Warning

Connector Connections

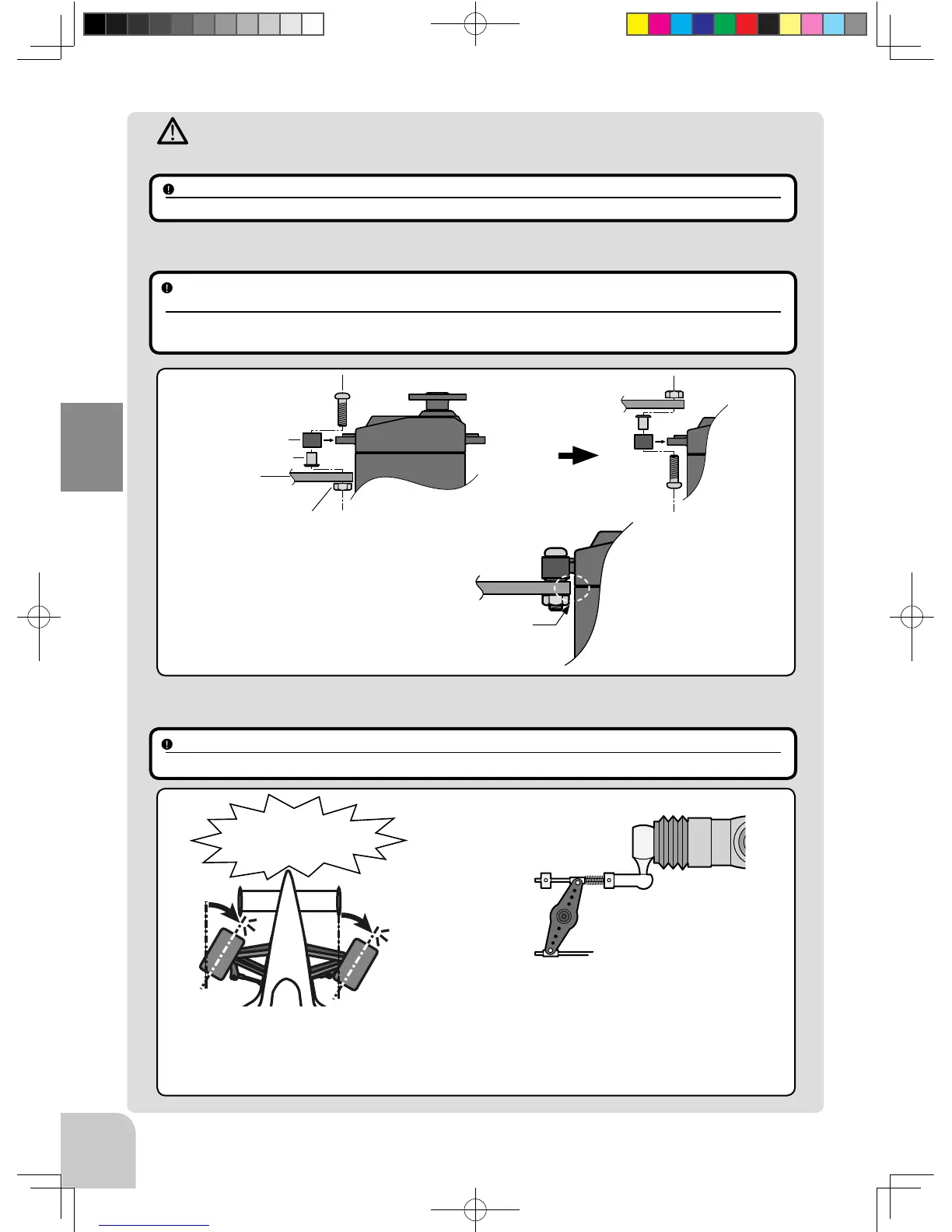

Servo Installation

Be sure the receiver, servo, battery and connectors are fully and firmly connected.

If vibration from the model causes a connector to work loose while the model is in operation, you may lose control .

When you install the servos, always use the rubber grommets provided in servo hardware bags. Mount the

servos so they do not directly come in contact with the mount.

If the servo case comes in direct contact with the mount, vibration will be directly transmitted to the servo.

If this condition continues for a long time, the servo may be damaged and control will be lost.

