PRO PAK’R User Manual Version 1.0 Page -23-

FP InternationalFP International

3 operAting instructions

3.7 repAir And mAintenAnce

Preventive maintenance.

The machine should be serviced every half year of particular importance are:

• Internal cleaning, external cleaning, visual check of wear parts.

Repairs may only be carried out by qualied service personnel of FP International. The

following parts can be carried out by maintenance personnel of the costumers:

Replacing blade, replacing cone tip, replacing wear strips, cleaning / replacing backing wheel.

3.7.1 replAcing blAdes / cone tip

3.7.1.1 Change Cone Tip. (See page 14)

Pull the cone off the blow pipe and replace a new cone tip.

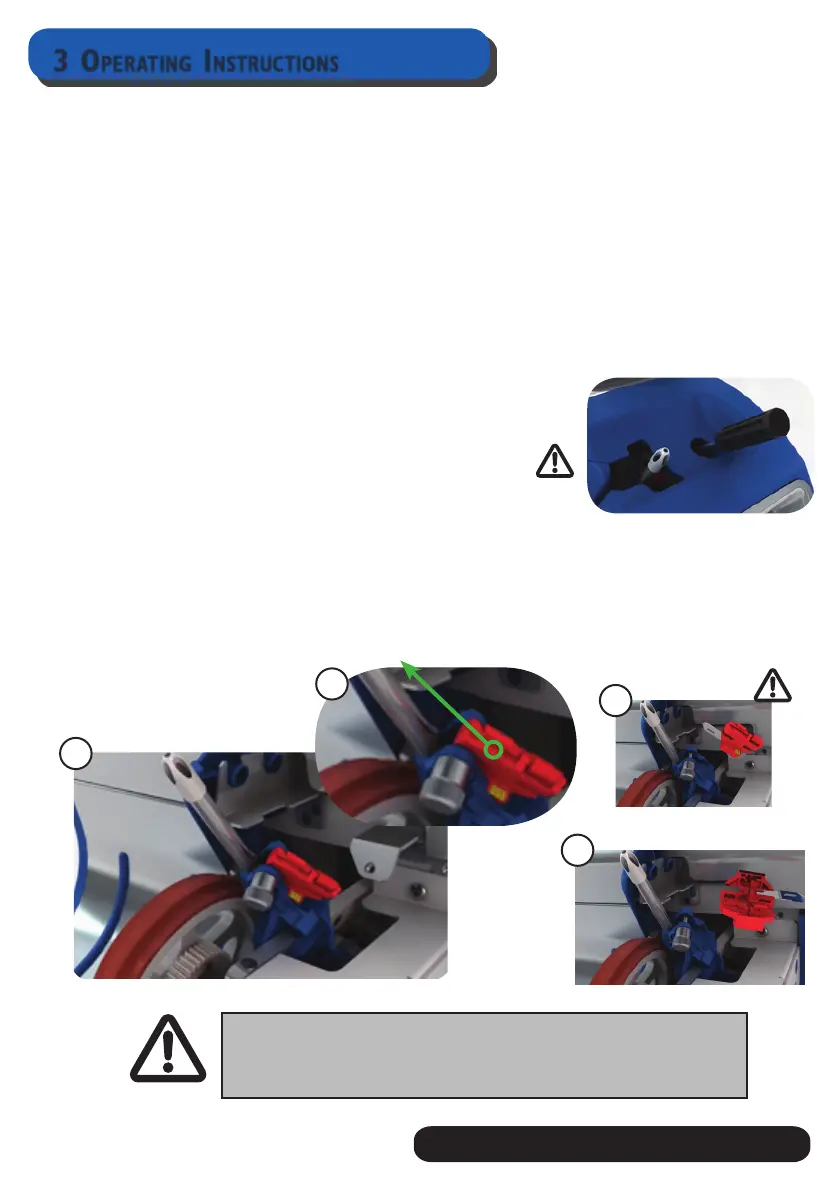

3.7.1.2 Replace blade or new cutting edge. (Be carefull, blade is

sharp.)

• If the lm jams frequently.

• After 100 lm rolls have been processed.

• If the blade is not cutting the lm properly or is making a

very rough cut.

Turn power OFF, unplug power cord, then wait 10 minutes for the machine to cool down.

Open display cover with slotted or Phillips screwdriver.

Unlock black screw. Slide the red bladeholder to the lltube (2), not possible to move the

bladeholder further, please rotate the blade (3 and 4). When the blade is dull on both sides,

please renew the blade.

1

2

3

4

RISK OF BURN

Before opening covers, turn power OFF, unplug power

cord, and wait 10 minutes for seal wheel to cool.

Loading...

Loading...