Drain the oil sump to ensure that the oil does not syphon

out. Thoroughly clean the area around the pump body

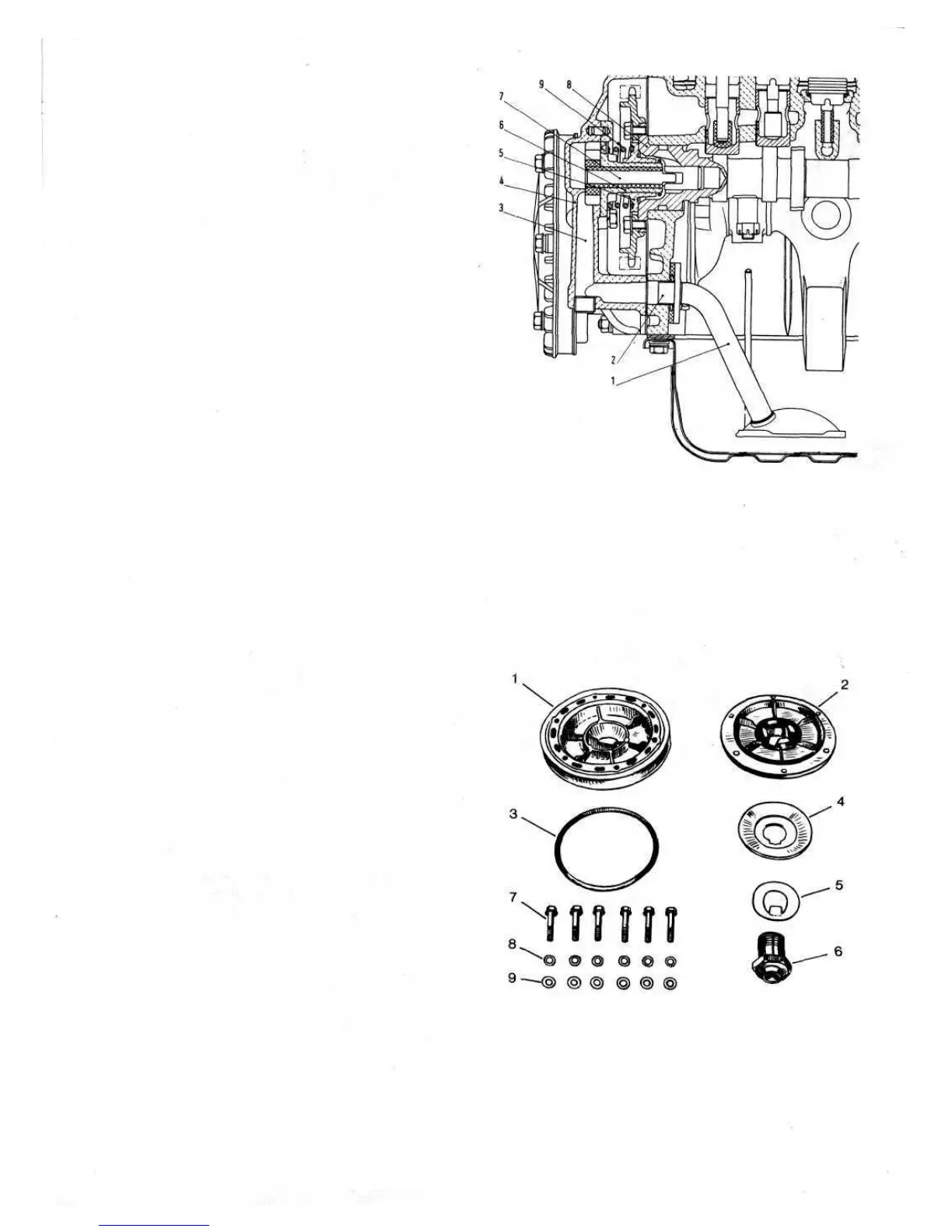

(see FIG 1 :37).

Remove the end cover plate by releasing the retaining

bolts and washers. Carefully ease the driven gear down-

wards followed by the driving gear and shaft

Clean all parts removed and blow clean using a com-

pressed air jet. Inspect the timing gear cover pump area

for cracks or distortion. Check that the inner duct for oil

delivery to the pump is clear of obstruction. If in doubt

remove the drain plug and filler cap and use a com-

pressed air jet to clean the passage.

Check the gear teeth for damage or excessive wear,

ensure that the drive gear is firmly attached to its spindle

and that the end cover plate is not badly scored or pitted.

Fit new parts as necessary.

Reassembly is the reverse procedure to dismantling,

taking care that all parts are assembled clean and the

end cover plate seating correctly with a new gasket.

5

4

3

2

1

1:14 Lubrication, oil filter, relief valve

Description :

The engine is pressure lubricated through a gear type

pump which is incorporated in the timing gear cover and

driven from the camshaft by dogs or gears. The lubrication

circuits are shown in FIGS 1 :36 and 1 : 37.

The pump draws oil from the sump through a suction

horn fitted with a filter screen which is fixed to the crank-

case by a duct in the timing gear cover. This

supplies oil

to the pump.

Oil passes from the camshaft rear seat onto the crank-

shaft rear support where it flows into an adjacent chamber.

From here the oil flows through ducts in the crankshaft

from end to the centrifugal oil filter. The centrifugal filter,

which also acts as a pulley for the generator and blower

drive, rotates with the crankshaft.

Oil from the filter enters a passage in the crankshaft,

where it lubricates the main and connecting rod bearings

and passes from a special groove in the front main

bearing and ducting in the crankcase into which is

inserted the oil pressure warning sender unit, and also

the delivery pipe for oil to the overhead valve gear.

