3

1.0

SAFETY INFORMATION

READ BEFORE INSTALLING OR OPERATING

NOTE: THIS MACHINE IS AUTOMATICALLY CONTROLLED AND MAY START AT

ANY TIME.

All CNC machines contain hazards from rotating parts, belts and pulleys, high voltage electricity, noise, and

compressed air. When using CNC machines and their components, basic safety precautions, including all

appropriate LOTO procedures must always be followed to reduce the risk of personal injury and mechanical

damage.

It is the machine owner’s responsibility to make sure all personnel who are involved in installation and operation of this

machine are thoroughly acquainted with the procedures and safety instructions provided herein BEFORE they perform

any actual work.

Only Fryer factory-trained service personnel should troubleshoot and repair the equipment.

Do not modify or alter this equipment in any way without first consulting Fryer Machine. Any modification or alteration of

this equipment could lead to personal injury and/or mechanical damage and could void your warranty.

1. Keep machine and area around it clean and well lit. Never allow chips, coolant, or oil to remain on the floor. Do not

leave loose objects on or around machine.

2. Use appropriate eye and ear protection while operating the machine. ANSI-approved impact safety goggles and

OSHA-approved ear protection are recommended to reduce the risks of eye injury and hearing loss.

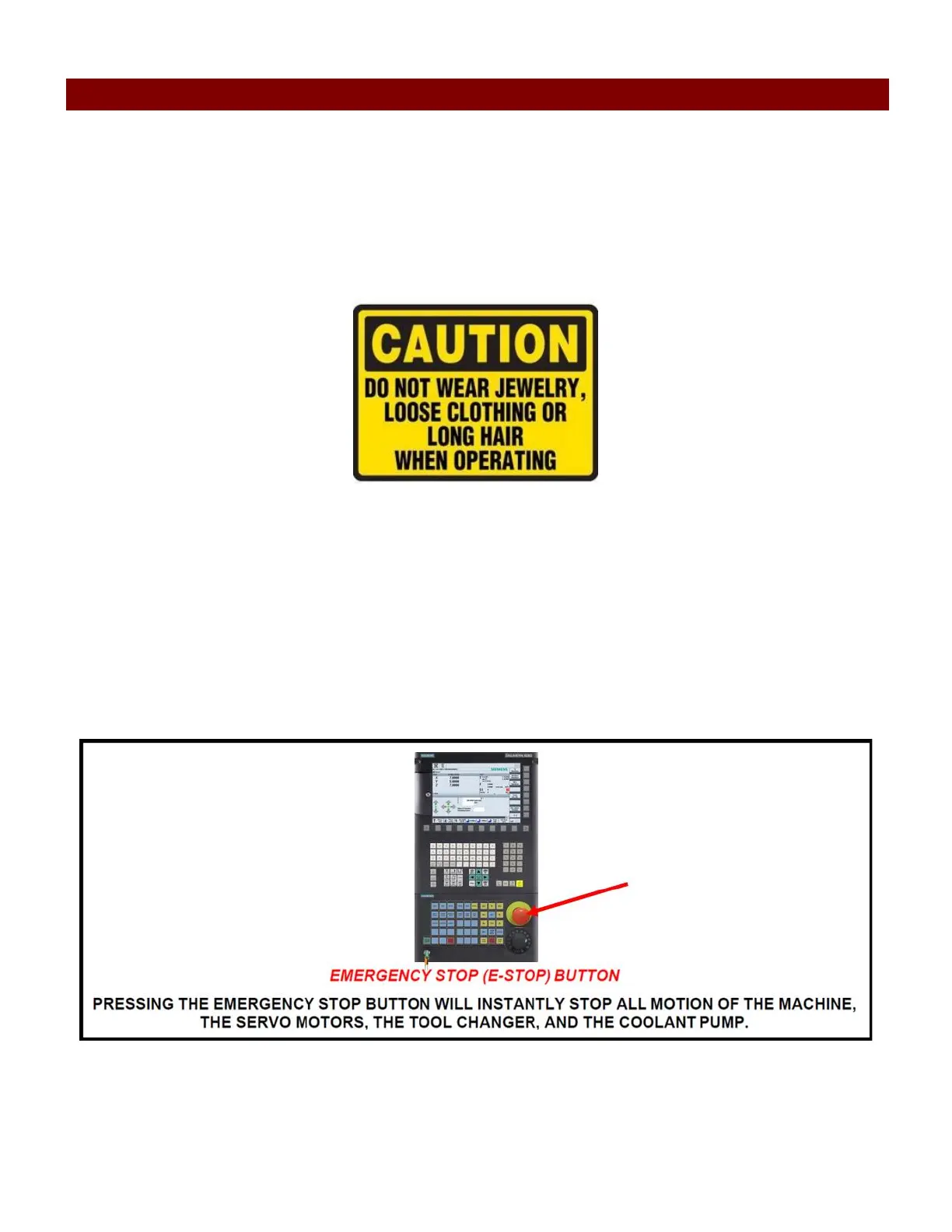

Loading...

