39

38

28 29 30

A

31

32 33

28 29 30 3.1

B

28

29 30 31

C

34

34

34

37363523

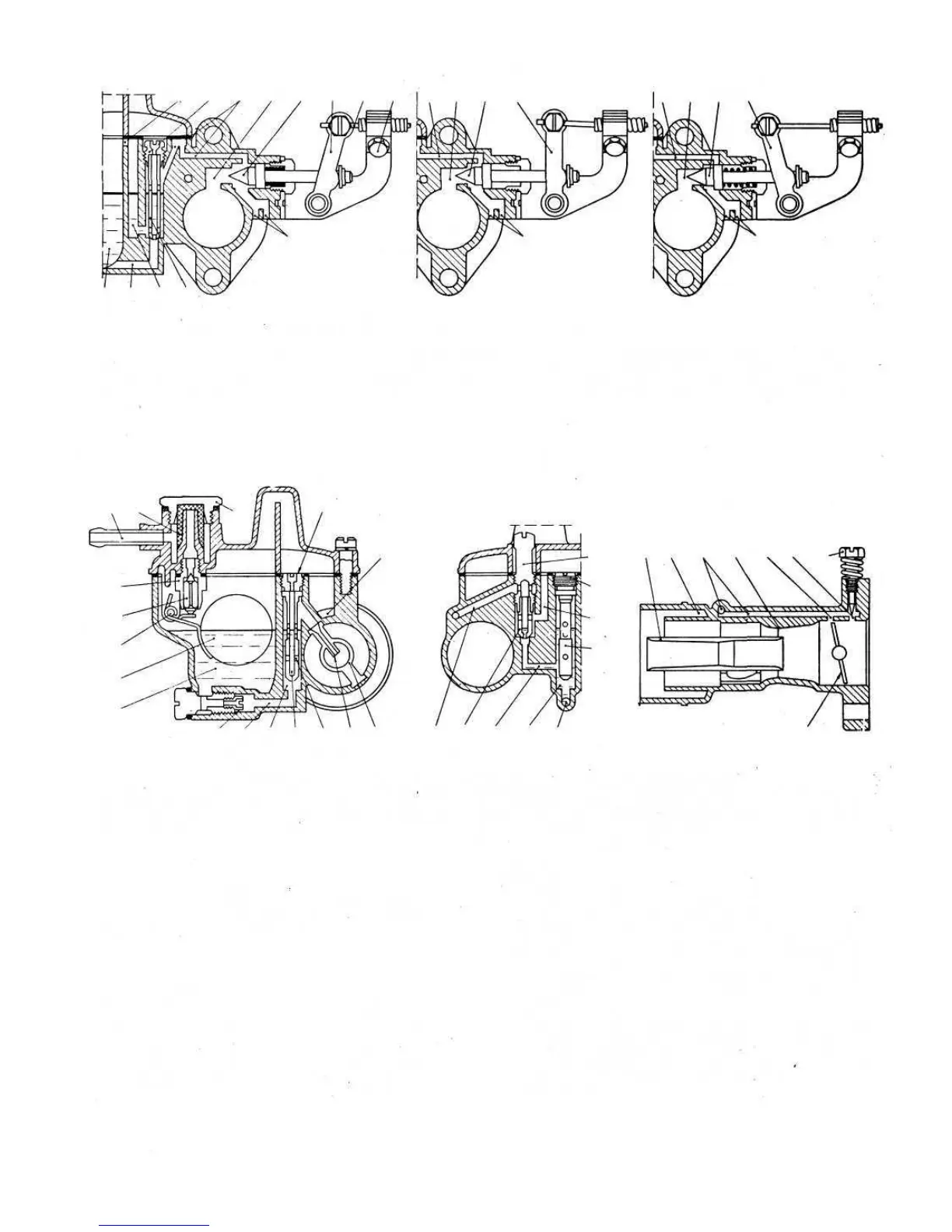

FIG 2:13 Diagrammatic section views of 26.OC Weber carburetter through the starting device

1

2

.3

4

5

27

26.

25,

24.

23.

22

16

17

8

21

20

9

_6

.4

7

.8

10 19 18

17

16 1 5

95

10

11

12

13

14.

