9 Maintenance

This chapter

contains information about valve maintenance, inspection and repairs. It

also describes the personnel qualications required for the individual actions.

It is addressed to all persons who carry out actions related to the valve.

INFO During all repair work, observe the chapter

2 Safety

of this Operating In-

structions.

9.1 Carrying out inspections

Between the maintenance periods, the valves must be checked for leakage and proper

function.

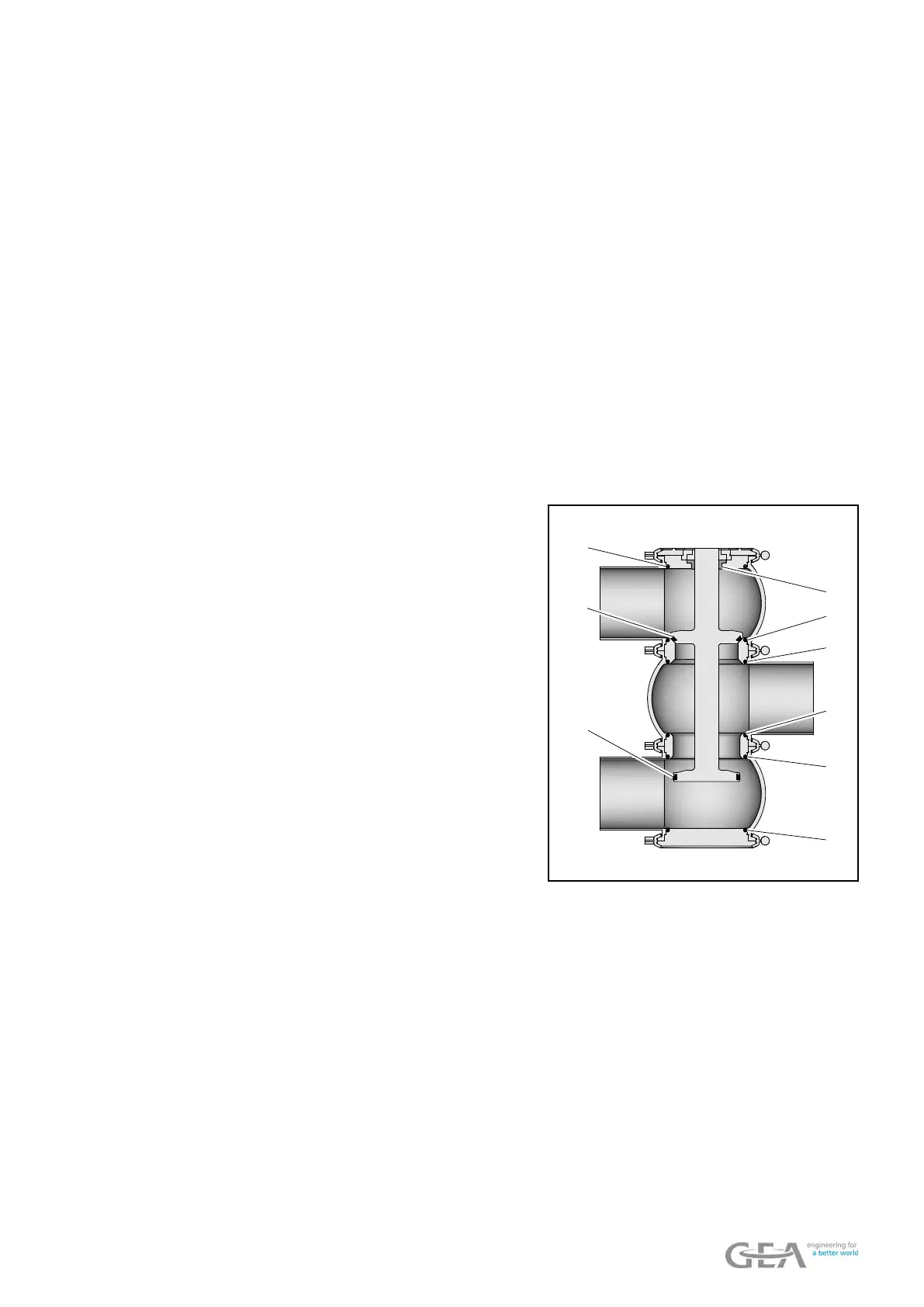

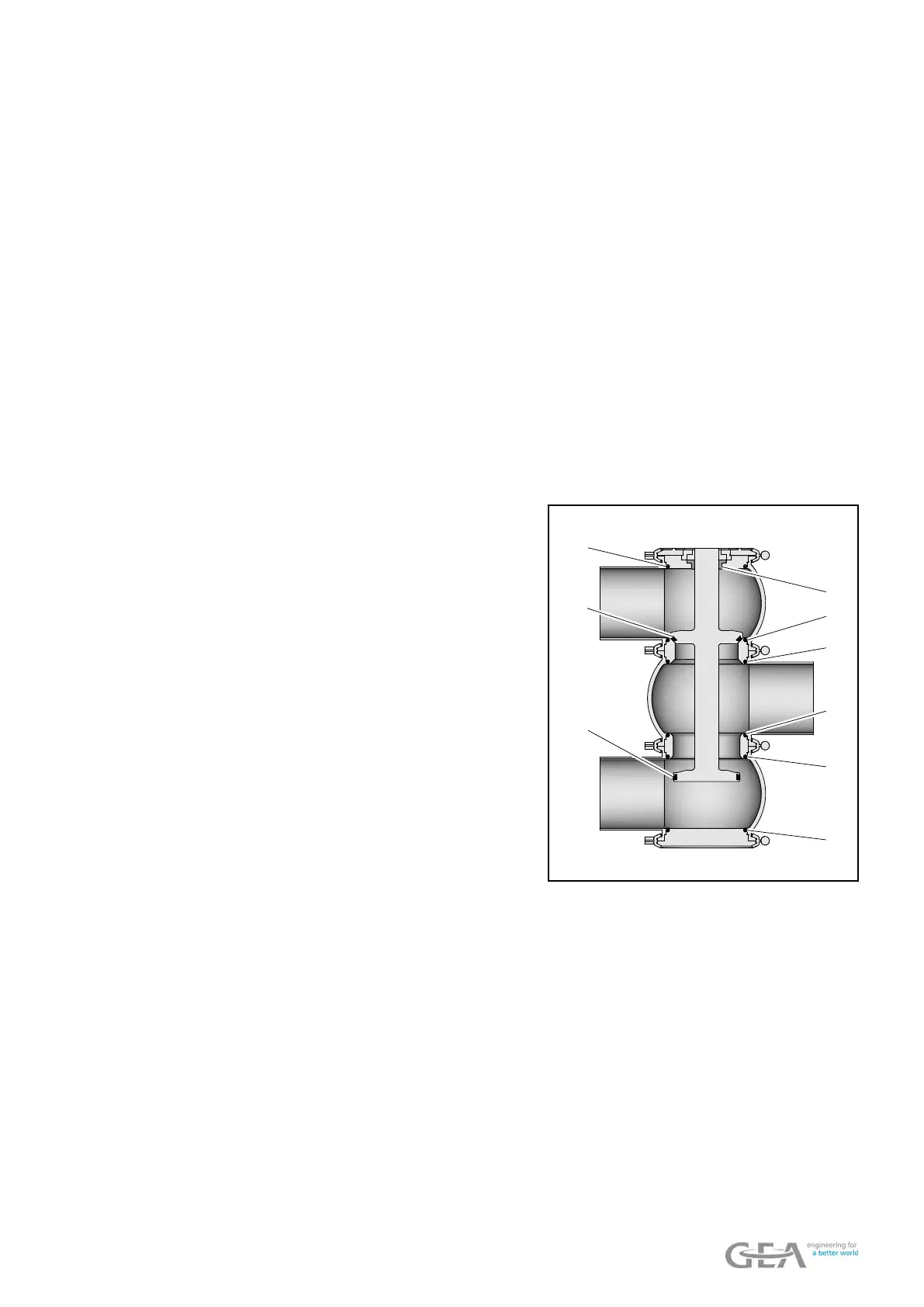

9.1.1 Checking seals that come into contact with the product

Prerequisites

●

Access to seals that come into contact with the product

1. Regularly

check seals that come into

contact with the product:

1.1 Check the seal ring between

upper housing and lantern.

1.2 Check the V-ring in the valve

disks.

1.3 Check the O-rings between the

valve housings.

Þ

Seals that come into contact with the product have been tested.

9.1.2 Checking the pneumatic connection

Prerequisites

●

Access to the pneumatic connection

1. Check the operating pressur

e at the pressure reducing and lter station.

2. Regularly clean the air lter in the lter station.

3. Check that the air connections are tight.

4. Check the lines for kinks and leaks.

5. Check the solenoid valves for proper function.

Þ

The pneumatic connection has been checked.

9.1 Carrying out inspections - 47 / 104

Loading...

Loading...