Repair

32 3A9286B

Repair the Check Valves

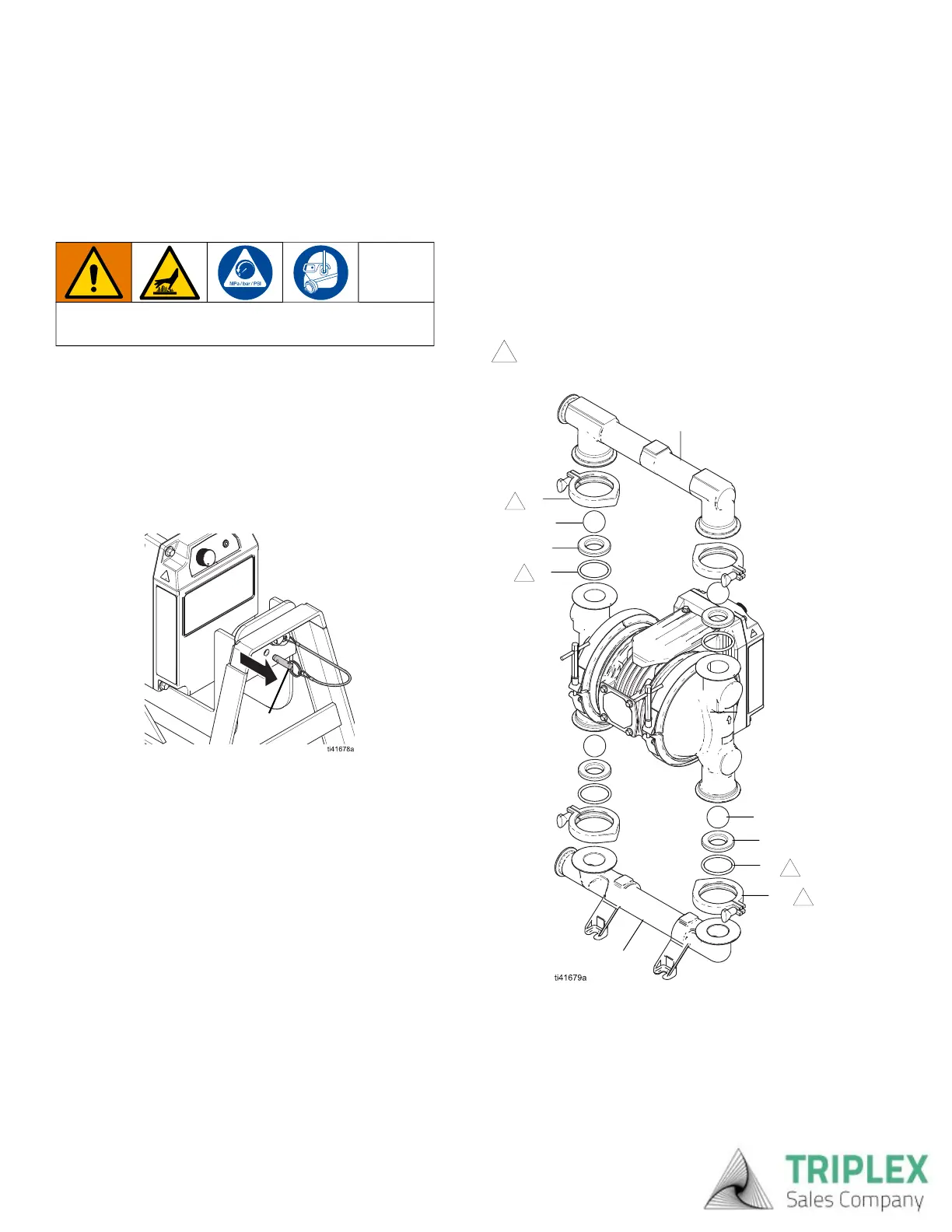

See FIG. 12–FIG. 13.

Disassemble Check Valves

1. Follow Prepare Equipment for Repair, page 31.

2. Drain the equipment.

For equipment with a rotating stand: Remove the

quick-release pins (29b) and rotate the equipment

to drain. See F

IG. 12.

NOTE: After draining, rotate the equipment to

positions which will aid disassembly.

FIG. 12: Quick Release Pin, Rotating Stand

3. On the outlet manifold (4), remove all clamps (7a).

4. Remove the outlet manifold (4), seals (10, if

applicable), checks (9), and seats (8).

NOTE: Use care while removing manifolds to avoid

damage to check valve components.

5. On the inlet manifold (5), remove all clamps (7a).

6. Remove the inlet manifold (5), seals (10, if

applicable), checks (9), and seats (8).

NOTE: Use care while removing manifolds to avoid

damage to check valve components.

7. Clean and inspect parts for wear or damage.

Replace as needed.

Reassemble Check Valves

1. Align and place seats (8), checks (9), seals (10, if

applicable), and manifolds (4, 5), exactly as shown

for your equipment model. See your related parts

manual. See Related Manuals, page 2.

2. Use the clamps (7a) to loosely attach the manifolds

(4, 5) to the fluid covers (3). After all components

are properly aligned, securely tighten the clamps

(7a).

FIG. 13: Check Valves

To avoid severe burns, do not touch hot fluid or hot

equipment.

29b

4

5

9

8

10

9

8

10

7a

3

7a

2

Lubricate clamps (7a) and seals (10) with a

waterproof, sanitary lubricant.

2

2

Triplex Sales

1-847-839-8442

www.triplexsales.com

Loading...

Loading...