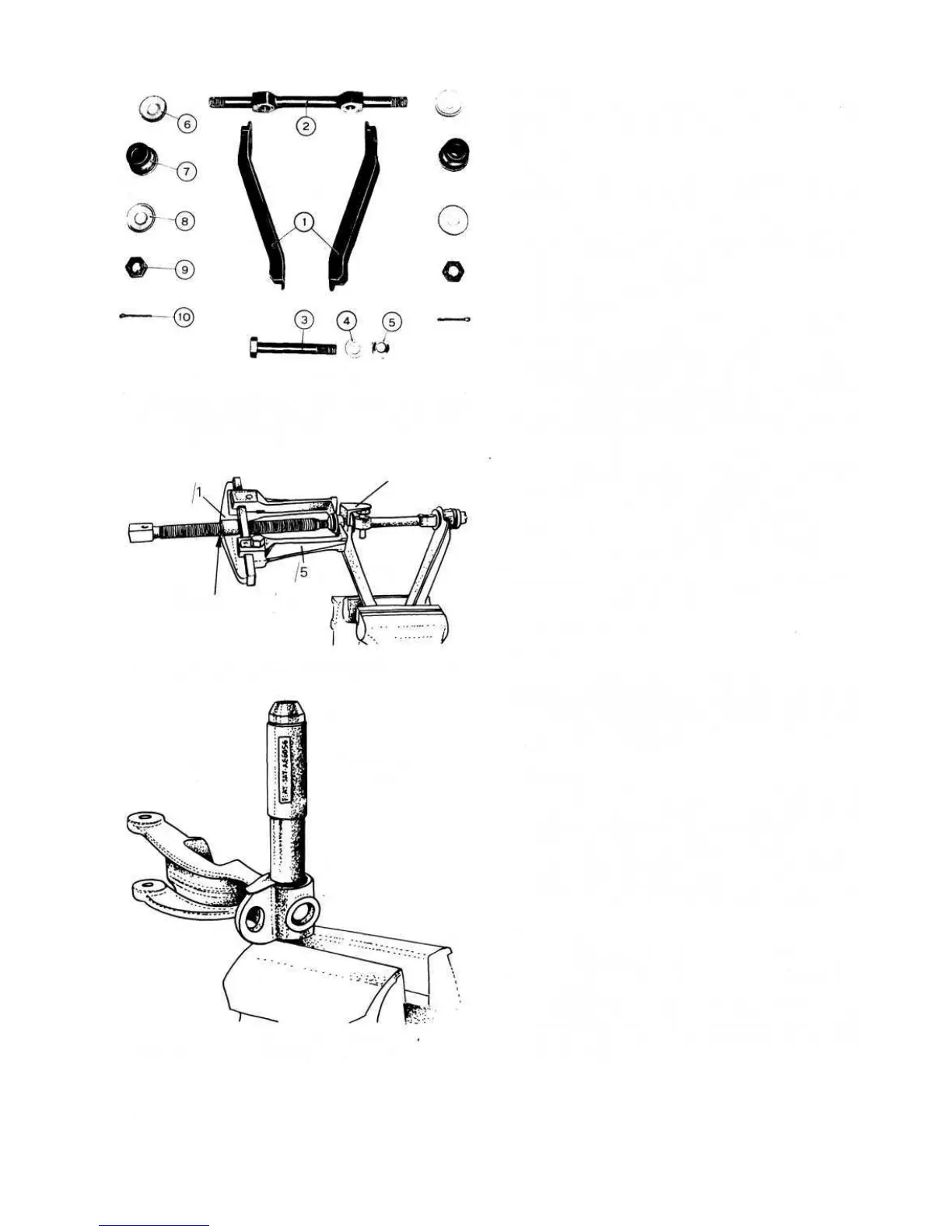

FIG 8:6 Swinging arm components

Key to Fig8:6 1 Half-arms 2 Pin, arm to body mounting

3 Pin, arm to kingpin housing mounting 4 and 5 Washer and

nut 6 and 8 Cups, rubber bushes 7 Rubber bushes

9 and 10 Sptitpins and nuts, mounting, pin (2) to arms

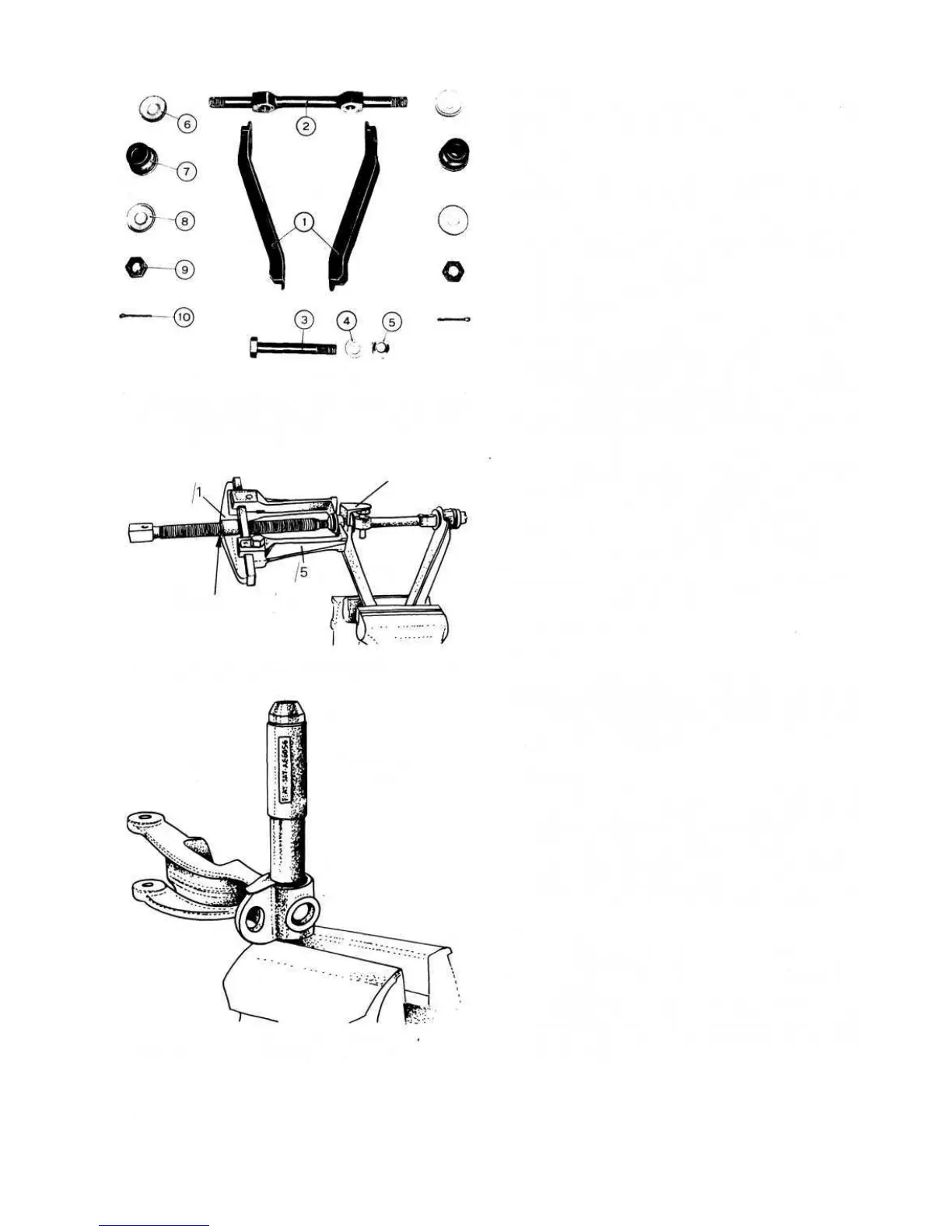

TOOL A.66054

PULLER A.40005/

FIG 8:7 Removal of rubber bushes by universal puller

A.40005 and arm retainer tool A.66054

DRIFT ROD

A.66056

FIG 8:8 Drift rod A.66056 for kingpin housing Estend-

block' removal and installation

90

Inspection:

Thoroughly clean the half arms and dry using a com-

pressed air jet. Then proceed as follows:

1 Thoroughly inspect the half arms to ensure that they

are not distorted or show signs of cracking which, if

evident, should be renewed. Compare the two half

arms to ensure that they have the same inclination and

that the holes are not elongated but are true and

properly aligned.

kingpin housings by 'estendblocks' which are fitted in the

main leaf eyes. A specially shaped rubber buffer is

mounted on the spring centre bolt.

Leaf spring inspection and repair:

To dismantle the leaf spring assembly remove the two

side clips and the centre bolt. Thoroughly wash all parts

and to inspect proceed as follows:

1 Inspect carefully to check that the leaves are not

broken or show signs of cracking which, if evident,

the leaf must be renewed. It should be noted that the

third spring leaf is not available as a service replace-

ment part which means that if this leaf is damaged the

whole spring must be renewed.

2 Check that there is no paint or underseal present

between the leaves which, if evident, must be removed.

