switch.

46

Loading...

Loading...