Multi-DENCO Servicing and Maintenance

FläktGroup DC-2013-0101-GB • Subject to modifications • R5-08/2020 119

1

The equipment should be thoroughly tested to ensure there are no refrigerant leaks to comply with EN 378-4

Associated equipment should also be service in accordance with manufacturer's specifications.

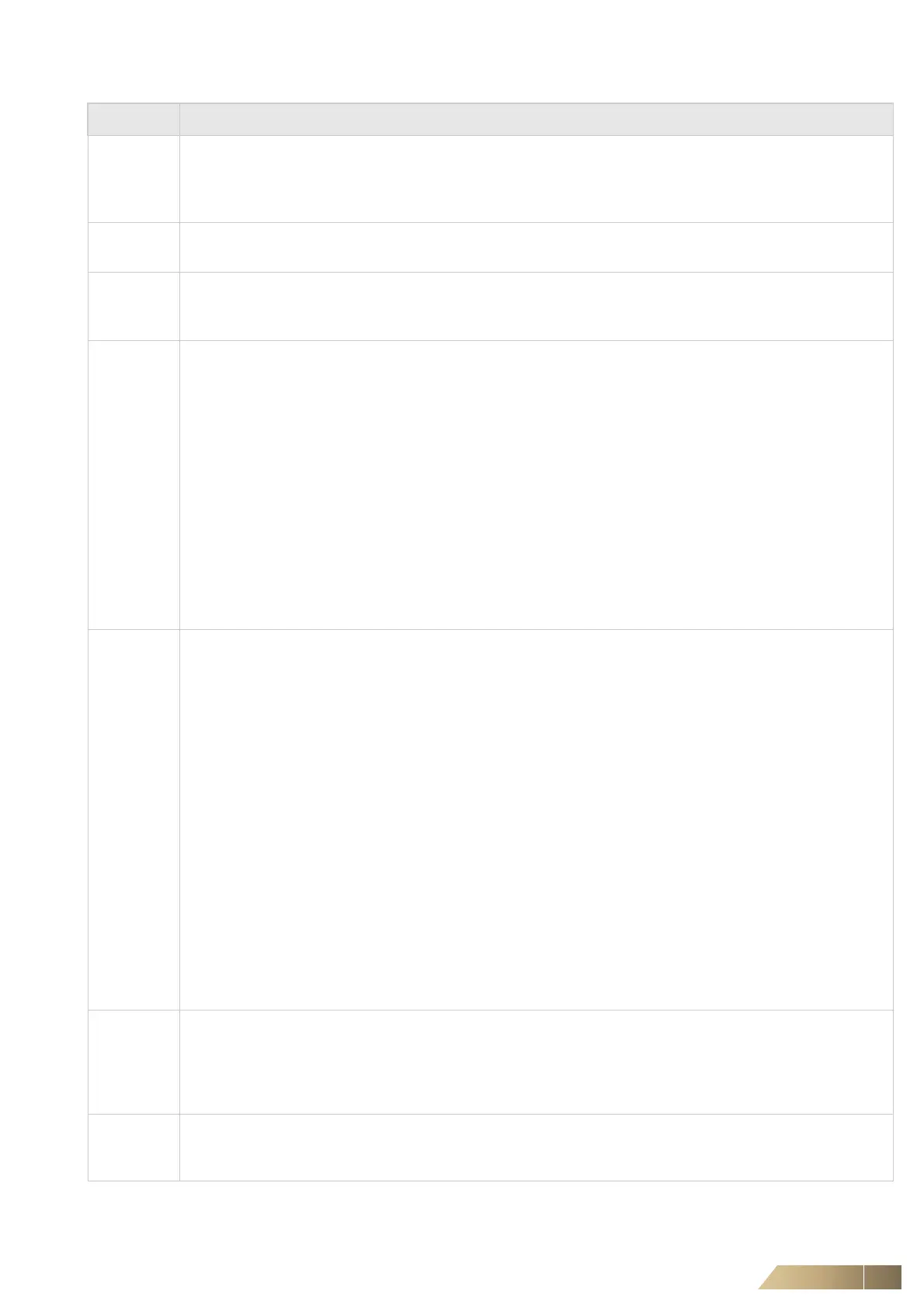

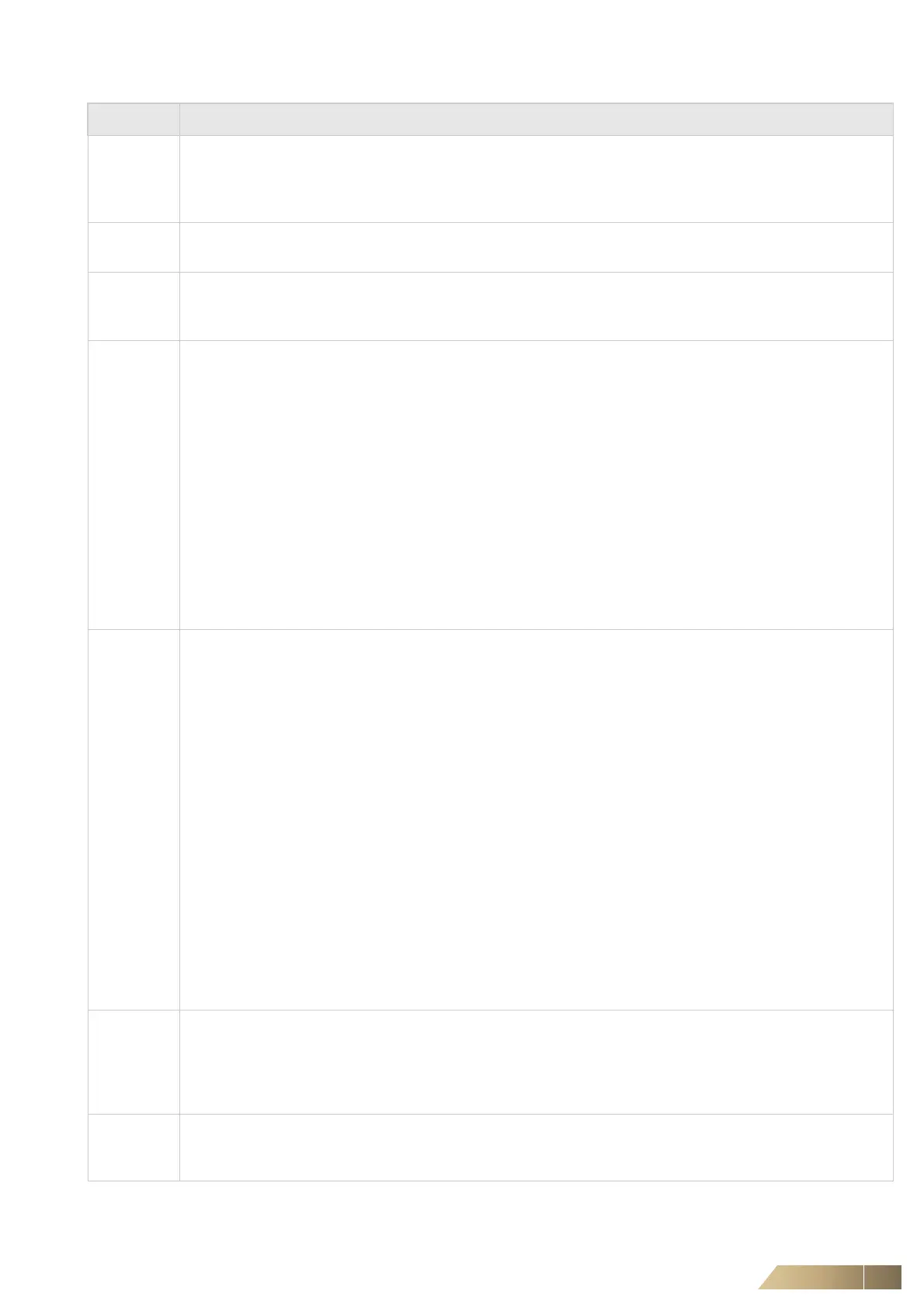

Interval Action

Daily

1: Check for any outstanding alarms.

2: Check display for good operation.

3: Visual inspection of exterior condition of the unit.

4: Visual inspection in and around the unit for the presence of liquids, which may show signs of a leak.

Weekly

1: Inspect outdoor heat exchanger for freedom of airflow.

2: Inspect gaskets, leaks, insulation, fan bearings and water drain of the unit, pay attention for any unusual noises.

Monthly

1: Check cleanliness of filters – inspect for break up and suitable sealing. Replace if necessary.

2: (If fitted) check cleanliness of grilles.

3: Check cleanliness both inside and outside of the unit.

Every

Three

Months

1: Check that the evaporating and condensing pressures are acceptable.

2: Check safety protection features, such as low pressure and temperature alarms, operate correctly.

3: Check capacity control for correct operation and configuration.

4: Check electrical connections for tightness. Repair or replace all damaged terminals.

5: Check all component electrical currents are within acceptable limits.

6: Check refrigerant sight glass.

7: Check condensate drain for free flow and drainage.

8: Check for refrigerant leaks

1

: Inspect all accessible refrigeration pipework with an electronic leak detector paying

particular attention to flexible tubes, capillary tubes etc. Check all accessible pipework fixings for tightness and security.

9: Inspect oil charges and levels to identify any loss since last inspection – rectify as necessary.

10: Inspect fan touch protection devices for compliance and functionality.

11: Check operation of on-board electrode steam boiler humidifier (if fitted): Check drain down and fill function,

