6. Control Functions and Parameter Settings

6-6

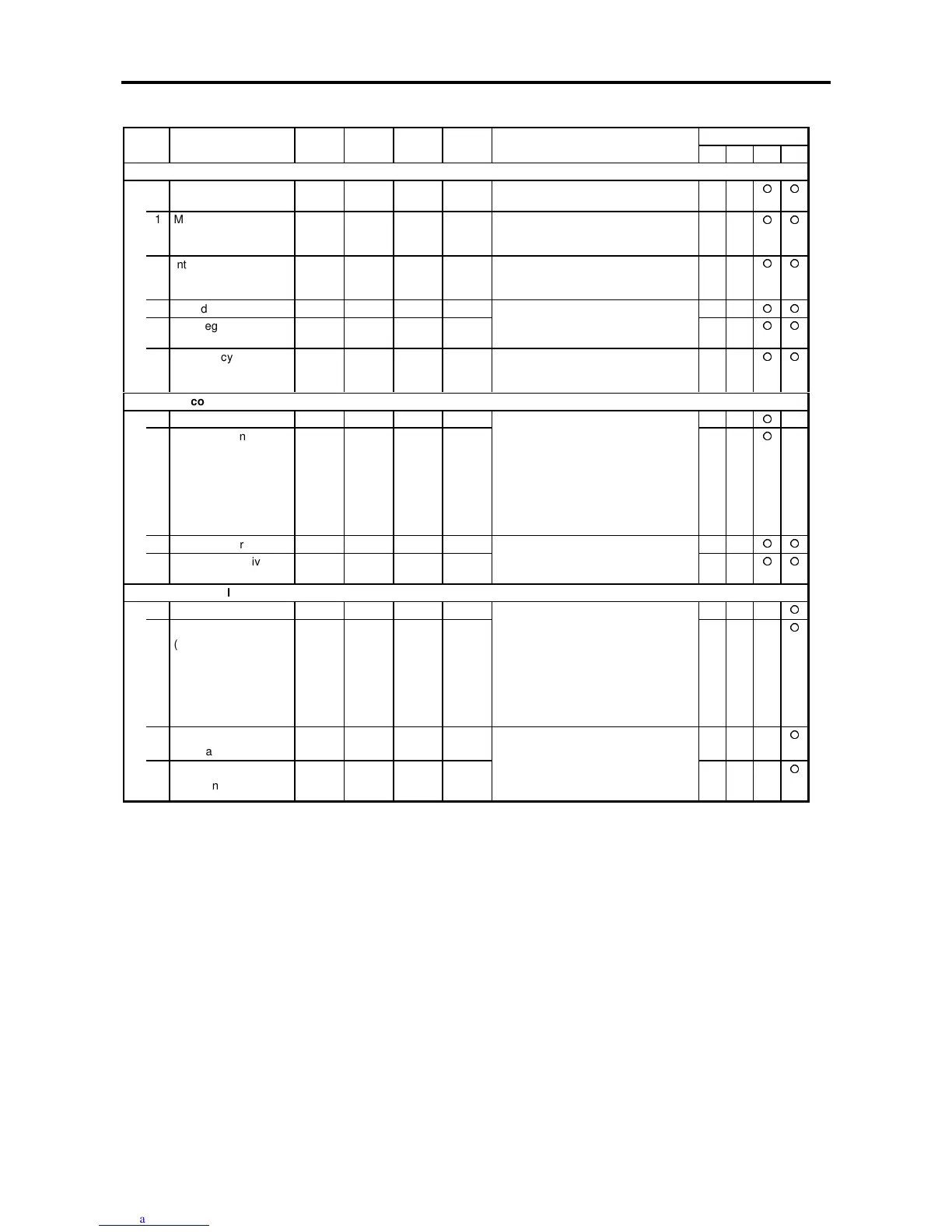

Block-A parameters list

ApplicationNo. Parameter Unit Default Min. Max. Function

ST V/f VEC PM

A10 – ASR control constant 1

0 ASR response rad/s 20.0 1.0 200.0 This is the required ASR response in

radian/sec.

1 Machine time

constant1

ms 1000. 1. 20000. This is the time to accelerate the

motor + load to the base speed at the

motor rated torque.

2 Integral time constant

compensation

coefficient

% 100. 20. 500. This is a compensation coefficient for

the Integral time constant in the

speed regulator.

3 ASR drive torque limit % 100.0 0.1 300.0

4 ASR regenerative

torque limit

% 100.0 0.1 300.0

These are the drive and regenerative

torque limit values for ASR operation.

(Speed Control)

5 Emergency stop

regenerative torque

limit

% 100.0 0.1 300.0 This is the regenerative torque limit

used during the emergency stop

(EMS)

A11 – ACR control constant

0 ACR response rad/s 1000. 100. 6000.

1 ACR time constant ms 20.0 0.1 300.0

The ACR gain and time constant are

set.

