NOTE!

If Fdc is set to AUT, the value from the welding program database will be used.

If Fdc values are set manually and these values are faster than the wire feed speed that

was set for the welding operation then the feeder creep speed is equal to the wire feed

speed set for the welding operation.

Fdi

Feeder inching

Unit m/min ipm

Setting range 1 - max. 39.37 - max.

Factory setting 10 393.7

NOTE!

To facilitate the exact positioning of the wire electrode, the following sequences

are possible when the welder presses and holds the Feeder inching button down:

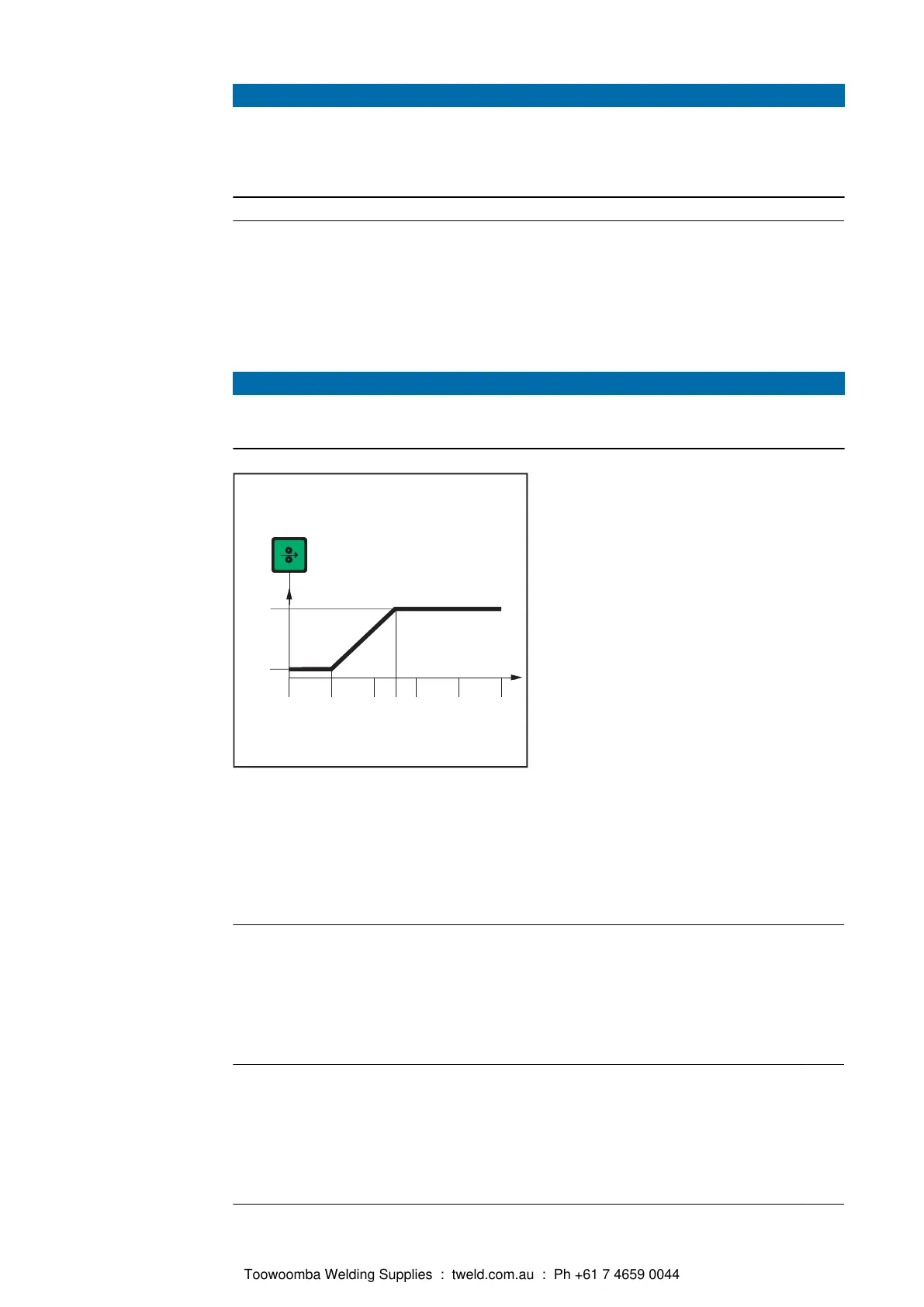

t (s)

123452,5

1

Fdi

(z.B. 22)

Passage over time of the wire feed speed when the

feeder inching button is pressed and held down

- Hold down the button for up to one

second ... Irrespective of the value

that has been set, the wire feed speed

remains at

1 m/min or 39.37 ipm for the first

second.

- Hold the button for up to 2.5

seconds ... After one second, the

wire feed speed increases at a uni-

form rate over the next 1.5 seconds.

- Hold the button for longer than 2.5

seconds ... After a total of 2.5

seconds, the wire is fed at a constant

rate equal to the wire feed speed set

for the Fdi welding parameter.

If the Feeder inching button is released and pressed again before one second has

elapsed, the sequence starts again from the beginning. This makes it possible to position

the wire continuously at the low wire feed speed of 1 m/min or 39.37 ipm when neces-

sary.

bbc

Burn-back time correction

Unit s

Setting range ± 0.20

Factory setting 0

dYn

dynamic - Arc force dynamic correction

Unit 1

Setting range ± 5

Factory setting -

142

Toowoomba Welding Supplies : tweld.com.au : Ph +61 7 4659 0044

Loading...

Loading...