disposal pumps and bottle current. Replace any expired bottles.

12: Check function of EC water pump (F-Version & P-Version).

13: Visual inspection of expansion vessel (F-Version & P-Version).

Every

Six

Months

1: Check contactors for damage or eroding.

2: Check that the electrical contactor overloads functions are set correctly.

3: Check any crankcase heaters (if fitted) for correct operation.

4: Check the evaporator fans can rotate freely.

5: Check conditions of evaporator coils and clean as required. Inspect heat exchangers for free airflow, cleaned

and combed where necessary.

6: If not conducted within the last 6 months; change air filters.

7: Check colour code of sight glass moisture indicator.

8: Check compressors for smooth operation.

9: Check anti-vibration mountings (outdoor unit) for damage.

10: Check pipework and insulation for damage (indoor, outdoor and interconnecting pipework).

11: The glycol content should be checked (if applicable) then adjusted and recorded as necessary (water-based circuits).

12: Check the condition of the water pipework, water volume flow, valve operation, and the cleanliness of all the

strainers (water-based circuits).

13: Check the calibration and functionality of the unit controller.

14: Check casing and connected ducting for any air leakage – repair where required.

15: Check room conditions required and adjust unit settings as necessary.

16: Clean unit inside and out with vacuum cleaner and wipe down with moist cloth.

17: Check proper function of the refrigerant leakage detection system (if fitted) either through use of a service tool

or use of testing refrigerant.

Yearly

1: Test the high pressure safety switch cut out and adjust/replace as necessary (see chapter 8.3.5

'Commissioning

refrigerant circuits

' on page 103).

2: Check for blockage in water strainers and act if required.

3: Check water pressures in FreeCool circuit.

4: (If fitted) Check tightness and for leaks in and around any pressure relief valves

After 5

Years of

Operation

1: (If fitted) it is recommended that the pressure relief valve is replaced.

Tab. 10-1

Loading...

Loading...