3 Ensure that the mating surfaces of the leaves are

perfectly smooth and clean. If there are signs of

rusting or slight indentations, these areas must be

cleaned using a file. Any deep indentations will be a

source of weakness and the leaf must be renewed.

4 The 'estendblocks' are press fitted into the main leaf

eyes and must be thoroughly inspected for excessive

wear, signs of seizure and dry operation of the rubber

parts. The 'estendblocks' should be renewed if there

is any doubt as to their condition. To remove and

replace the 'estendblocks' use Fiat .drift A.66056 or a

suitably sized drift as shown in FIG 8 :8.

5 Check the condition of all rubber pads, the centre

buffer and the polyethylene linings for signs of wear,

cracking or splits and, if evident, new parts must be

fitted.

6 Once the spring has been reassembled it should be

tested by loading as shown in FIG 8 :5.

8:4 Swinging arms

Description:

The swinging arms comprise two pressed steel sheet

half arms which are joined by two pins, one on the

kingpin housing and the other on the body (see FIG

8:6). Rubber bushes ('flanblocks') are press fitted into

the half arms for the attachment of the swinging arm pin

to the body as shown in FIG 8 :6.

Dismantling:

1 Clamp the swinging arm into a vice and fit Fiat tool

A.66054 as shown in FIG 8:7. Remove the splitpin

and nut securing the half arms onto their pin.

2 Using a universal two leg puller or Fiat puller A.40005

together with items 1 and 5 pull out the rubber bushes

as shown in FIG 8:7. Remove tool A.66054 insert it

on the other half arm and repeat the operation

performed for the bush removal on the first arm.

Loading...

Loading...