The pushrod sleeves provide the return path for the oil

from the cylinder head and delivers oil to the tappet gear

and the camshaft cams. The tappets are suitably drilled

to allow correct circulation of the oil. The tappets are

located in two casting cavities, one of which com-

municates with the timing gear housing and the other

one to the crankshaft front drain support drain.

The oil pressure is regulated by a pressure relief valve 5

(see FIG 1 :38) mounted at the rear end of the camshaft.

It comprises a hubbed disc which slides on a guide 6 of

the oil pump drive shaft 7. Under spring load 9 the valve

disc circumferentially closes an annular chamber which

communicates with the lubrication circuit. Excessive oil

pressure causes the disc to uncover the chamber.

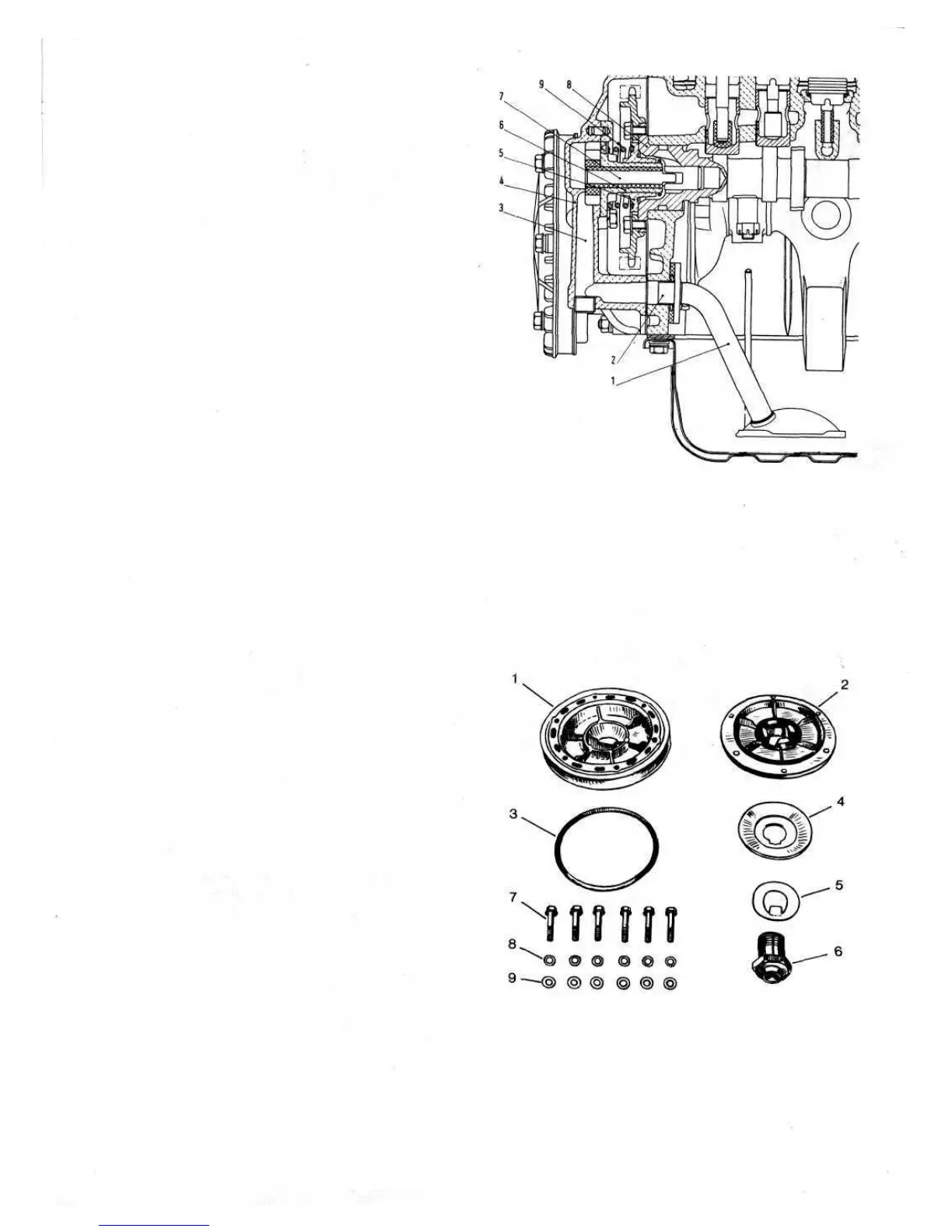

Centrifugal oil filter:

The oil filter is of the centrifugal type comprising of

two flanges and an oil slinger. The filter is attached to the

rear end of the crankshaft as shown in FIG 1 :38. The

outside diameter of the oil slinger (see FIG 1 :39) is

smaller in diameter than that of the flanges but of such a

F500

27

Key to Fig 1:39 1 Drive pulley 2 Rotor hub

3 Seal ring 4 Oil slinger 5 Lockplate

6 Hub-to-crankshaft hollow screw 7, 8, 9 Pulley-to-hub

mounting screws, toothed washers and plain washers

FIG 1:39 Centrifugal oil filter components

Key to Fig 1 :38 Suction scoop 2 Hole in crankcase

3 Duct in timing sprocket cover 4 Timing sprocket cover

5 Oil pressure relief valve 6 Drive shaft guide and oil

pump cover 7 Oil pump driving gear shaft 8 Camshaft

9 Oil pressure relief valve spring

FIG 1:38 Engine longitudinal section through oil pump

Loading...

Loading...