28

AUXILIARY ALARM SWITCH:

The control is equipped with a 24VAC Auxiliary Alarm Input (12 inch purple / white wire attached to pin 6 of 15 pin connector)

which can be utilized with communicating mode setups (typically used for condensate switch wiring but could be used with

compatible C0

2

sensors or Fire Alarms).

Legacy mode use

In a legacy system (Non-communicating), this auxiliary alarm input is not operational. Any auxiliary alarm switch must be

used to interrupt Y1 signal either to IFC or to UC.

Communication mode use

This feature can be activated or deactivated through the thermostat user menus. By default, an AUX switch is normally

closed and opens when the water level in the evaporator coil base pan reaches a particular level. The control will respond by

turning off the outdoor compressor and display the proper fault codes. If the AUX switch is detected closed for 30 seconds,

normal operation resumes and error messages are no longer displayed. Installer must wire control voltage (24VAC) to AUX

switch to ensure the Auxiliary Alarm Input has 24VAC during normal operation.

G

AS

S

UPPLY

AND

P

IPING

The furnace rating plate includes the approved furnace gas input

rating and gas types. The furnace must be equipped to operate

on the type of gas applied. This includes any conversion kits

required for alternate fuels and/or high altitude.

Inlet gas supply pressures must be maintained within the ranges

specified in the following table. The supply pressure must be

constant and available with all other household gas fired appli-

ances operating. The minimum gas supply pressure must be main-

tained to prevent unreliable ignition. The maximum must not be

exceeded to prevent unit overfiring.

HIGH ALTITUDE DERATE

When this furnace is installed at high altitude, the appropriate High Altitude orifice kit must be applied. This is required due to the

natural reduction in the density of both the gas fuel and combustion air as altitude increases. The kit will provide the proper design

certified input rate within the specified altitude range.

High altitude kits are purchased according to the installation altitude and usage of either natural or propane gas. Consult the

furnace Specification Sheet for appropriate kits.

Do not derate the furnace by adjusting the manifold pressure to a lower pressure than specified on the furnace rating plate. The

combination of the lower air density and a lower manifold pressure will prohibit the burner orifice from drawing the proper amount of

air into the burner. This may cause incomplete combustion, flashback, and possible yellow tipping.

In some areas the gas supplier may artificially derate the gas in an effort to compensate for the effects of altitude. If the gas is

artificially derated, the appropriate orifice size must be determined based upon the BTU/ft

3

content of the derated gas and the

altitude. Refer to the National Fuel Gas Code, NFPA 54/ANSI Z223.1, and information provided by the gas supplier to determine the

proper orifice size.

A different pressure switch may be required at high altitude regardless of the BTU/ft

3

content of the fuel used. Consult the furnace

Specification Sheet for pressure switch.

PROPANE GAS CONVERSION

This unit is configured for natural gas. The appropriate

manufacturer’s propane gas conversion kit, must be applied for

propane gas installations. Refer to the Propane Gas and/or High

Altitude Installations for details.

Consult the furnace Specification Sheet for a listing of appro-

priate kits. The indicated kits must be used to insure safe and

proper furnace operation. All conversions must be performed by a

qualified installer, or service agency.

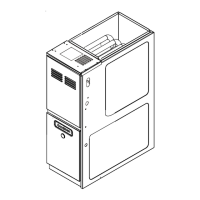

CAUTION

T

O

PREVENT

UNRELIABLE

OPERATION

OR

EQUIPMENT

DAMAGE

,

THE

INLET

GAS

SUPPLY

PRESSURE

MUST

BE

AS

SPECIFIED

ON

THE

UNIT

RATING

PLATE

WITH

ALL

OTHER

HOUSEHOLD

GAS

FIRED

APPLIANCES

OPERATING

.

Natural Gas Minimum: 4.5" w.c. Maximum: 10.0" w.c.

Propane Gas Minimum: 11.0" w.c. Maximum: 13.0" w.c.

