PRINTED IN U.S.A. 59 913225/CP0807

B2 - RADIATOR CORE

CLEAN

IMPORTANT: In a dirty atmosphere, clean the

radiator every day. Do not use a water jet or high-

pressure steam, because this could damage the

radiator fins.

- Open the engine cover.

- In order to prevent the radiator becoming clogged,

clean the radiator with a compressed air jet directed

from inside to outside. This is the only way to clean

the core of debris.

- If necessary, clean the screen on the engine cover.

B3 - AIR CONDITIONING CONDENSER

CORE (OPTION CT5-16 TURBO)

CLEAN

IMPORTANT: In a dirty atmosphere, clean the

condenser core every day. Do not use a water jet

or high-pressure steam, because this could dam-

age the fins.

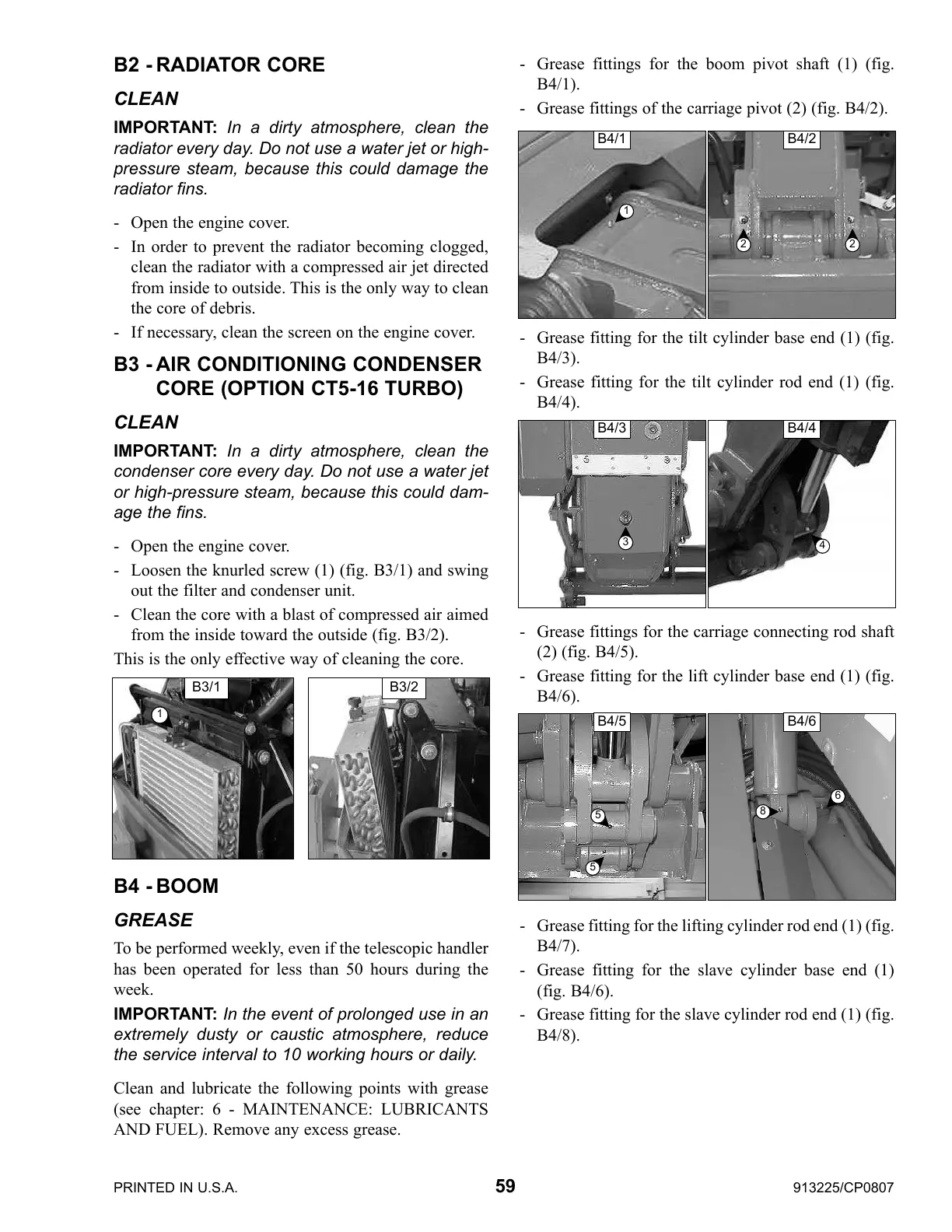

- Open the engine cover.

- Loosen the knurled screw (1) (fig. B3/1) and swing

out the filter and condenser unit.

- Clean the core with a blast of compressed air aimed

from the inside toward the outside (fig. B3/2).

This is the only effective way of cleaning the core.