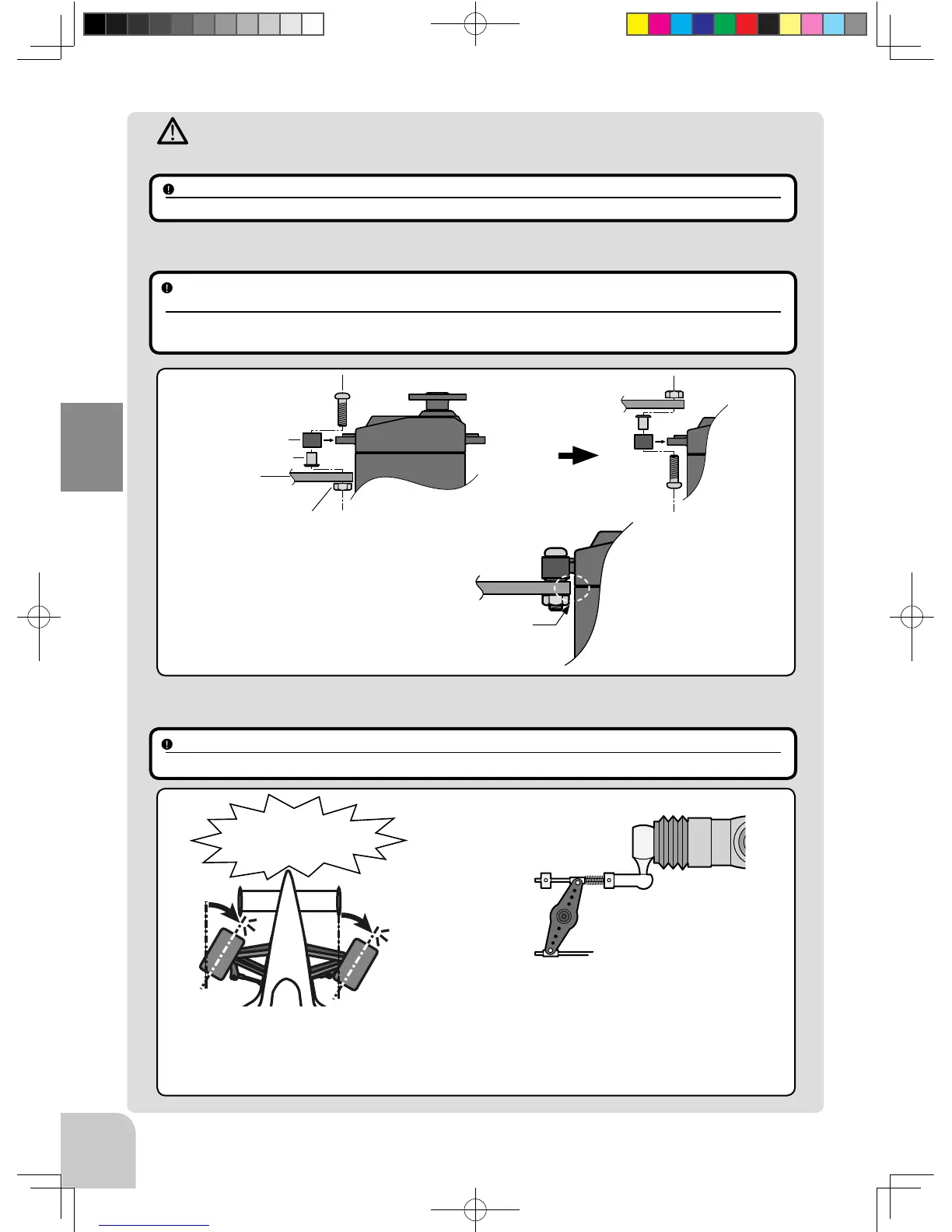

Servo Throw

Operate each servo over its full stroke and be sure the linkage does not bind or is loose.

The continuous application of unreasonable force to a servo may cause damage and excessive battery drain.

Screw

Mechanical plate

Nut (as required)

Eyelet

Damper

(or)

When installing the servo, always install the accessory

rubber grommet and grommet ush against the servo.

A vibration-damping effect is not obtained even

if the rubber grommet and grommet are not in-

stalled correctly.

Adjust the throttle servo so that unreasonable force is

not applied when the engine carburetor is fully open,

fully closed, and the brakes are applied fully.

If the brakes overheat while running, their ability to

function properly decreases. Before running, adjust the

suitable maximum servo travel so that unreasonable

force is not applied even when the servo travel is in-

creased while running.

Adjust the steering servo so that unreason-

able force is not applied to the servo by the

chassis at maximum servo travel.

Decide the EPA value at the

contact point.

Caution!

A whining noise indicates that the

steering servo is improperly set.

34

Loading...

Loading...