INLET GAS SUPPLY PRESSURE

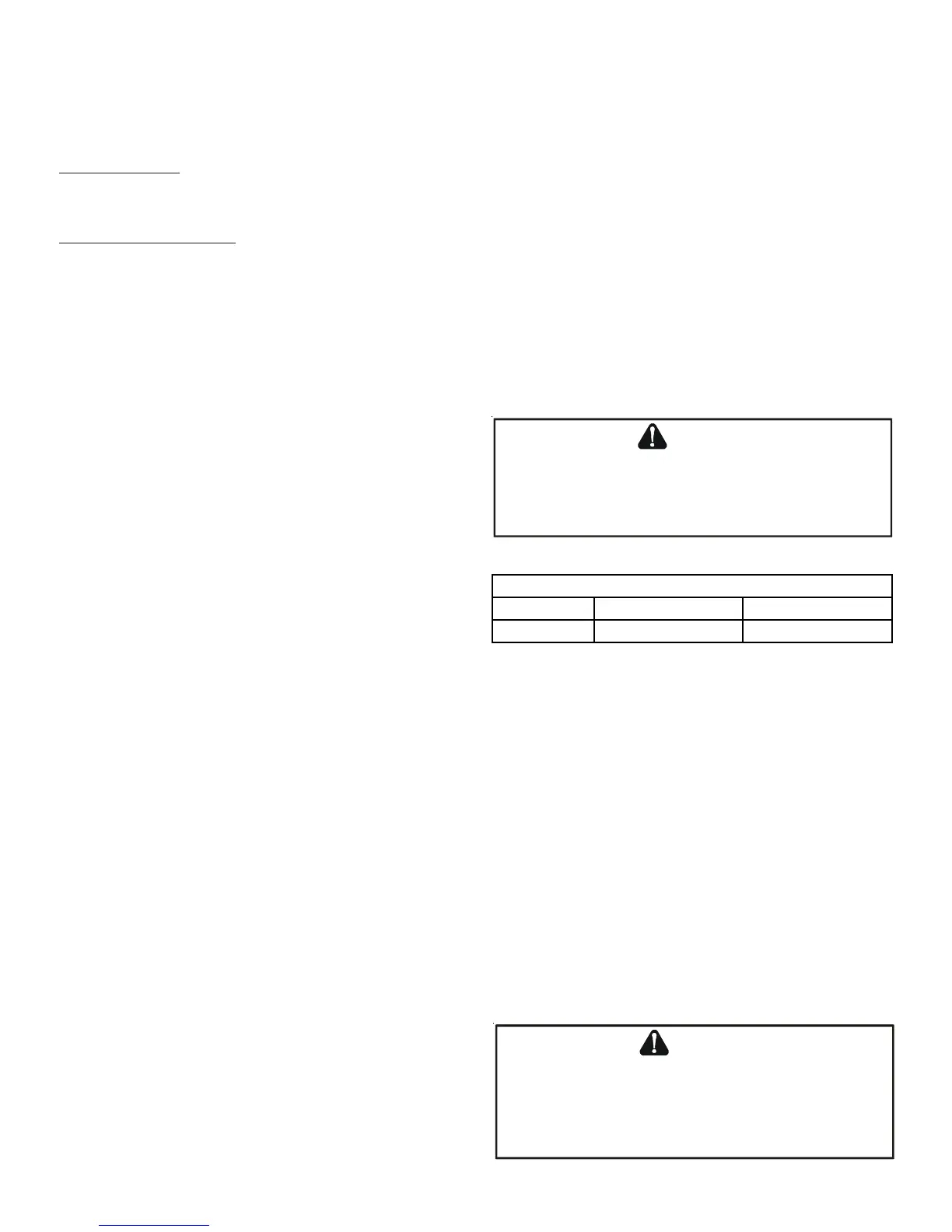

WARNING

P

OSSIBLE

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

MAY

OCCUR

IF

THE

CORRECT

CONVERSION

KITS

ARE

NOT

INSTALLED

. T

HE

APPROPRIATE

KITS

MUST

BE

APPLIED

TO

ENSURE

SAFE

AND

PROPER

FURNACE

OPERATION

. A

LL

CONVERSIONS

MUST

BE

PERFORMED

BY

A

QUALIFIED

INSTALLER

OR

SERVICE

AGENCY

.

Loading...

Loading...