B3/1 B3/2

1

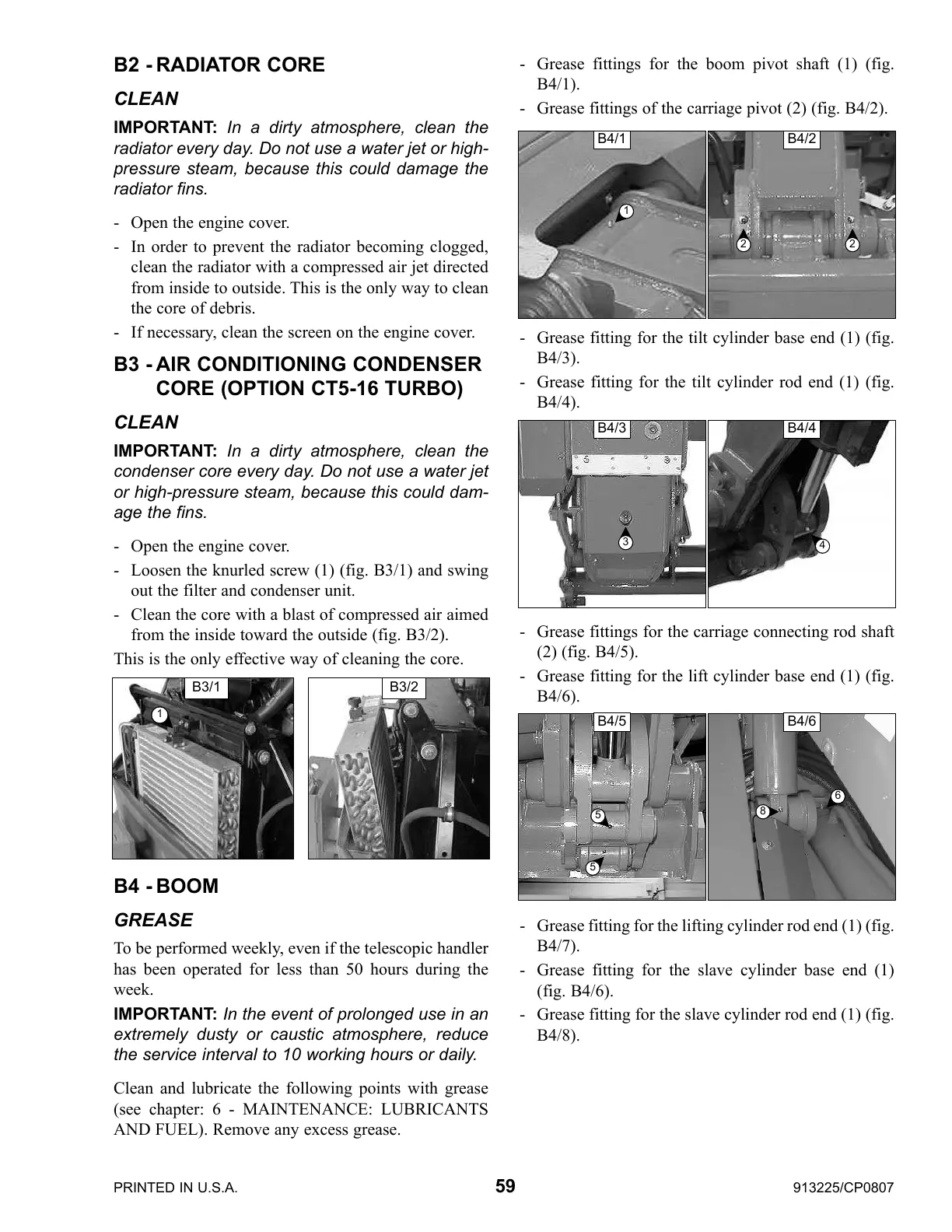

B4 - BOOM

GREASE

To be performed weekly, even if the telescopic handler

has been operated for less than 50 hours during the

week.

IMPORTANT: In the event of prolonged use in an

extremely dusty or caustic atmosphere, reduce

the service interval to 10 working hours or daily.

Clean and lubricate the following points with grease

(see chapter: 6 - MAINTENANCE: LUBRICANTS

AND FUEL). Remove any excess grease.

- Grease fittings for the boom pivot shaft (1) (fig.

B4/1).

- Grease fittings of the carriage pivot (2) (fig. B4/2).

- Grease fitting for the tilt cylinder base end (1) (fig.

B4/3).

- Grease fitting for the tilt cylinder rod end (1) (fig.

B4/4).

- Grease fittings for the carriage connecting rod shaft

(2) (fig. B4/5).

- Grease fitting for the lift cylinder base end (1) (fig.

B4/6).

- Grease fitting for the lifting cylinder rod end (1) (fig.

B4/7).

- Grease fitting for the slave cylinder base end (1)

(fig. B4/6).

- Grease fitting for the slave cylinder rod end (1) (fig.

B4/8).

B4/1 B4/2

2 2

1

B4/3 B4/4

3

4

B4/6B4/5

5

5

8

6

Courtesy of CraneMarket.com

Loading...

Loading...