Installation

14 3A9286B

Install Accessories

Install Monitoring Accessories

Install the following accessory to monitor equipment

performance.

• Leak Sensor: Monitors for leaks in the pump due

to diaphragm rupture. Automatically stops pump

operation and triggers the LED Indicator if a leak is

detected. Not provided with the equipment.

Accessory kits are available (purchase separately).

See Related Manuals, page 2.

Install Fluid Line Accessories

Install the following accessories in the order shown in

F

IG. 3 and FIG. 4, using adapters as needed.

• Fluid drain valve (G): Required. Relieves fluid

pressure in the system.

• Fluid shutoff valve (H): Shuts off fluid flow.

• Fluid pressure gauge (M): For more precise

adjustment of the fluid pressure.

• Fluid outlet line (J): Required. To dispense fluid.

• Fluid supply line (F): Required. Enables the

equipment to draw fluid from a container.

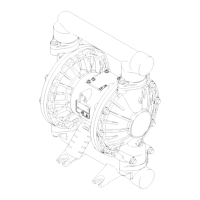

Install Fluid Leak Line Accessories

If a leak sensor is not installed in the pump, install the

following accessory as shown in F

IG. 6, using adapters

as needed.

NOTE: To monitor for leaks in the pump due to

diaphragm rupture, install a leak sensor. See Install

Monitoring Accessories, page 14.

• Fluid Leak line (L2): Routes fluid to a drain location

if fluid leaks due to diaphragm rupture.

1. Remove the plugs (if applicable) in the diaphragm

access ports (L).

2. Install conductive, flexible fluid leak lines (L2) to the

diaphragm access ports (L).

3. Route the fluid leak lines (L2) to a grounded end

container (L3) to catch leaking fluid. Follow local

codes and regulations for grounding.

NOTE: For Models in Explosive Atmospheres or

Hazardous (Classified) Locations): Ensure the

end container is grounded and located in a

non-explosive or non-hazardous environment.

FIG. 6: Typical Installation of Fluid Leak Lines

NOTICE

To avoid pump damage, install a leak sensor to

detect leaks in the equipment due to diaphragm

rupture.

If a leak sensor is not installed in the pump and the

diaphragm ruptures, the equipment will fill with fluid

or fluid will drain into the work area. To avoid injury

from leaking fluid, toxic fluid, toxic fumes, splashing

fluid, or hot fluid, install fluid drain lines to route fluid

leaks due to diaphragm rupture.

NOTICE

To avoid pump damage due to diaphragm rupture,

install a leak sensor to detect leaks in the equipment

and automatically stop pump operation. See Install

Monitoring Accessories, page 14.

NOTICE

The pump can be damaged if flexible fluid lines are

not used. If hard-plumbed fluid lines are used in the

system, use a short length of conductive, flexible

fluid line to connect to the pump.

Explosive Atmosphere or

Hazardous (Classified)

Location Ordinary Location

L2

L3

L

L

Triplex Sales

1-847-839-8442

www.triplexsales.com

Loading...

Loading...