5. Control Input / Output

5-16

5-9-3 Torque bias 1 setting

(1) Torque bias 1 setting selection

A torque bias setting is possible from either analog signals, serial communications or from the

operation panel. All these are selectable by the user.

Setting

input point

Setting data Explanation

Analog Analog torque bias 1

setting

This torque bias setting is possible from an analog input.

Serial

Serial torque bias 1

setting

This torque setting is allowed from a host computer with

serial transmission.

A serial interface option type U2KV23SL0 is required.

Panel Panel torque bias 1

setting

This torque bias setting is allowed by parameter (B13-0).

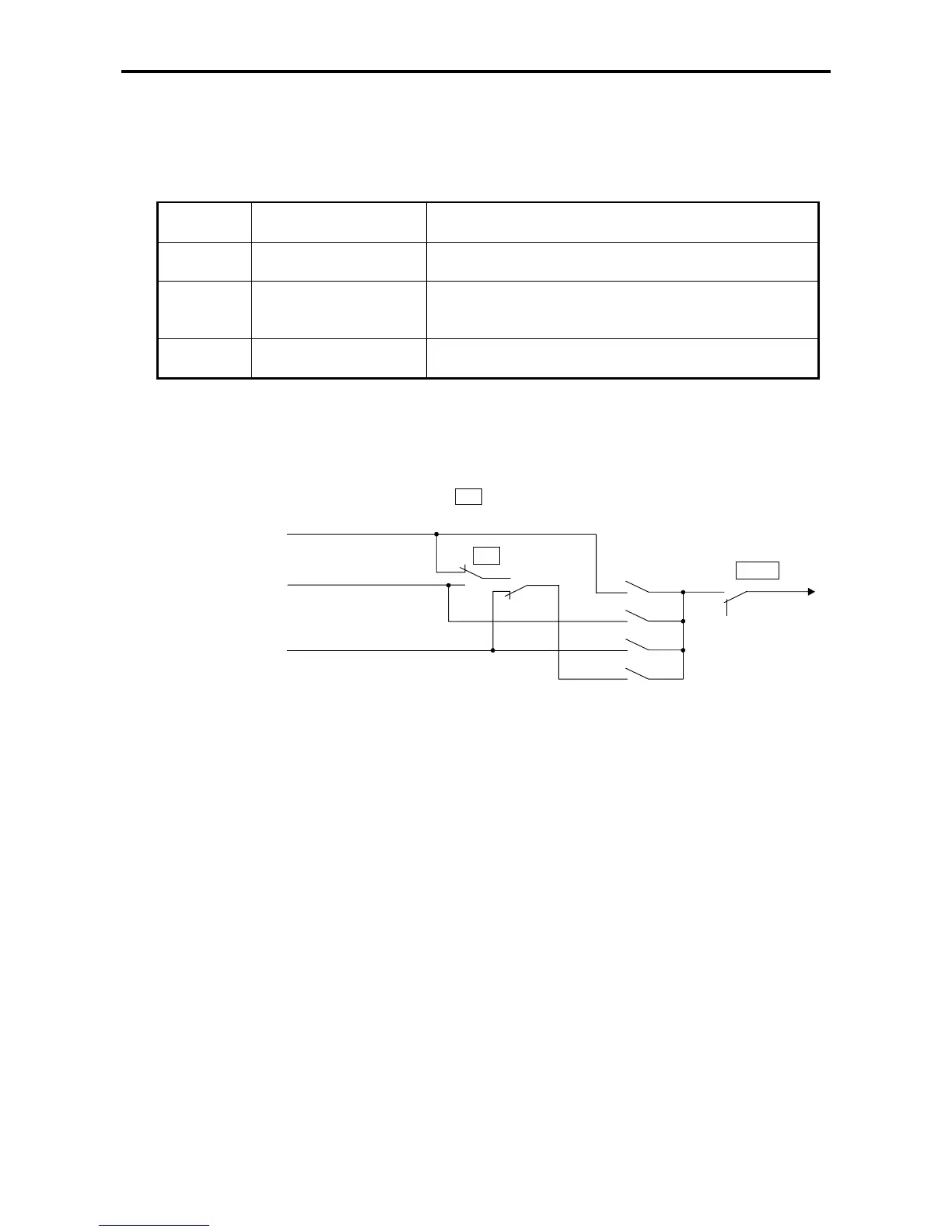

(2) Torque bias 1 setting selection sequence

The relation of the torque bias 1 setting and changeover sequence is shown below.

Analog Torque

bias 1 setting (C07-9)

Serial communication Torque

bias 1 setting

Operation panel

Torque bias 1 setting

(B13-2)

Torque bias 1

setting

LCL

on

off

off

off

on

on

0

C02-4

=1

=2

=3

=4

Functions that can be controlled ON / OFF

from terminal board

XXX

CFS

TRQB1

Fig. 5-11 Torque bias 1 setting selection

5-9-4 Torque limiter function

(1) Torque limit setting selection

The torque limit can be set independently for both speed control (ASR mode) or torque control (ACR

mode) independently for drive or regeneration status. If the VAT2000 is stopped by the emergency

stop signal (EMS), then the regeneration limit is fixed by parameter A10-5.

The parameters used in the torque limiter function are shown below..

A10-3 : ASR drive torque limit setting

A10-4 : ASR regenerative torque limit setting

A10-5 : Emergency stop regenerative torque limit setting

A11-2 : ACR drive torque limit setting

A11-3 : ACR regenerative torque limit setting

The value of above limits can be reduced by external settings. The final limit value results multiplying

the above selected limit with the reduction ratio.

Loading...

Loading...