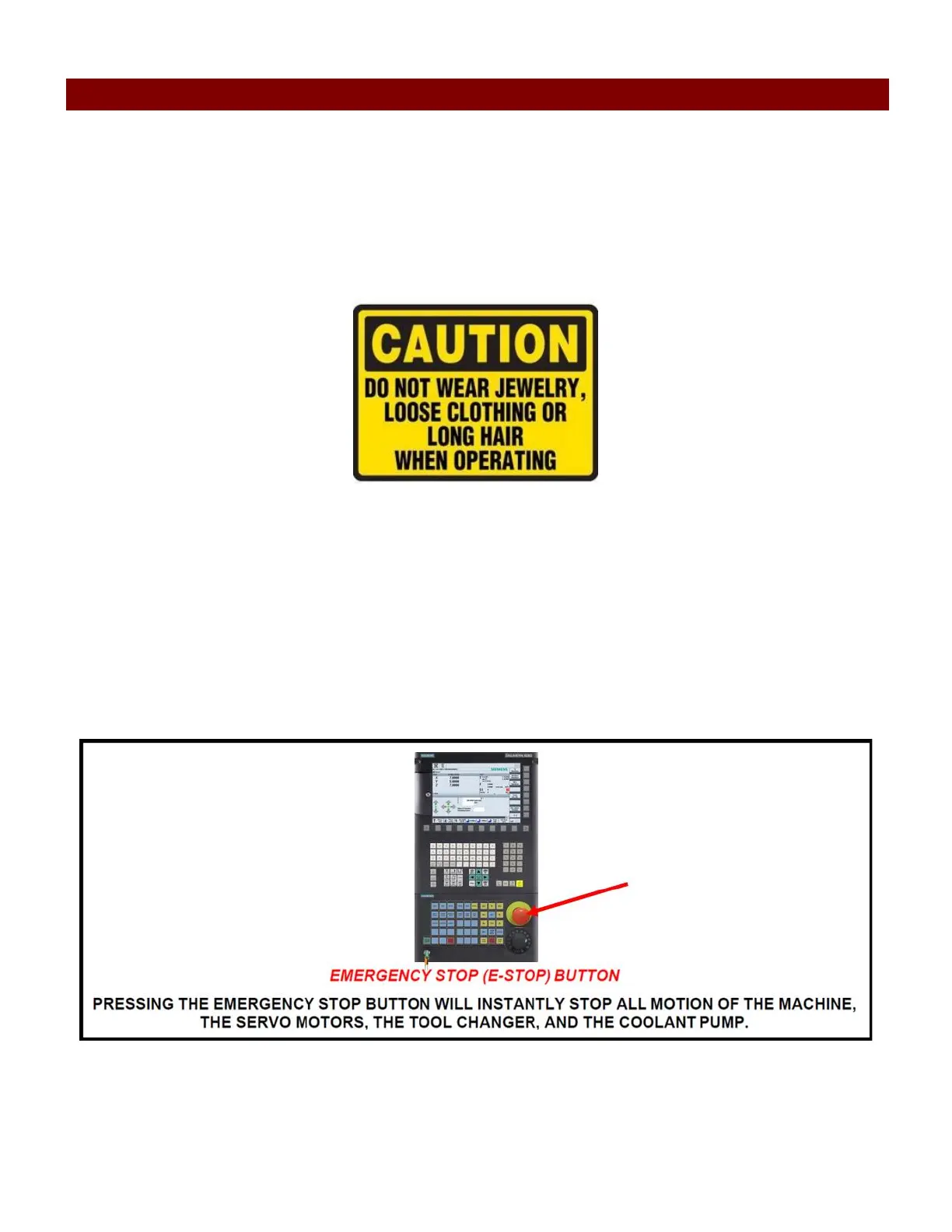

Loading...