2

Turn the adjusting dial until the desired value is reached

-

power source is ready for welding

The maximum HotStart current is limited as follows:

-

Ignis 150 to 160 A

-

Ignis 180 to 200 A

Examples (set welding current = 100 A):

100 % = 100 A starting current = function deactivated

80 % = 80 A starting current = SoftStart

135 % = 135 A starting current = HotStart

200 % = 160 A starting current on Ignis 150 = HotStart, maximum current

limit is reached!

200 % = 200 A starting current on Ignis 180 = HotStart

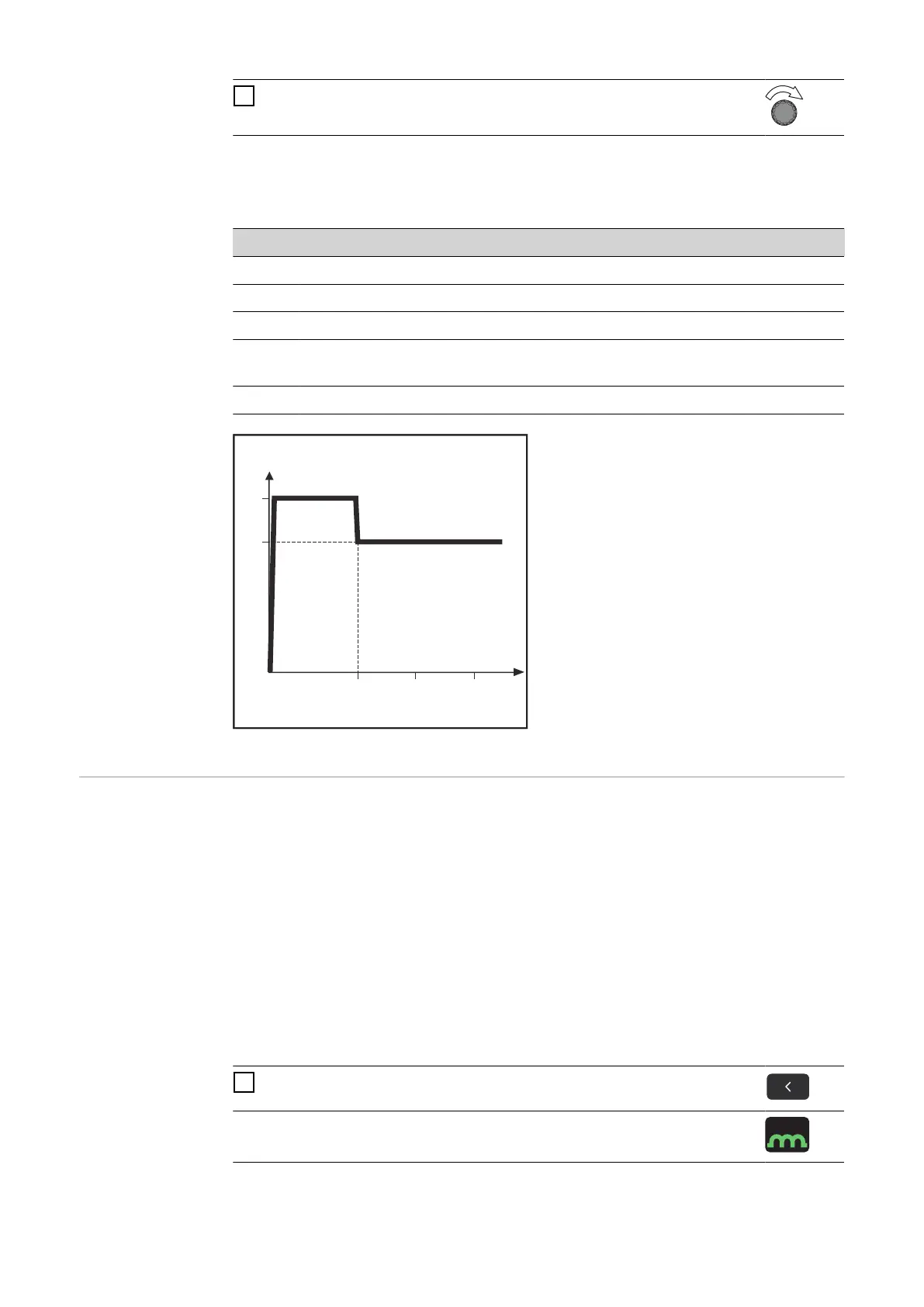

I (A)

t

90A

0,5 s 1 s 1,5 s

120A

Example of HotStart function

Features of SoftStart function:

-

Reduced pore formation with cer-

tain electrode types

Features of HotStart function:

-

Improved ignition properties, even

when using electrodes with poor

ignition properties

-

Better fusion of the base material

during the start-up phase, meaning

fewer cold-shut defects

-

Largely prevents slag inclusions

Arc-force dy-

namic

To obtain optimum welding results, it will sometimes be necessary to adjust the

arc-force dynamic.

Setting range: 0 - 100 (corresponds to 0 - 200 A current increase)

Operating principle:

At the moment of droplet transfer or in the event of a short circuit, the amper-

age is briefly increased in order to obtain a stable arc.

If the rod electrode is at risk of sinking into the weld pool, this measure prevents

the weld pool from solidifying, as well as preventing a prolonged short-circuit of

the arc. This largely prevents the rod electrode from sticking.

Setting the arc-force dynamic:

1

Press the setting value button until

-

the arc-force dynamic indicator lights up

28

Loading...

Loading...