Multi-DENCO Commissioning

FläktGroup DC-2013-0101-GB • Subject to modifications • R5-08/2020 101

2

nd

and 3

rd

vacuum

• Shut off the vacuum pump and add oxygen free nitrogen to a system pressure of

1bar.

• Safely release the gas to just above atmospheric pressure

• Evacuate the system to at least 2 Torr (2.6 mbar)

• Again, shut off the vacuum pump and add oxygen free nitrogen to a system pressure

of 1 bar

• Safely release the gas to just above atmospheric pressure and once again evacuate

the system to at least 2 Torr (2.6 mbar)

• Once achieved, turn the vacuum pump off and observe that the system maintains a

vacuum for at least 30 minutes to prove the tightness of the circuit.

• On completion of evacuation, the gauge manifold should be closed off and isolated

from the vacuum pump, then connected to a refrigerant cylinder, the gauge lines

should be carefully purged of any air.

NOTE!

Multi-DENCO units can contain two different types of compressors – each with their

own oil type. Please follow the below recommendations:

Size 010 - 065

FV50S

Emkarate RL68H

Mobil Arctic EAL68

Size 092 - 130

POE 160SZ

Emkarate RL32H

Alternative oils are compatible with the original oil type used, therefore these can

be mixed and alternatives can be used as "top up".

For X-Version & H-Version units, refer to the separate condensing unit installation

manual for compatible oil types.

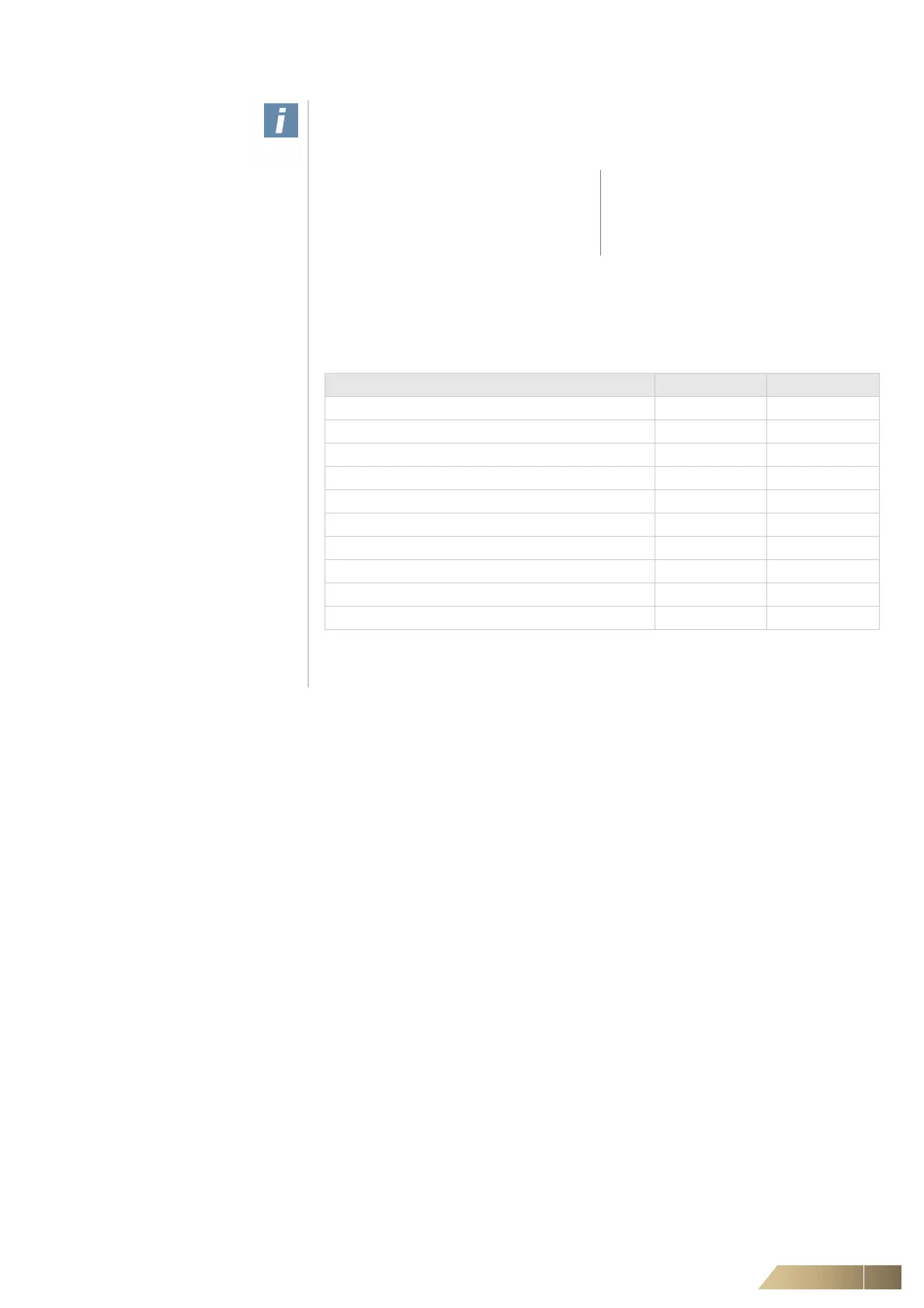

Emkarate Typical Properties

Tab. 8-1

Property and Procedure RL32H RL68H

Viscosity @ 40°C (cSt), ASTM D-445 33.7 72.3

Viscosity @ 100°C (cSt), ASTM D-445 5.9 9.8

Typical SUS Viscosity @ 100°F 150 300

Viscosity Index, ASTM D-2270 110 120

Pour Point (°C), ASTM D-97 -46 -39

Density @ 20°C (g/ml), ASTM D-1298 0.977 0.977

Flash Point (COC) (°C), ASTM D-92 270 270

Acid Value (mgKOH/g), ASTM D-974 modified 0.02 <0.02

Water Content (ppm), ASTM E 1064-85 <50 <50

Refractive Index @ 28°C 1.4530 1.4557

Loading...

Loading...