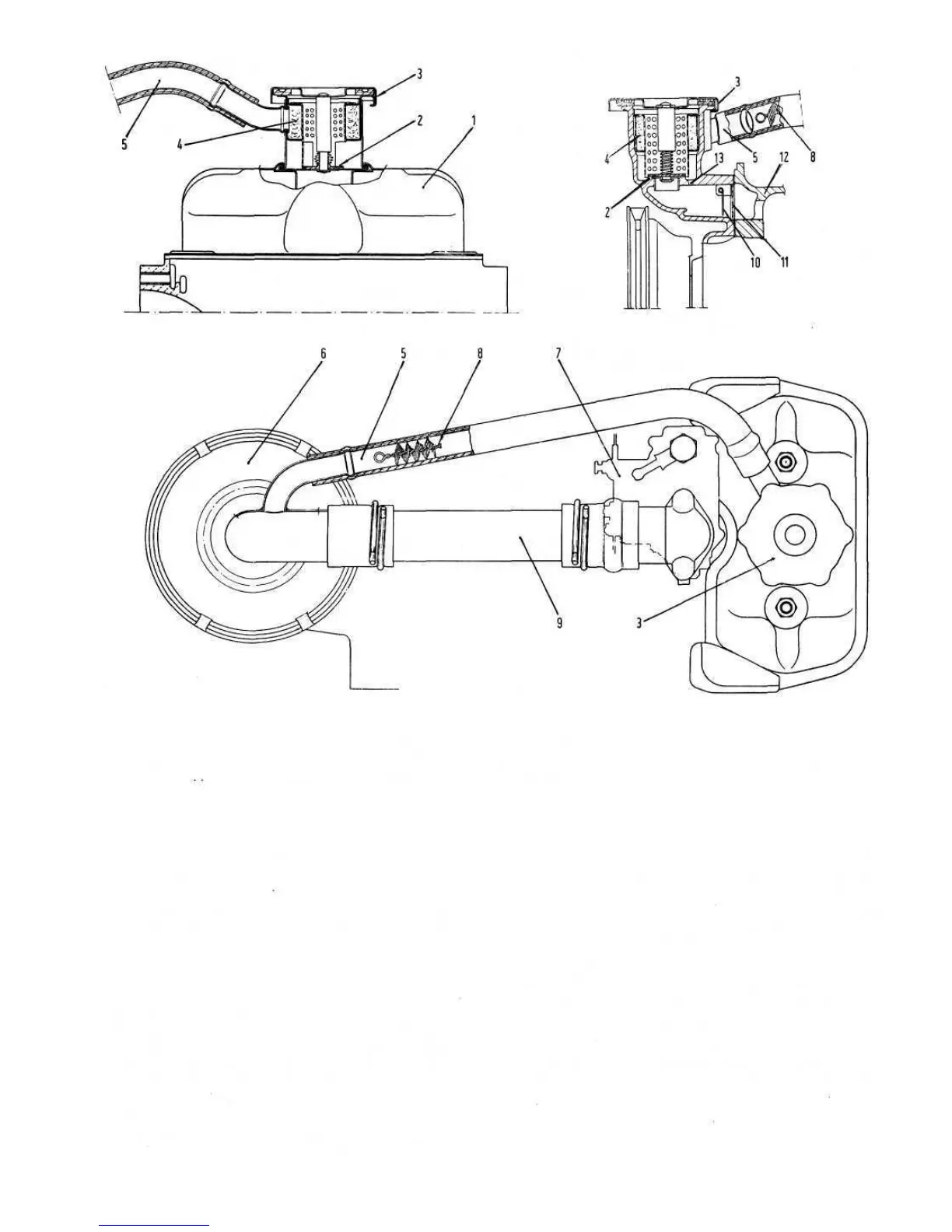

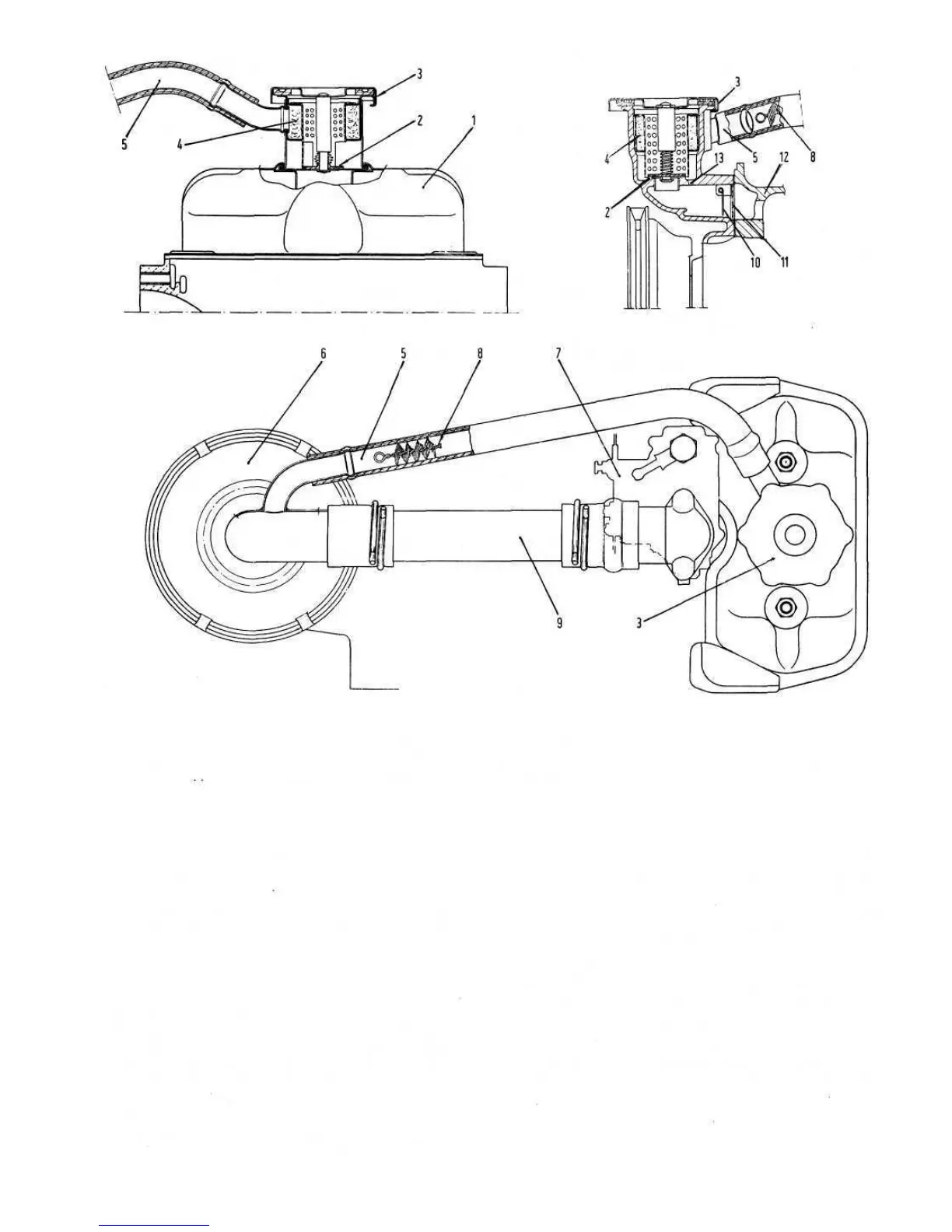

FIG 2:18 Diagram of blow-by gases re-circulation device

Key

to

Fig

2:18

1 Head cover 2 Blow-by gases and oil vapours breather valve 3 Oil filler cap

4 Strainer

9 Air suction pipe, air cleaner to carburetter

8 Flame trap

13 Exhaust duct

12 Crankcase

7 Carburetter6 Air cleaner

11 Filter gauze

10 Movable partition

5 Pipe

Engine 110 F. 000 Engine 120.000

designed to dampen the air intake noise and the carburet-

ter venturi hiss and is so located in the blower conveyor

system so that only clean dry air is drawn into the induc-

tion system.

To ensure complete protection of the engine it is

recommended that the air filter element be replaced every

6000 miles or even earlier if the vehicle is operating in

dusty conditions.

It should be noted that an oversize air cleaner may be

obtained if the vehicle is to be operated in very dusty areas.

Air cleaner—engine 110 F.000:

To remove the air cleaner element, disengage both the

spring hooks 2 as shown in FIG 2:17 and lift away the

cover 4 by turning it inwards together with the hose 5.

2:9 Air cleaner (sedan)

The pleated paper air cleaner element is contained in a

casing housed in a recess of one of the silencing chambers

provided in the blower conveyor as shown in FIG 2:16.

The air cleaner is connected to the carburetter by means of

a specially shaped hose. The silencing chamber is

44

For full instruction refer to Section 2 :6.

Carburetter cleaning:

See Section 2 :6 for full check details.

Throttle valve components:

Engine 110 F. 000

Loading...

Loading...