Instruction Manual

D103412X012

Principle of Operation

July 2013

259

Appendix A Principle of OperationA‐A‐

Digital Valve Controller Operation

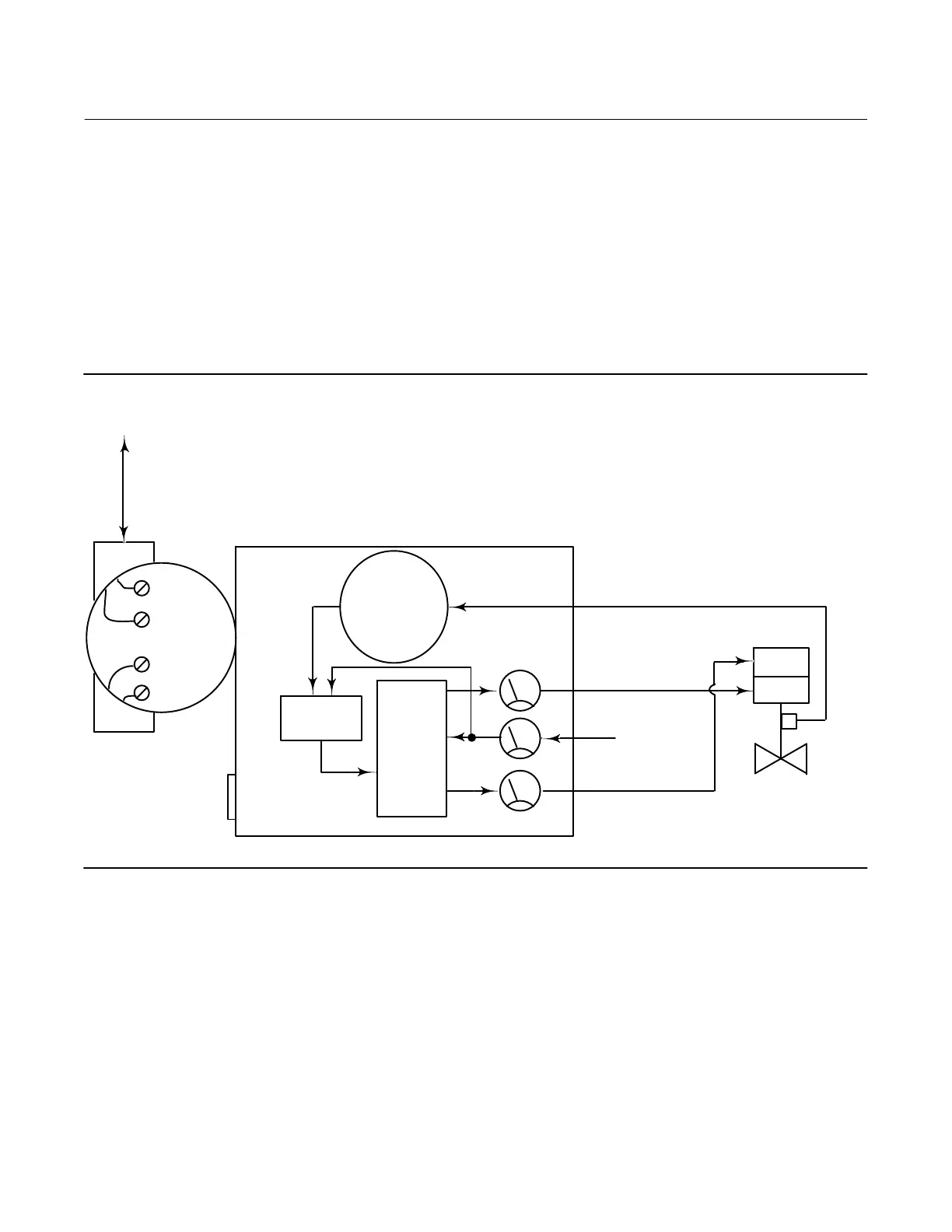

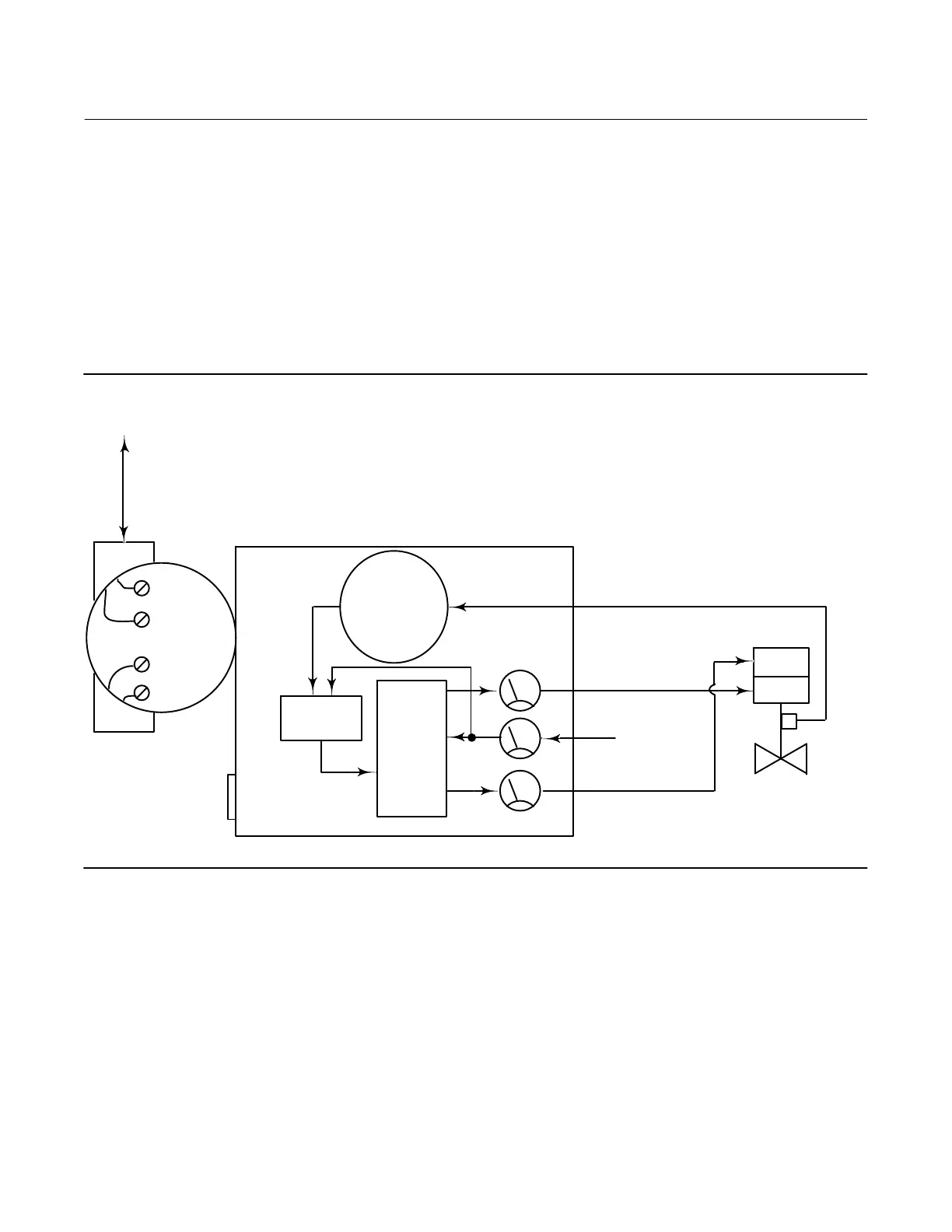

The DVC6200f digital valve controller has a single module base that may be easily replaced in the field without

disconnecting field wiring or tubing. The master module contains the following submodules: current‐to‐pneumatic

(I/P) converter, printed wiring board assembly, and pneumatic relay. The relay position is detected by sensing the

magnet on the relay beam via a detector on the printed wiring board. This sensor is used for the minor loop feedback

(MLFB) reading. The master module can be rebuilt by replacing the submodules. See figures A‐1 and A‐2.

Figure A‐1. FIELDVUE DVC6200f Digital Valve Controller Block Diagram

E1376

DIGITAL

SETPOINT

9–32 VOLT

FIELDBUS

SUPPLY

PRESSURE

PRINTED

WIRING BOARD

PNEUMATIC

RELAY

I/P

CONVERTER

OUTPUT A

OUTPUT B

VALVE TRAVEL FEEDBACK

AUXILIARY

TERMINALS

TERMINAL BOX

DRIVE

SIGNAL

VALVE AND

ACTUATOR

VENT

The DVC6200f digital valve controller is a bus‐powered instrument that provides a control valve position in response

to a digital setpoint from the control room. The following describes a direct acting DVC6200f digital valve controller

mounted on a sliding-stem piston actuator, where the valve is closed with zero power to the instrument.

The setpoint is routed into the terminal box through a single pair of wires and then to the printed wiring board

assembly submodule where it is read by the microprocessor, processed by a digital algorithm, and converted into an

analog I/P drive signal.

Loading...

Loading...