This will affect the current response. If

the gain is too low or too high, the

current will become unstable, and the

over current protection will function.

Normally adjust the response

between 500 and 1000, and the time

constant between 5 and 20ms.

2 ACR drive torque limit % 100.0 0.1 300.0

3 ACR regenerative

torque limit

% 100.0 0.1 300.0

Drive and regenerative torque limit

values for ACR operation.

(Torque Control)

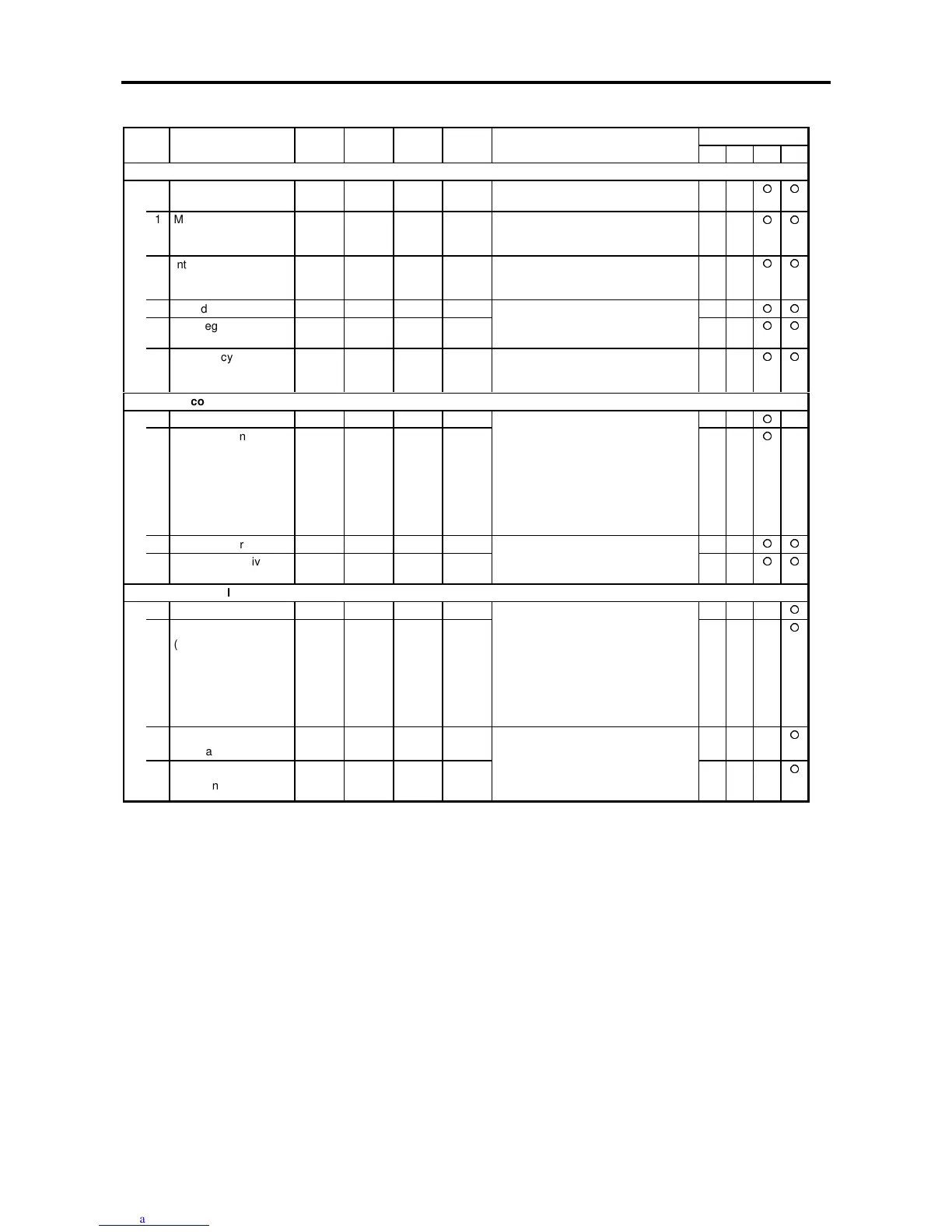

A20 – ACR control constant (Permanent Magnet Motors)

0 ACR response (PM) rad/s 1500 100. 6000.

1 ACR time constant

(PM)

ms 10.0 0.1 300.0

These are the gain and time constant

for the current regulator (ACR)

This will affect the current response. If

the gain is too low or too high, the

current will become unstable, and the

VAT2000 may trip by overcurrent .

In general, adjust the response

between 500 and 1000, and the time

constant between 5 and 20ms.

2 d axis current

command ramp time

ms/I1 10.0 0.1 100.0

3 q axis current

command ramp time

ms/I1 10.0 0.1 100.0

This is the ramp setting to prevent

instability caused by overshooting, etc

when current command changes

suddenly.

Set usually a value of 5-10 ms

Loading...

Loading...