10

I

NSTALLATION

P

OSITIONS

This furnace may be installed in an upright position or horizontal on either the left or right side panel. Do not install this furnace

on its back. For upright upflow furnaces, return air ductwork may be attached to the side panel(s) and/or basepan. For horizontal

upflow furnaces, return air ductwork must be attached to the basepan. For both upright or horizontal counterflow furnaces, return

ductwork must be attached to the basepan (top end of the blower compartment). NOTE: Ductwork must never be attached to the

back of the furnace. Contact your distributor for proper airflow requirements and number of required ductwork connections. Refer

to “Recommended Installation Positions” figure for appropriate installation positions, ductwork connections, and resulting airflow

arrangements.

H

ORIZONTAL

A

PPLICATIONS

& C

ONSIDERATIONS

When installing a furnace horizontally, additional con-

sideration must be given to the following:

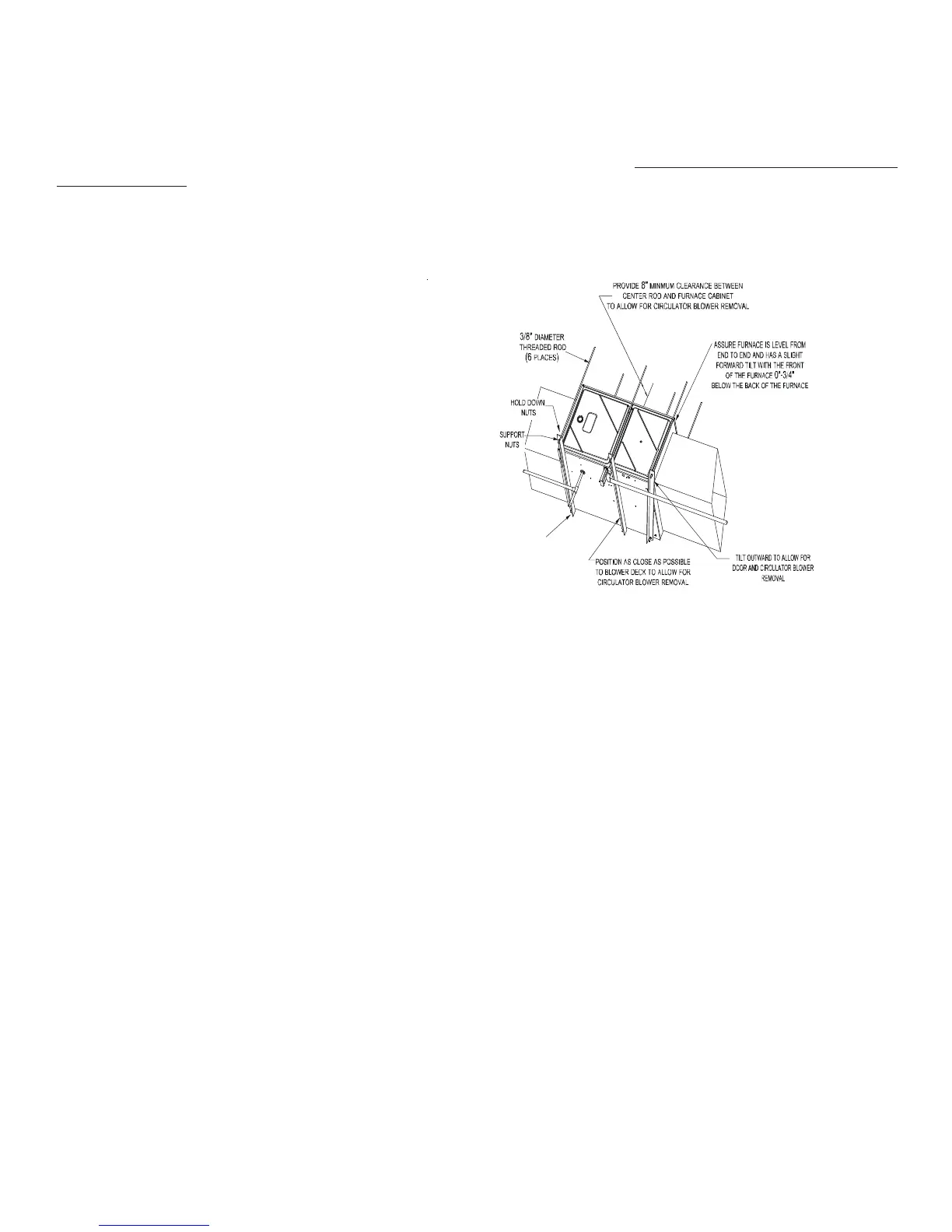

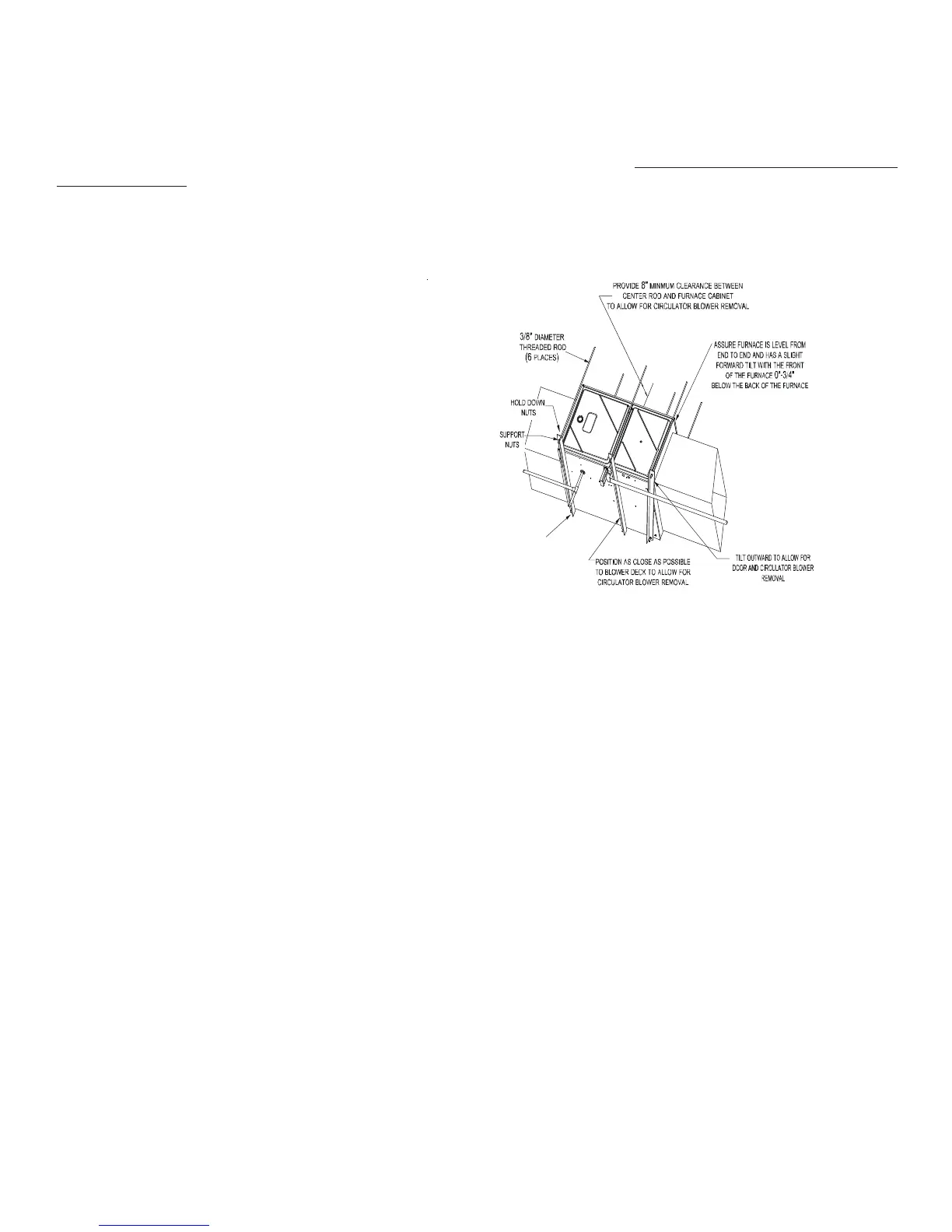

FURNACE S USPENSION

If suspending the furnace from rafters or joists, use 3/

8" threaded rod and 2”x2”x1/8” angle iron as shown in

the following diagram. The length of rod will depend on

the application and the clearances necessary.

If the furnace is installed in a crawl space it must be

suspended from the floor joist or supported by a con-

crete pad. Never install the furnace on the ground or

allow it to be exposed to water.

FRONT COVER PRESSURE SWITCH TUBE LOCATION

When an upflow model is installed horizontally with

left side down or a counterflow model is installed

horizontally with right side down, the front cover

pressure switch tube must be re-located to the lower port of the collector box cover.

1. Remove tube from front cover pressure switch and collector box cover.

2. Remove rubber plug from bottom collector box port and install on top collector box port.

