1

2

6

3

8

11

13

17

19

22

25

27

29

31

33

36

35

32

34

30

28

26

24

23

21

20

,18

16

15

14

12

10

.9

.1

5

4

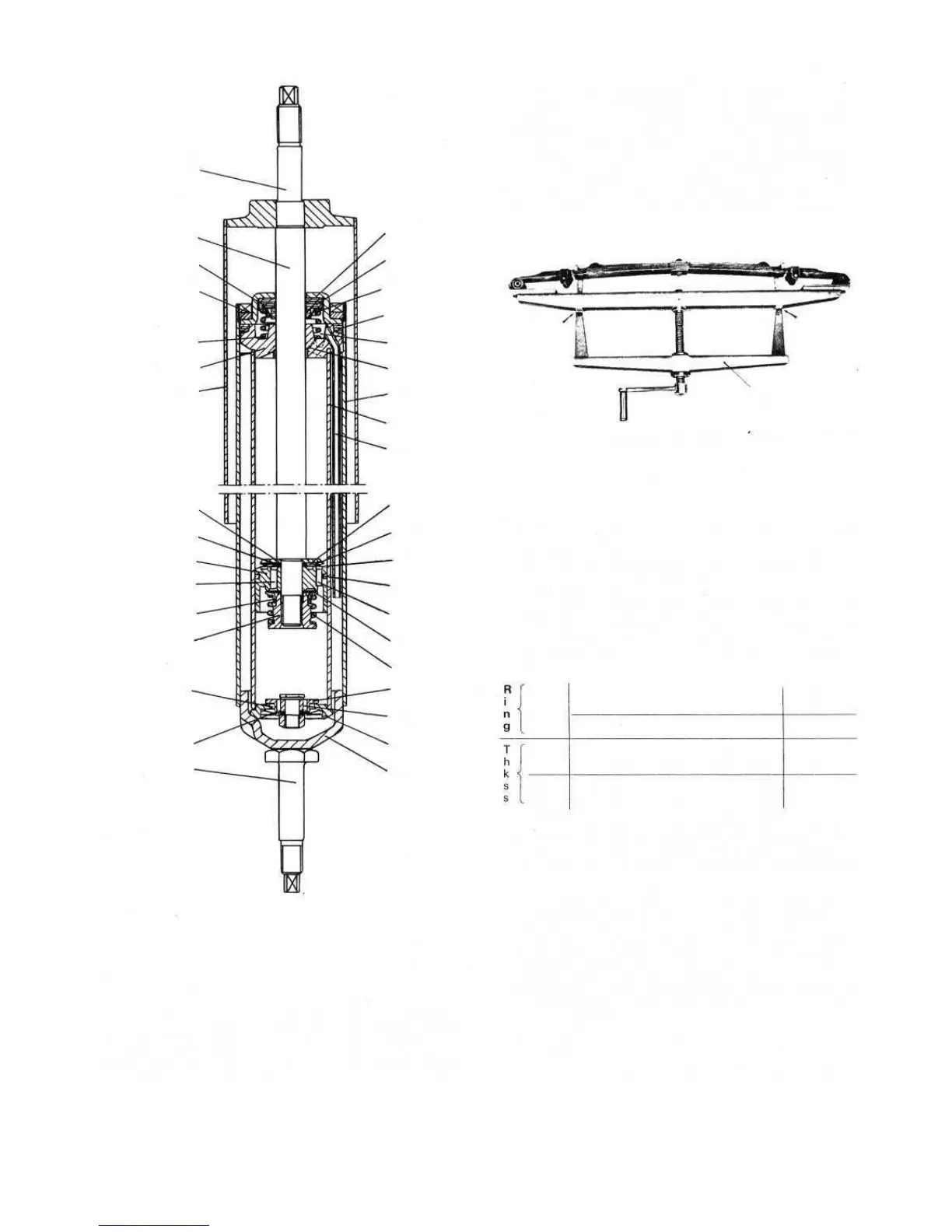

FIG 8:11 Sectional view of shock absorber

Key to Fig 8:11 1 Threaded shank, floor mounting

2 Rod 3 Cylinder upper blanking threaded ring

4 Seal housing 5 Rod seal 6 Tab spring 7 Spring cup

8 Gasket packing spring 9 Casing gasket 10 Vapour

pocket drain and chamber 11 Rod guide bush

12 Vapour pocket drain capillary hole 13 Dust shield

92

14 Casing 15 Working cylinder 16 Vapour pocket drain

passage 17 Valve lift limiting disc 18 Fluid passage orifice

19 Valve lift adjustment washer 20 Valve star-shaped spring

21 Inlet valve 22 Piston 23 Compression ring

24 Inlet valve holes in piston 25 Rebound valve holes

in piston 26 Rebound valve 27 Valve guide cup

28 Rebound valve spring 29 Piston mounting plug

30 Compensating valve 31 Compensating valve annular

passage 32 Compensating-and-compression valve carrier

plug 33 Compression valve 34 Compression valve orifices

35 Lower plug 36 Threaded shank, lower mounting

FIXTURE

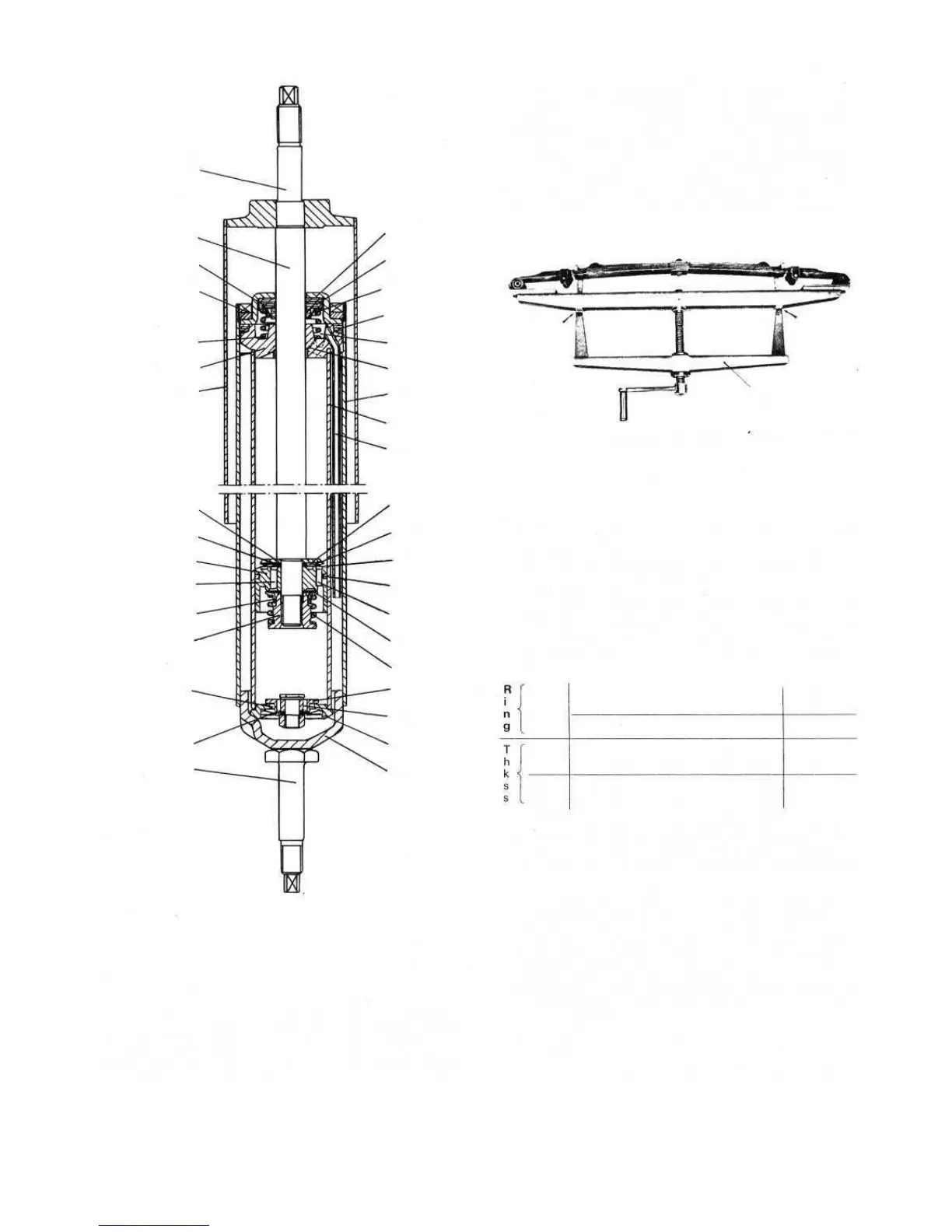

FIG 8:12 Leaf spring position under full static loads'

on fixture A.66061 or A.74061

no signs of distortion or cracking which, if evident,

new parts must be fitted.

2 Check the steering knuckle surfaces, that are in con-

tact with the bearing inner races for any signs of

scoring or seizure.

3 Inspect the condition of the two upper thrust rings and

of the lower packing ring. Parts which show sign of

excessive wear must be renewed. Lower packing rings

are supplied in service in the thicknesses tabulated

below.

Once the items have been reassembled no appreciable

clearance should be evident between the steering

knuckle and the kingpin housing. This adjustment

is obtained by installing the lower packing ring of

suitable size.

4 Check that the seating on the drums for the roller

bearing outer races are smooth as no clearance is

allowable between the races and their seatings. Care-

fully inspect that the bearing cages and the rollers

show no signs of chipping, breakage, or discolouration

due to overheating.

5 Carefully inspect the seal which must not be torn and it

should locate perfectly both on the drum and the

steering knuckles.

Reassembly:

Reassembly is the reverse procedure to dismantling.

Oversizes

Under-

sizes

.002 .004 .006 .008 .010 .012

.0979 .1016 .1036 .1056 .1076 .1095

.100 .102 .104 .106 .108 .110

.002 .004

.0957 .0938

.096 .094

Stand.

in.

in.

.0977

in.

.098

Loading...

Loading...