CHAPTER 2: INSTALLATION MAINTENANCE

MM300 MOTOR MANAGEMENT SYSTEM – QUICKSTART GUIDE 17

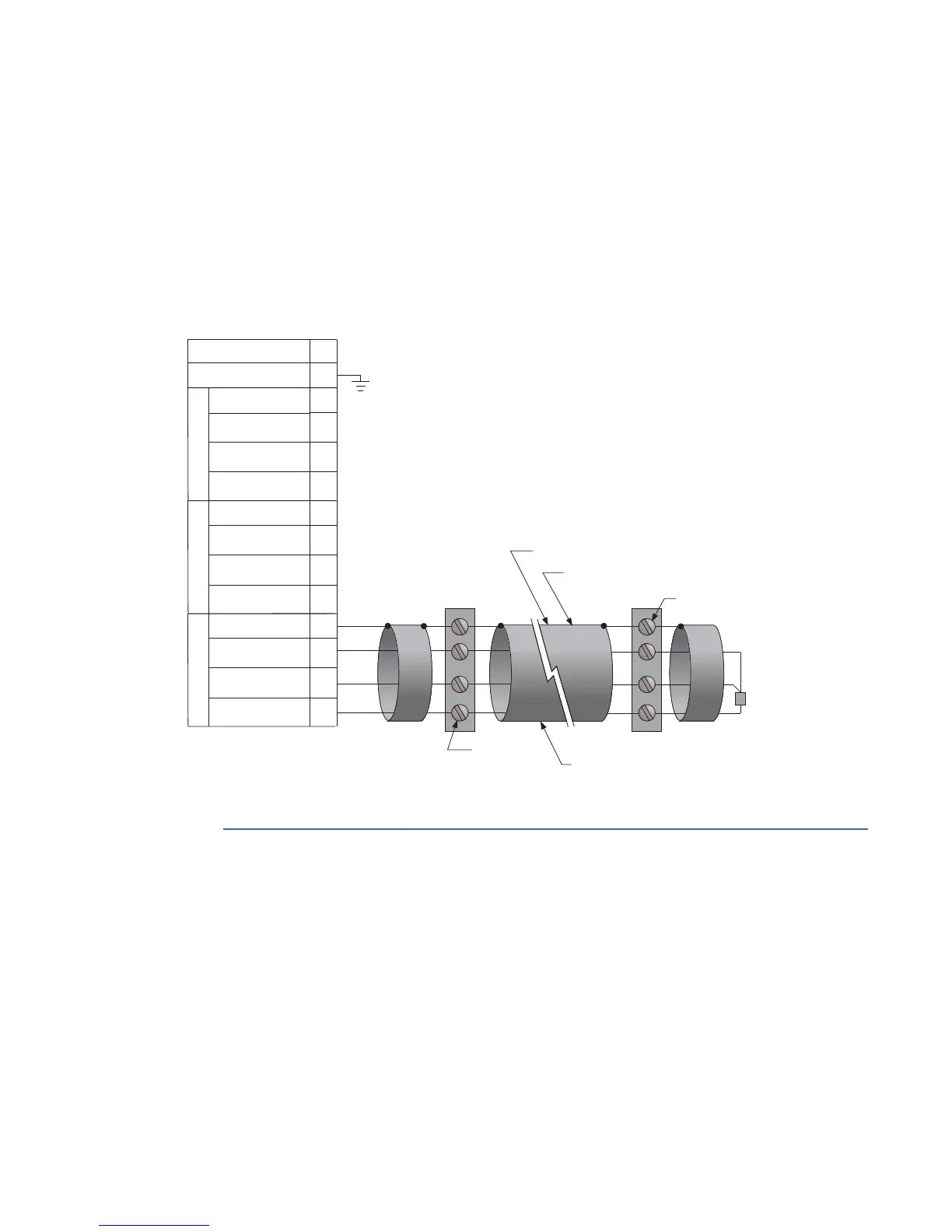

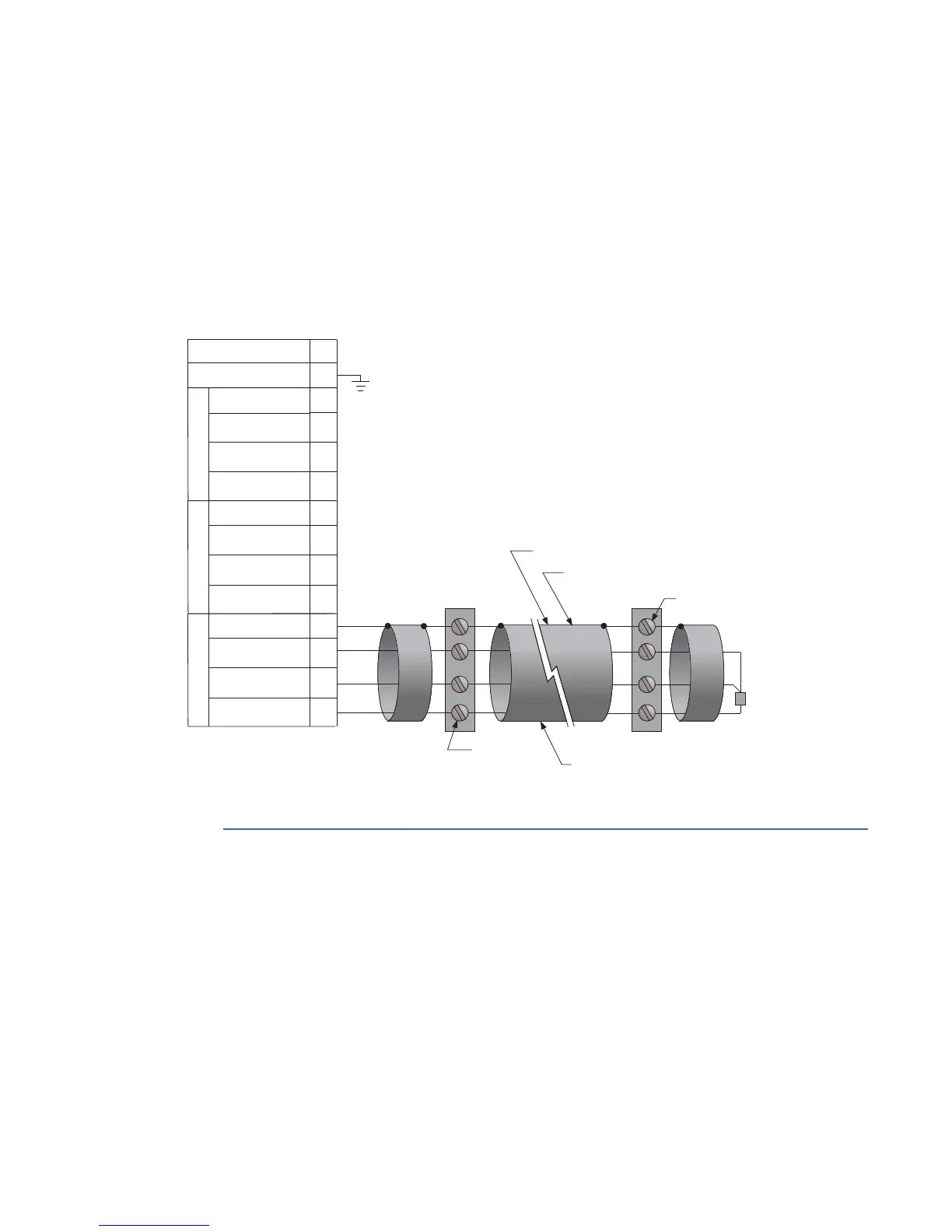

The MM300 monitors up to six RTD inputs for stator, bearing, ambient, or other

temperature monitoring types. The type of each RTD is 100 ohm platinum (DIN 43760).

RTDs must be three-wire type.

The RTD circuitry compensates for lead resistance, provided that each of the three leads is

the same length. Lead resistance should not exceed 25 ohms per lead. Shielded cable

should be used to prevent noise pickup in industrial environments. RTD cables should be

kept close to grounded metal casings and away from areas of high electromagnetic or

radio interference. RTD leads should not be run adjacent to or in the same conduit as high

current carrying wires.

Figure 2-21: RTD wiring

Maintenance

The MM300 requires minimal maintenance. As a microprocessor-based relay, its

characteristics do not change over time. The expected service life of an MM300 is 20 years

when the environment and electrical conditions are within stated specifications.

While the MM300 performs continual self-tests, it is recommended that maintenance be

scheduled with other system maintenance. This maintenance can involve in-service, out-

of-service, or unscheduled maintenance.

In-service maintenance

1. Visual verification of the analog values integrity, such as voltage and current (in

comparison to other devices on the corresponding system).

Motor

starter

Motor

Three-wire shielded cable

RTD

terminals in

motor starter

RTD terminals

at motor

Maximum total lead resistance:

25 ohms for Platinum RTDs

Route cable in separate conduit from

current carrying conductors

RTD in motor

stator or

bearing

853737A3.CDR

MM300 Motor Protection Syst em

Surge ground

~13

~4

~3

~2

~1

Compensation

Return

Hot

Shield

RTD1

~8

~7

~6

~5

Compensation

Return

Hot

Shield

RTD2

~12

~11

~10

~9

Compensation

Return

Hot

Shield

RTD3

N/C

~14

Loading...

Loading...