3. Locate 24” x 1/4” tube in parts bag.

4. Install one end on front cover pressure switch.

5. Route tube to lower port on collector box cover and cut off excess tubing.

DRAIN TRAP AND LINES

In horizontal applications the condensate drain trap is secured to the furnace side panel, suspending it below the furnace. A minimum

clearance of 5 ½” below the furnace must be provided for the drain trap. Additionally, the appropriate downward piping slope must

be maintained from the drain trap to the drain location. Refer to Condensate Drain Trap and Lines for further details. If the drain trap

and drain line will be exposed to temperatures near or below freezing, adequate measures must be taken to prevent condensate from

freezing.

LEVELING

Leveling ensures proper condensate drainage from the heat exchanger and induced draft blower. For proper flue pipe drainage, the

furnace must be level lengthwise from end to end. The furnace should have a slight tilt from back to front with the access doors

downhill from the back panel approximately 1/2 to 3/4 inches. The slight tilt allows the heat exchanger condensate, generated in

the recuperator coil, to flow forward to the recuperator coil front cover.

ALTERNATE VENT/FLUE AND COMBUSTION AIR CONNECTIONS

In horizontal installations provisions for alternate flue and combustion air piping are available for upflow furnaces with left discharge

and counterflow furnaces with right air discharge. This configuration allows the flue and combustion air piping to be run vertically

through the side of the furnace. Refer to the “Recommended Installation Positions” figure for further detail. The standard piping

connections may also be used in these positions. Refer to Vent/Flue Pipe and Combustion Air Pipe for details concerning the

conversion to the alternate vent/flue and combustion air connections.

2" 2" 3/8"

ANGLE

IRON

(3

PLACES

)

XX

Figure 2

Loading...

Loading...