32

Clutch

Installation:

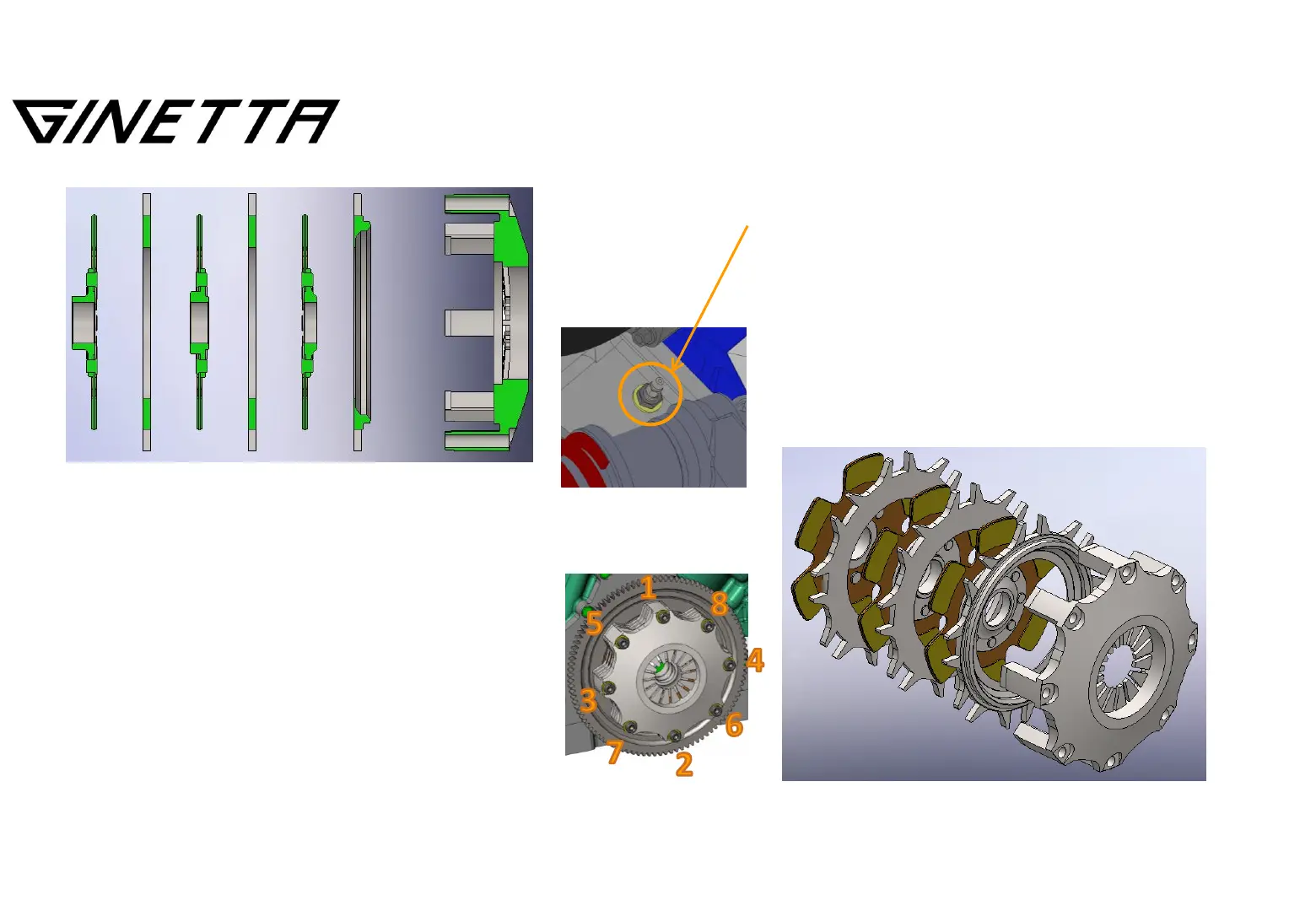

• Ensure all friction plates are aligned upon assembly

• Hub splines should be coated with Sachs grease and

aligned until input shaft moves smoothly through all

plates

• Excess grease should be removed as it is critical

that grease does not contact the friction faces

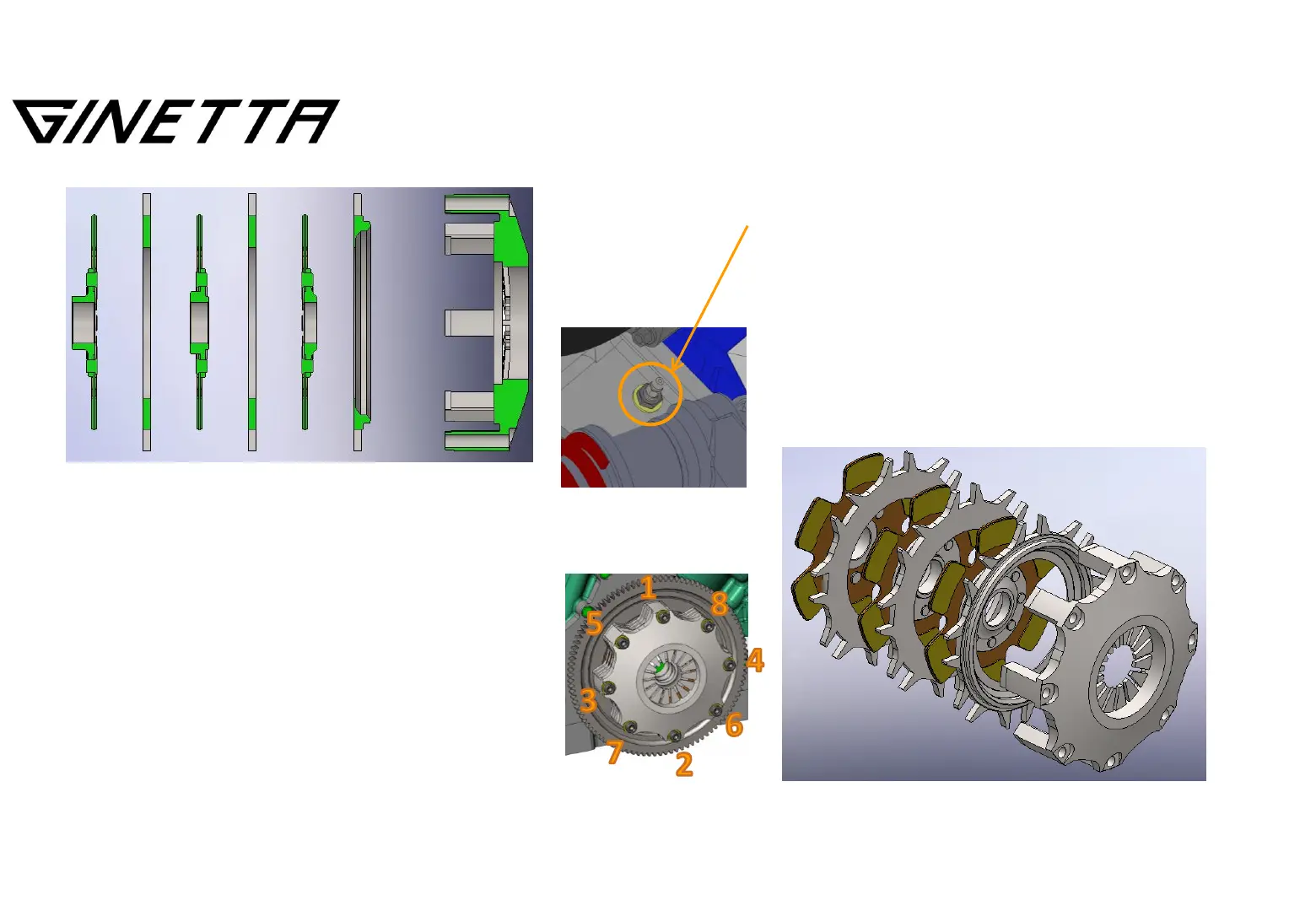

• Assembly should be fastened with Ginetta supplied cap

screws and plain washers

• Tightening torque 25 Nm (6mm hex socket)

• Use tightening sequence shown (1-8)

Maintenance:

• Clutch is blead via bleed nipple on shearplate

• Every two events or 1200km the clutch assembly should

be inspected and measured

• Upon inspection ensure:

• Each pressure plate is flat and parallel

• Each pressure plate slides freely in the clutch basket

• Max allowable stack wear 1.5mm from new

• No dramatically uneven wear on friction plates

• No excessive wear to clutch fingers

Loading...

Loading...