8. Maintenance and Inspection

8-2

(2) Periodic inspections

Table 8-2

Inspection item Inspection details and work

VAT2000 appearance Check the state of dirt and dust on the vent or heatsink, and clean if necessary.

VAT2000 interior Check the state of dirt and dust on the PCB and inside the equipment, and

clean if necessary.

Terminal block Tighten the terminal block screws if loose.

Cooling fan Replace the fan every three years.

Electrolytic capacitor Confirm that there is no liquid leaking or sheath discoloration.

Insulation resistance

inspection

Do not perform a megger test on the VAT2000. When doing a megger test on

the external circuit, disconnect all wires connected to the VAT2000.

Encoder Confirm that there is no looseness or play in the bearings or couplings.

The bearings are durable parts. This is approx. 10,000 hours at 6000rpm, and

approx. 30,000 hours at 3000rpm.They must be replaced periodically.

(3) Inspection of spare VAT2000

The inspection shown in Table 8-2 must also be performed for spare VAT2000 that are left

connected but are not used in normal operation. The operation of the VAT2000 must be checked

every six months by turning the power on.

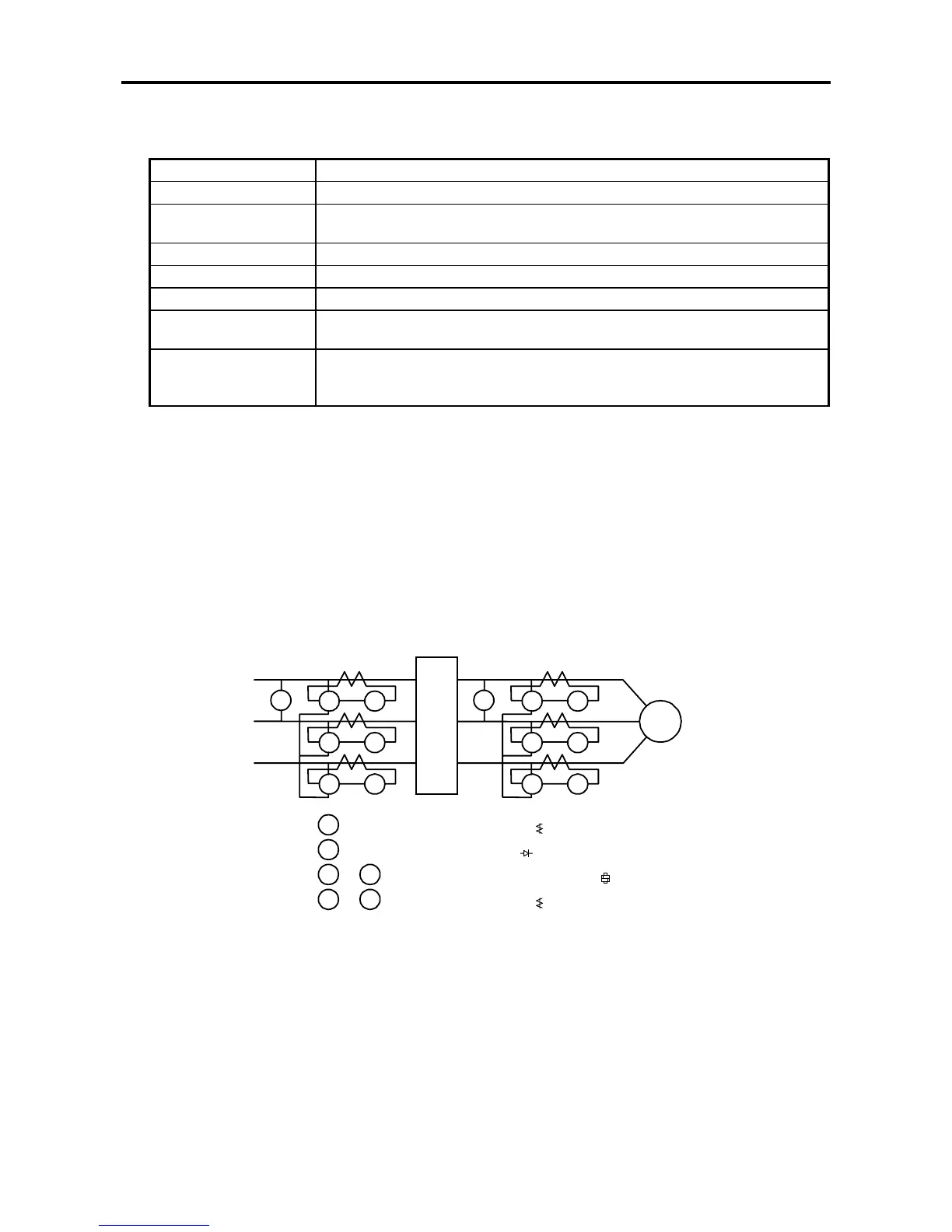

8-2 Measuring devices

As the voltage and current on the input and output sides include high harmonics, the measured value will

differ according to the measuring device. When measuring with a device for commercial frequencies,

measure with the following circuits and noted measuring devices.

W

1

W

4

W

2

W

5

W

3

V

1

V

1

V

2

W

1

W

6

A

1

A

6

to

to

V

2

W

6

A

1

A

4

A

2

A

5

A

3

A

6

M

Moving iron type Voltmeter

(

(

(

(

)

)

)

)

Power Supply

Moving iron type Ammeter

Rectifier type Voltmeter

Electrodynamometer type power meter

Inverter

Fig. 8-1 Measurement circuit example

Loading...

Loading...