PRINTED IN U.S.A. 63 913225/CP0807

b. Pivot the compressor assembly to obtain the

belt tension required.

c. Retighten screws.

COMPRESSOR TO ALTERNATOR BELT

- Check the belt tension between the compressor pul-

ley and of the alternator pulley.

- Under normal pressure exerted with the thumb of 10

lbf. (45N), the movement should be approximately

3/8” (10 mm).

- Adjustment if necessary:

a. Loosen mounting and adjuster screws two to

three turns.

b. Pivot the alternator assembly to obtain the belt

tension required.

c. Retighten screws.

- Replace the protective guard (2) (fig. C2/1).

NOTE: If the compressor belt is changed, check

the tension again after 20 hours of operation.

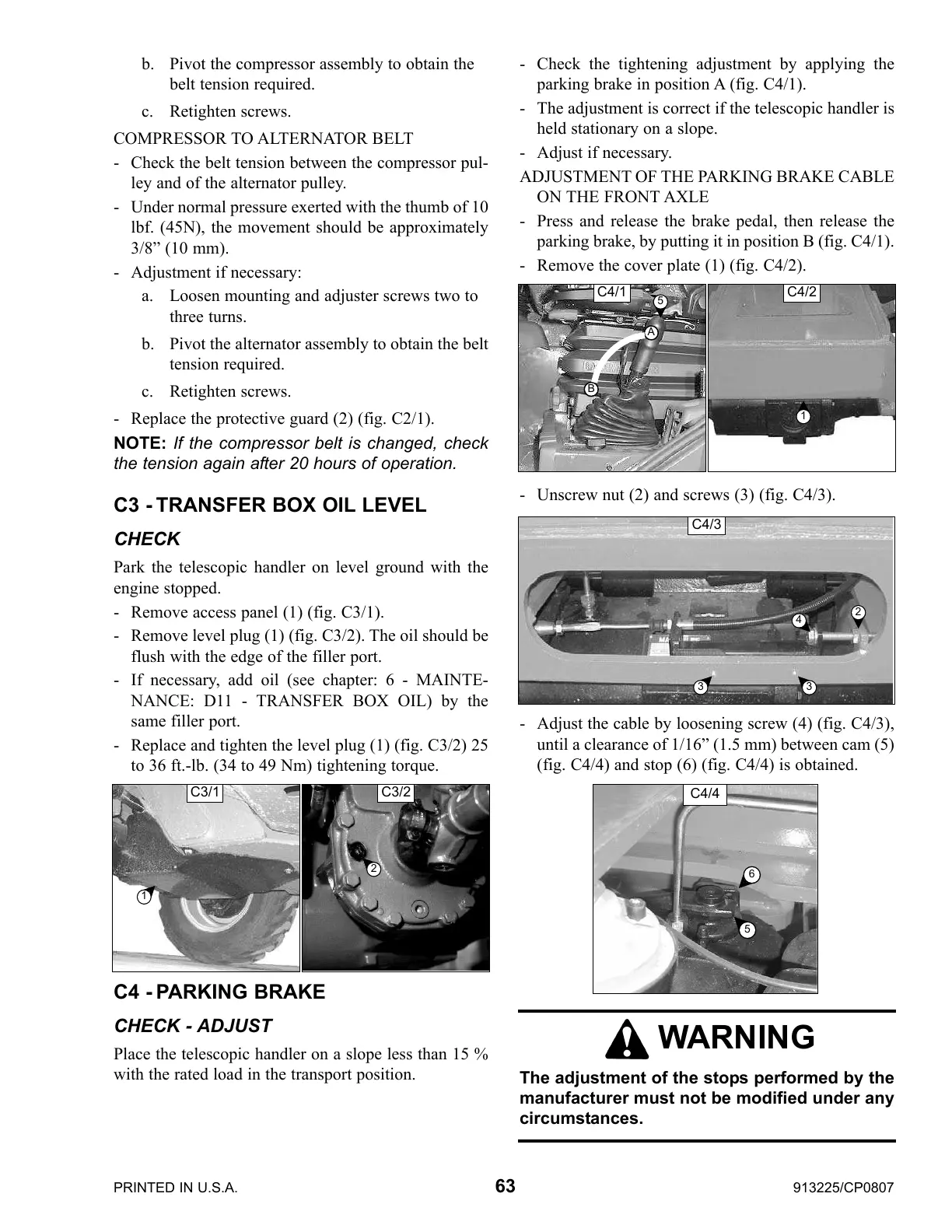

C3 - TRANSFER BOX OIL LEVEL

CHECK

Park the telescopic handler on level ground with the

engine stopped.

- Remove access panel (1) (fig. C3/1).

- Remove level plug (1) (fig. C3/2). The oil should be

flush with the edge of the filler port.

- If necessary, add oil (see chapter: 6 - MAINTE-

NANCE: D11 - TRANSFER BOX OIL) by the

same filler port.

- Replace and tighten the level plug (1) (fig. C3/2) 25

to 36 ft.-lb. (34 to 49 Nm) tightening torque.