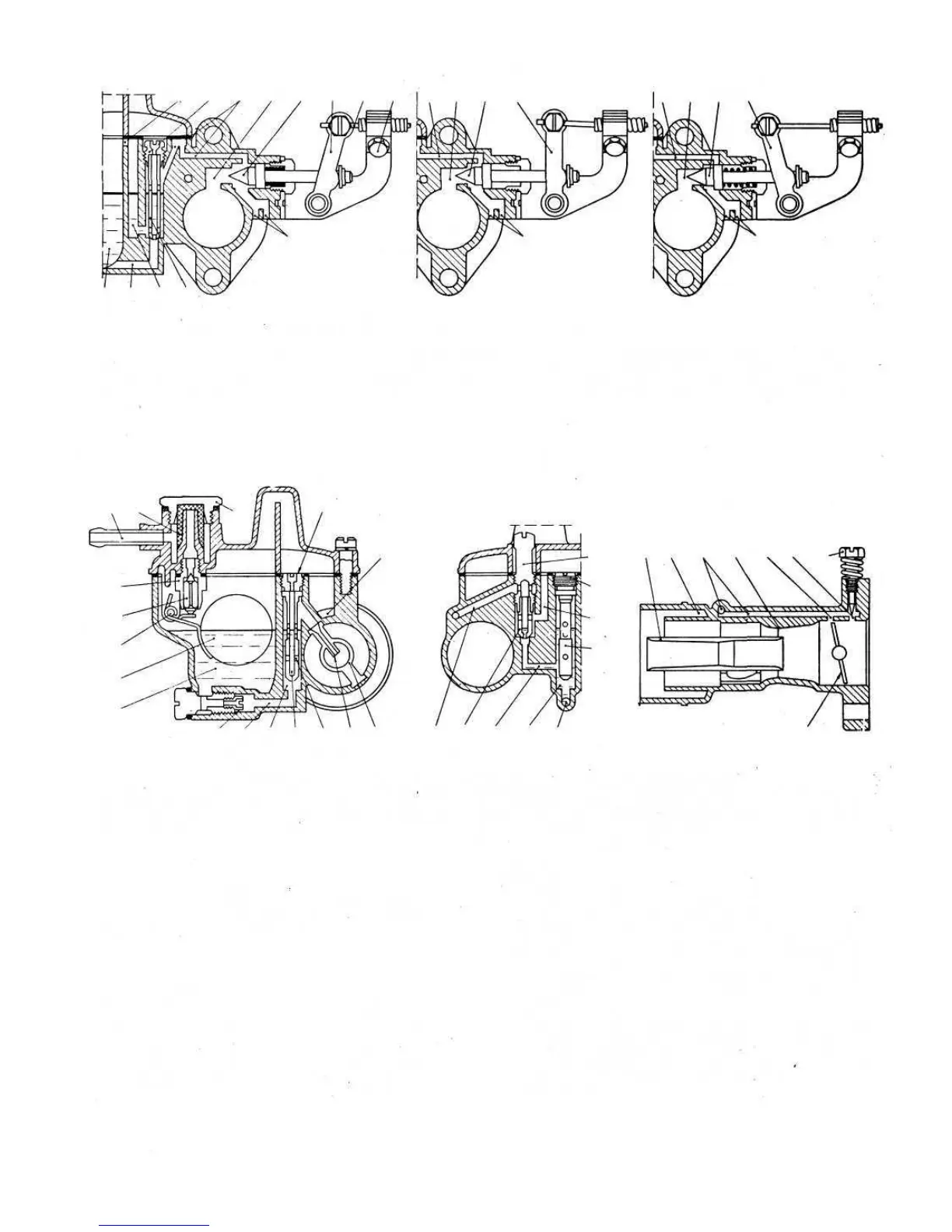

FIG 2 :14 Diagrammatic section views of 26.OC Weber carburetter

Key to Fig 2:14 1 Fuel inlet connection 2 Filter gauze 3 Filter inspection plug 4 Air corrector jet

5 Air intake 6 Idle speed jet holder 7 Idle airduct 8 Emulsion tube 9 Secondary venturi 10 Idle mixture duct

11 Primary venturi 12 Progression hole 13 Idle orifice to duct 14 Idle mixture adjustment screw 15 Throttle

16 Bowl-to-well duct 17 Emulsion tube housing well 18 Well-to-idle jet duct 19 Idle speed jet 20 Nozzle

21 Emulsion orifices 22 Main jet 23 Bowl 24 Float 25 Float pivot 26 Valve needle 27 Needle valve

When the starting device is not in operation valve 30

covers the hole 29 so preventing the passage of mixture as

shown in diagram 'C (FIG 2:13).

Engine starting:

So that full advantage may be taken of the progressive

action starting device the engine should be started as

follows:

1 Cold starts. The starting device should be moved

across to position 'A' as shown in FIG 2:13. Once the

engine has fired push the control in partially.

42

2 Warm starts. Only partially move the starting device

to position 'B' as shown in FIG 2:13.

3 Engine warm-up. As the engine begins to warm up to

its normal operating temperature. Gradually push home

the starting device lever so as only to supply the engine

with the richened charge enabling the cold engine.

operation to be smooth and regular. Position 'B'shown

in FIG 2:13.

4 Normal car driving. Once the engine has reached its

normal operating temperature the starting device

should be completely brought out of operation by

bringing the control lever to the position C shown in

FIG 2:13.

Key to Fig 2:13

23 Bowl 28 Starting mixture duct

29 Starting mixture duct

30 Starting valve

34 Emulsion air orifices

38 Starting air corrector screw

C Choke disengaged

B Choke partially inserted

37 Starting jet

33 Bowden fixing screw

A Choke fully inserted

36 Starting reserve well

32 Starting device control wire

31 Starting device control lever

35 Bowl-to-starting jet duct

39 Reserve well emulsion air slot

Loading...

Loading...