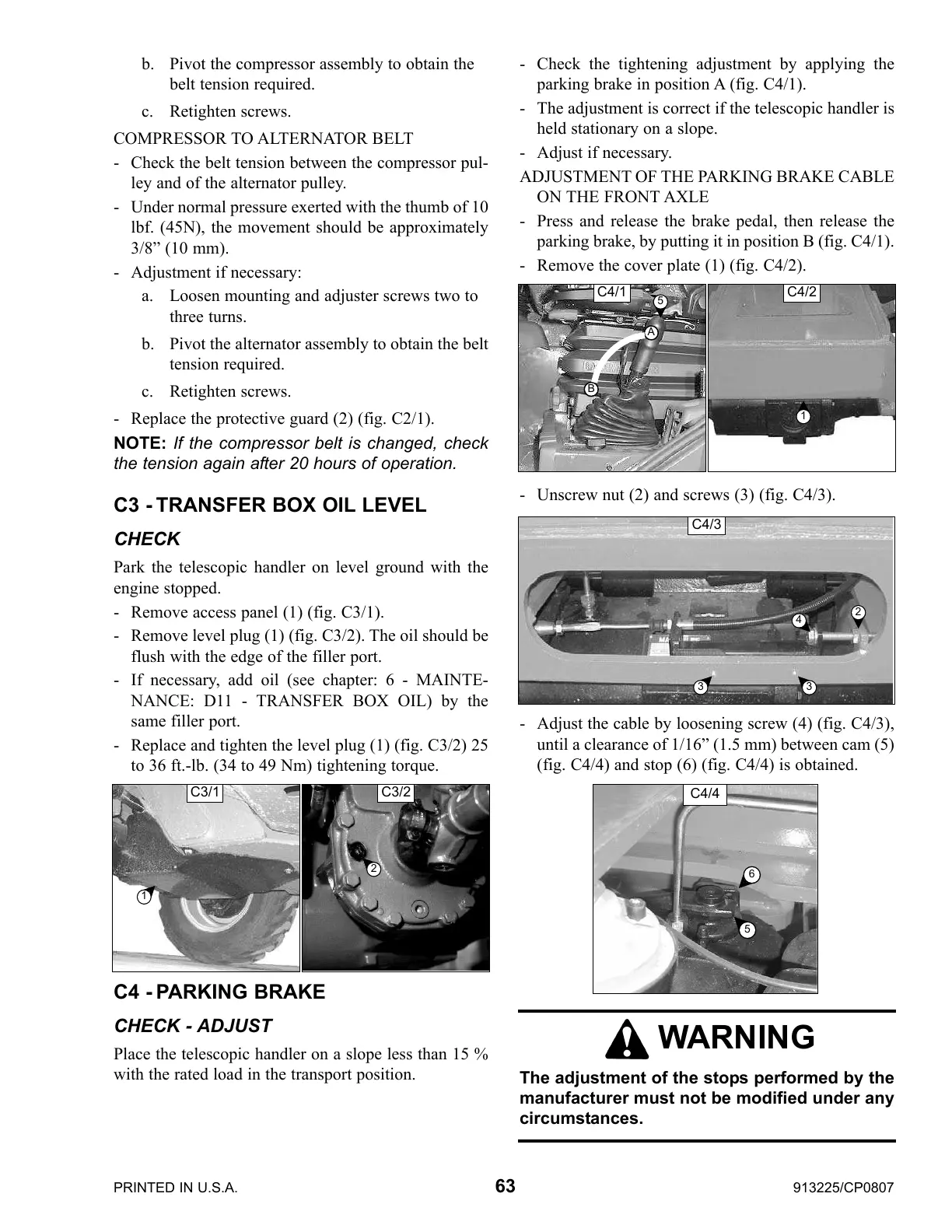

C4 - PARKING BRAKE

CHECK - ADJUST

Place the telescopic handler on a slope less than 15 %

with the rated load in the transport position.

- Check the tightening adjustment by applying the

parking brake in position A (fig. C4/1).

- The adjustment is correct if the telescopic handler is

held stationary on a slope.

- Adjust if necessary.

ADJUSTMENT OF THE PARKING BRAKE CABLE

ON THE FRONT AXLE

- Press and release the brake pedal, then release the

parking brake, by putting it in position B (fig. C4/1).

- Remove the cover plate (1) (fig. C4/2).

- Unscrew nut (2) and screws (3) (fig. C4/3).

- Adjust the cable by loosening screw (4) (fig. C4/3),

until a clearance of 1/16” (1.5 mm) between cam (5)

(fig. C4/4) and stop (6) (fig. C4/4) is obtained.

WARNING

The adjustment of the stops performed by the

manufacturer must not be modified under any

circumstances.

C4/3

C4/4

2

3

3

4

5

6

C3/2

2

C3/1

1

C4/1

5

A

B

C4/2

1

Courtesy of CraneMarket.com

Loading...

Loading...